Вывод сечения

Доступны два типа вывода сечения.

Первый — это вывод истории времени /TH/SECTIO, состоящий из суммы

силы и моментов, действующих на сечение. Вывод может быть в

глобальной системе или локальной системе, при этом наиболее распространенным выводом являются

группы переменных, GLOBAL, LOCAL и CENTER.

Второй тип вывода — это смещения и необязательные сила и

момент для каждого узла в сечении, записанные в файл выходных данных сечения SC01.

Затем этот файл можно прочитать как наложенное смещение,

примененное ко второй модели сечения разреза. Методология RD-E: 5400 Cut — это

пример методологии сечения разреза, которую можно использовать. В этом

случае полная модель запускается с ISAVE =1 или 2 для сохранения

перемещения и, при необходимости, результирующих сил/моментов сечения в

файле file_nameSC01.

Затем создается вторая модель разреза (подмодель) с разделом, определенным с помощью опции ISAVE =100 или 101 для чтения смещения узлов файла раздела. Локальная система раздела, определяемая тремя узлами node_ID1, node_ID2 и node_ID3 или frame_ID, должна быть той же, которая использовалась при сохранении данных (ISAVE =1 или 2) и чтении данных (ISAVE =100 или 101).

Если ISAVE =2 используется в полной модели, а ISAVE =101

используется в модели разреза, то PRADIOS выводит разницу между

результирующими силами и моментами сечения в полной и разрезной модели в

сечении (/TH/ SECTIO).

Для улучшения времени решения и уменьшения необходимой памяти рекомендуется установить ISAVE =0, если методология моделирования разреза не требуется.

Фильтр

При считывании и применении смещений к модели сечения разреза, смещение можно отфильтровать с помощью фильтра экспоненциального скользящего среднего. Например, отфильтрованное смещение в направлении x будет:

Где,

\(x_{f}\) Фильтрованное смещение

\(\alpha\) Константа фильтрации экспоненциального скользящего среднего

\(x(t)\) Неотфильтрованное смещение в текущий момент времени

\(x(t-dt)\) Смещение на предыдущем временном шаге

Рекомендации:

\(\alpha =\frac{2\pi dt}{T}\) для фильтрации -3 дБ

\(\alpha =\frac{2\pi dt}{\sqrt{3T}}\) для фильтрации -6 дБ

Где,

\(T\) Период фильтрации

\(dt\) Шаг времени модели

Период фильтрации \(T = 10\Delta t\) часто используется, что делает \(\alpha =\frac{2\pi}{10}\) = 0,62832 для фильтра -3 дБ.

Материалы

Различные испытания материалов могут привести к различным механическим характерам материала.

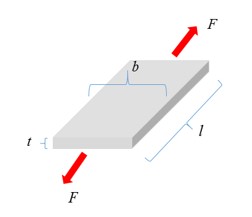

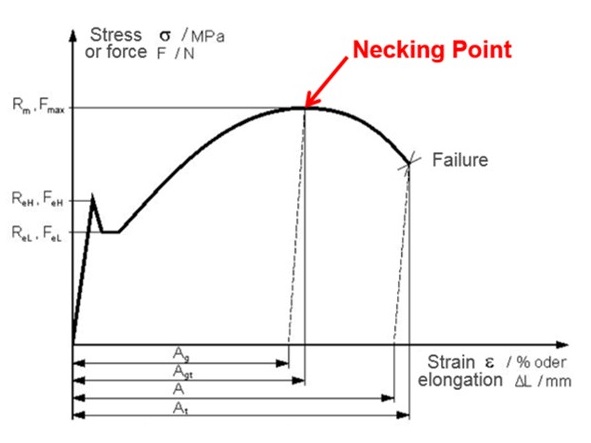

Типичным испытанием материала для металла является испытание на растяжение. С помощью этого испытания можно наблюдать кривую напряжения и деформации, предел текучести, точку сужения и точку разрушения материала.

- width

2.10018in

- height

1.80849in

Рисунок 131: Измеряются сила (F) и длина (l)

Инженерная кривая деформации-напряжения может быть сгенерирована следующим образом:

Где,

\(S_{0}\) Площадь сечения в исходном состоянии

\(I_{0}\) Начальная длина

В этой кривой сила-удлинение или инженерной кривой напряжение-деформация важны три точки.

Предел текучести: где материал начинает течь. До текучести можно предположить, что материал находится в упругом состоянии (можно измерить модуль Юнга E), а после текучести — пластическая деформация материала, которая необратима.

Некоторые материалы в этом тесте сначала достигнут верхнего предела текучести (ReH), а затем упадут до нижнего предела текучести (ReL). На инженерной кривой напряжения-деформации можно взять нижний предел текучести (консервативное значение).

Некоторые материалы не могут легко найти предел текучести. Возьмите напряжение 0,1 или 0,2% пластической деформации в качестве предела текучести.

Точка сужения: где материал достигает максимального напряжения на инженерной кривой напряжения-деформации. После этой точки материал начинает размягчаться.

Точка разрушения: где материал разрушился.

- width

5.15045in

- height

3.83367in

Рисунок 132:

\(\mathbf{R_{m}}\) Максимальное сопротивление

\(\mathbf{F_{max}}\) Максимальная сила

\(\mathbf{R_{eH}}\) Верхний предел текучести

\(\mathbf{R_{eL}}\) Нижний предел текучести

\(\mathbf{A_{g}}\) Равномерное удлинение

\(\mathbf{A_{gt}}\) Общее равномерное удлинение

\(\mathbf{A_{t}}\) Полная деформация разрушения

Истинная кривая напряжения-деформации, которая требуется для большинства материалов в

PRADIOS, за исключением LAW2, где как инженерное напряжение-деформация, так и истинное напряжение-деформация возможны для ввода данных о материалах.

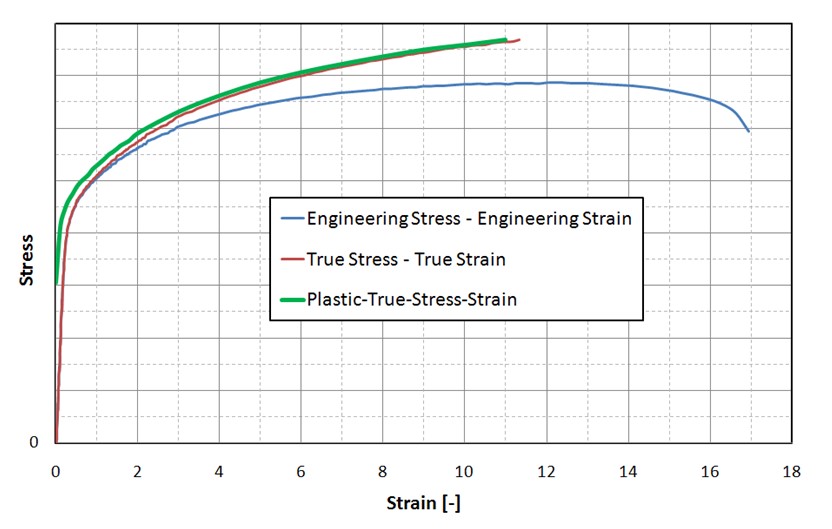

На рисунке 133 найдите инженерную кривую напряжения-деформации (синюю) с помощью:

Результатом является истинная кривая напряжения-деформации (красная). Пластическая истинная кривая напряжения-деформации показана зеленым цветом, где пластическая деформация начинается с 0. Эта зеленая кривая пластического истинного напряжения-деформации - то, что вам нужно,

как в LAW36, LAW60, LAW63 и так далее.

- width

6.93393in

- height

4.40872in

Рисунок 133:

Истинная кривая напряжения-деформации действительна до точки сужения материала. После точки сужения кривая материала должна быть определена вручную для закалки. Используя другой закон материала, PRADIOS экстраполирует истинную кривую напряжения-деформации до 100%.

Линейная экстраполяция: если кривая напряжения-деформации является входной функцией (

LAW36), то кривая напряжения-деформации линейно экстраполируется с наклоном, определяемым двумя последними точками кривой. Рекомендуется, чтобы список значений абсциссы был увеличен до значения, большего, чем предыдущее значение абсциссы.Джонсон-Кук: после точки шейки упрочнение Джонсона-Кука является одним из наиболее часто используемых для экстраполяции истинной кривой напряжения-деформации.

Однако это может переоценить деформационное упрочнение для автомобильной стали. В этом случае комбинация упрочнения Свифта-Воуса будет более точной.

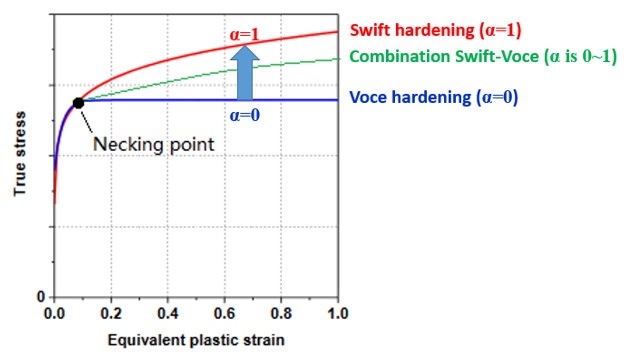

Swift и Voce: после точки шейки используйте одно из следующих уравнений для экстраполяции истинной кривой напряжения-деформации.

- Модель Swift

\(\sigma_{y}=A\left(\varepsilon_{p}+\varepsilon_{0}\right)^{n}\)

\(A\text{ и } n \text{ положительны.}\)

- Модель Voce

\(\sigma_{y}=k_{0}+Q\left[1-\exp\left(-B\varepsilon_{p}\right)\right]\)

\(k_{0,}Q и B\) положительны

\(\sigma_{y}=\alpha\big{[}A\big{(}\overline{\varepsilon}_{p}+\varepsilon_{0}\big{)}^{n}\big{]}+(1-\alpha)\big{\{}{k_{0}+Q\big{[}1-exp\big{(}-B\overline{\varepsilon}\{p}\big{)}\big{]}\big{\}}\)

Figure 134:

Здесь α — вес упрочнения Swift и упрочнения Voce. Вот один Скрипт Compose в качестве примера для подгонки параметров упрочнения Swift \(A,\varepsilon_{0}, n\) и параметров упрочнения Voce \(k_{0,} Q, B\) с входной кривой напряжения-деформации.

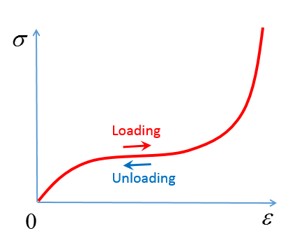

Гиперупругие материалы

Гиперупругие материалы используются для моделирования материалов, которые реагируют упруго при очень больших деформациях. Эти материалы обычно показывают нелинейную упругую, несжимаемую реакцию деформации напряжения, которая возвращается в исходное состояние при разгрузке.

Рисунок 135:

Гиперупругие материалы являются частным случаем материала Коши, где напряжение зависит только от текущей деформации. Кинетическая теория Мейера описывает, как эти материалы состоят из гибкой цепочечной структуры, которая вращается и выпрямляется при деформации. Это привело к теории, согласно которой функция плотности энергии деформации может быть записана как функция деформации.3 Плотность энергии деформации затем может быть дифференцирована для получения поведения напряжения-деформации материала. Наиболее распространенными гиперэластичными материалами являются эластомеры или резины. Некоторые свойства эластомеров включают.2

Материал почти идеально эластичен, а деформация обратима, причем напряжение является функцией только текущей деформации и не зависит от истории или скорости нагрузки, если деформируется при постоянной температуре или адиабатически.

Материал несжимаем и сильно сопротивляется изменениям объема. Модуль объемной упругости, который является отношением изменения объема к гидростатическому компоненту напряжения, сопоставим с модулем металлов.

Материал очень слаб при сдвиге, его модуль сдвига в 10-5 раз меньше, чем у большинства металлов.

Материал изотропен, его реакция напряжения-деформации не зависит от ориентации материала.

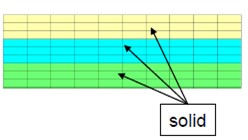

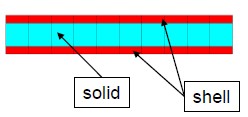

Рекомендации по свойствам элемента

При использовании гиперупругих материальных законов есть некоторые рекомендуемые

настройки свойств элементов. При использовании твердых элементов всегда

лучше создавать сетку с 8-узловыми элементами /BRICK, если это возможно. Если нет, то можно использовать элементы /TETRA4 или /TETRA10. Рекомендуемые /PROP/SOLID для

8-узлового кирпича: \(I_{smstr}\) =10, \(I_{cpre}\) =1, с

\(I_{solid}\) =24. Если возникает эффект песочных часов, то можно использовать \(I_{solid}\) =17 с

\(I_{frame}\) =2.

Treloar, L. R. G. “The elastic and related properties of rubbers”. Reports on progress in physics 36, no. 7 (1973): 755

Боуэр, Аллан Ф. Прикладная механика твердых тел. CRC press, 2009

Ogden Materials

Гиперупругие материалы можно использовать для моделирования изотропного, нелинейного упругого поведения резины, полимеров и подобных материалов. Эти материалы практически несжимаемы в своем поведении и могут быть растянуты до очень больших деформаций.

В PRADIOS материальные законы LAW42, LAW62, LAW69, LAW82 и LAW88 используют различные функции плотности энергии деформации модели материалов Огдена5 для моделирования гиперупругих материалов.6

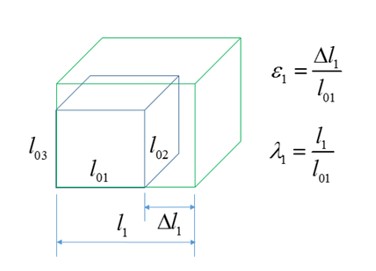

Определение материала

Растяжение (также называемое коэффициентом растяжения) \(\lambda\) — это отношение конечной длины и начальной длины. Используется для материалов с большими деформациями. Для куба при растяжении:

\(\varepsilon_{1}=\frac{\Delta I}{I_{01}}\) Техническая деформация (также называемая номинальной деформацией) в направлении 1

\(\lambda_{1}=\frac{I_{1}}{I_{01}}\) Прочность в направлении 1

Рисунок 136:

Таким образом, деформация и растяжение связаны следующим образом:

Основное растяжение \(\lambda_{i}\) можно использовать для описания объемной деформации путем расчета относительного объема J, вычисляемого как:

Для несжимаемого материала объем не должен меняться и, таким образом, =1 и, таким образом, растяжение можно рассчитать для следующих испытаний материалов.

Одноосный тест:

\(\lambda_{1}=\lambda\text{ и }\lambda_{2}=\lambda_{3}2=\frac{1}{\lambda}\)

Двуосный тест:

\(\lambda_{1}=\lambda_{2}=\lambda и (\lambda_{3}=\lambda^{-2})\)

Плоскостной (сдвиговой) тест:

\(\lambda_{1}=\lambda; \lambda_{3}=1 и (\lambda_{2}=\lambda^{-1})\)

/MAT/LAW42 (Ogden)

Эта модель материала определяет гиперупругий, вязкий и несжимаемый материал, заданный с использованием моделей материалов Огдена, Нео-Хука или Муни-Ривлина. Этот закон обычно используется для моделирования несжимаемых резин, полимеров, пен и эластомеров. Этот материал может использоваться с оболочечными и твердыми элементами.

LAW42 использует следующее представление плотности энергии деформации материальной модели Огдена.

Где,

\(W\) Плотность энергии деформации

\(\lambda_{1}\) \(i_{th}\) главный инженерный участок

\(J\) Относительный объем определяется как: \(J=\lambda_{1}\cdot\lambda_{2}\cdot\lambda_{3}=\frac{\rho_{0}}{\rho}\)

\(\vec{\lambda}_{i}=J^{\frac{1}{3}}\lambda_{i}\) Deviatoric stretch

\(\alpha_{p} and mu_{p}\) Пары коэффициентов материальных констант.

Можно определить до 5 пар констант материала.

Начальный модуль сдвига и объемный модуль (K) определяются следующим образом:

и

Где, \(v\) — коэффициент Пуассона, который используется только для вычисления модуля объемной упругости.

Параметры материала

Параметры \(\alpha\) и \(\mu\) должны быть выбраны так, чтобы начальный модуль сдвига был:

Для стабильности материала требуется, чтобы каждая пара констант материала

В общем случае модель Огдена можно использовать для деформаций до 700%. Количество необходимых пар терминов материалов, \(\alpha\) и \(\mu\), зависит от диапазона экспериментальных данных, которые подходят, и точности подгонки кривой

желаемой. На практике 3 пары материалов подходят для большинства данных. Если пары материалов не известны для конкретного материала, то подгонка кривой данных одноосных испытаний может быть выполнена в PRADIOS с использованием LAW69 или с помощью отдельного программного обеспечения для подгонки.

Модель Neo-Hookean

Простым случаем модели материала Огдена является модель Нео-Хукена, представленная с использованием следующего уравнения для функции плотности энергии деформации:

Где,

\(I_{1}\) Первые инварианты правого тензора Коши-Грина

\(C_{10}\) Материальная константа

Это представление можно вывести из функции плотности энергии деформации Огдена LAW42, когда:

\(\mu_{1}=2\cdot C_{10}:\alpha_{1}=2, и\mu_{2}=\alpha_{2}=0\)

Модель Нео-Хукена является простой моделью, которая обычно точна только для деформаций менее 20%.

Модель Муни-Ривлина

Немного более сложным случаем модели материала Огдена LAW42 является модель Муни-Ривлина, которую можно представить с помощью следующего уравнения для функции плотности энергии деформации:

Где,

\(I_{1}\) и \(I_{2}\) Первый и второй инварианты правого тензора Коши-Грина

\(C_{10}\) и \(C_{01}\) Константы материала

Это представление можно вывести из функции плотности энергии деформации Огдена LAW42, когда:

\(\mu_{1}=2\cdot C_{10},\mu_{2}=-2\cdot C_{01}, \alpha_{1}=2 и \alpha_{2}=\cdot 2\)

Константы Муни-Ривлина можно получить у поставщика материалов или испытательной компании. Если они недоступны, то можно выполнить подгонку кривой данных одноосных испытаний в PRADIOS с помощью LAW69 или с помощью отдельного программного обеспечения для подгонки. Закон материала Муни-Ривлина точен для деформаций до 100%.

Коэффициент Пуассона и несжимаемость материала

Если материал действительно несжимаем, то \(v\) = 0,5. Однако на практике это невозможно использовать, поскольку это приведет к бесконечному объемному модулю, бесконечной скорости звука и, следовательно, бесконечно малому шагу времени твердого элемента.

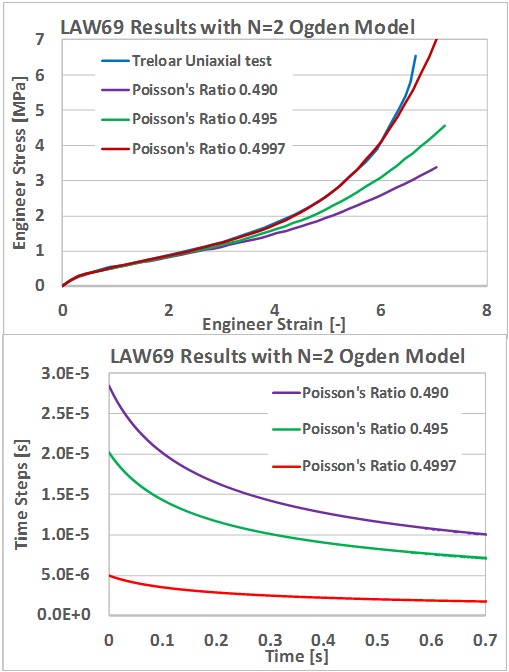

Влияние различных входных значений коэффициента Пуассона можно увидеть на рисунке 137. Самая большая разница в результатах наблюдается при более высоких значениях деформации. Результаты будут лучше соответствовать данным испытаний, когда (v=0,4997), но это приводит к временному шагу, который в 4 раза меньше, чем (v=0,495). Таким образом, чтобы сбалансировать время вычисления и точность, рекомендуется использовать (v=0,495) для несжимаемого резинового материала.

Влияние коэффициента Пуассона и объемного модуля упругости аналогично в других законах материалов Огдена.

Рисунок 137:

Более высокие значения коэффициента Пуассона могут привести к очень малому временному шагу или расхождению для явных симуляций.

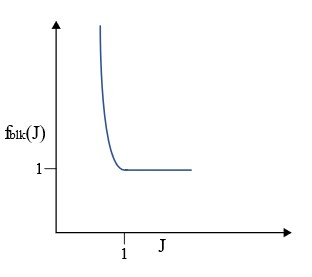

В LAW42 несжимаемость материала обеспечивается с помощью подхода штрафа, который вычисляет давление, пропорциональное изменению плотности.

Где,

\(K\) Модуль объемной упругости

\(J=\frac{V}{V_{0}}=\frac{m\rho_{0}}{m\rho}=\frac{\rho_{0}}{\rho}\) Относительный объем, который упрощается до относительной плотности, если масса постоянна

\(\mathrm{f}_{blk}(J)\) Коэффициент масштабирования коэффициента объемной упругости в зависимости от функции относительного объема

\(Fscale_{blk}\) Коэффициент масштабирования абсциссы для функции \(F_{blk}(J)\)

Модуль объемной упругости (K) гиперупругих материалов обычно имеет очень

высокое значение, которое обеспечивает необходимое сопротивление давлению для поддержания

состояния несжимаемости (J=1). Но если материал начинает

сжиматься (j < 1), то модуль объемной упругости можно увеличить, включив

входную функцию fct_IDblk, которая позволяет масштабировать значение коэффициента объемной упругости как функцию . По умолчанию масштабирование отсутствует; таким образом, если идентификатор функции равен нулю, а значение функции

масштабирования объемной упругости равно 1. Рекомендуется вывести

(/ANIM/BRICK/DENS) и просмотреть плотность материала

компонентов LAW42, чтобы убедиться, что изменение плотности мало, то есть значение J близко к 1, а материал несжимаем.

- width

2.60022in

- height

2.30853in

Рисунок 138: Функция масштабного коэффициента модуля объемной упругости fct_IDblk

Влияние вязкости (скорости)

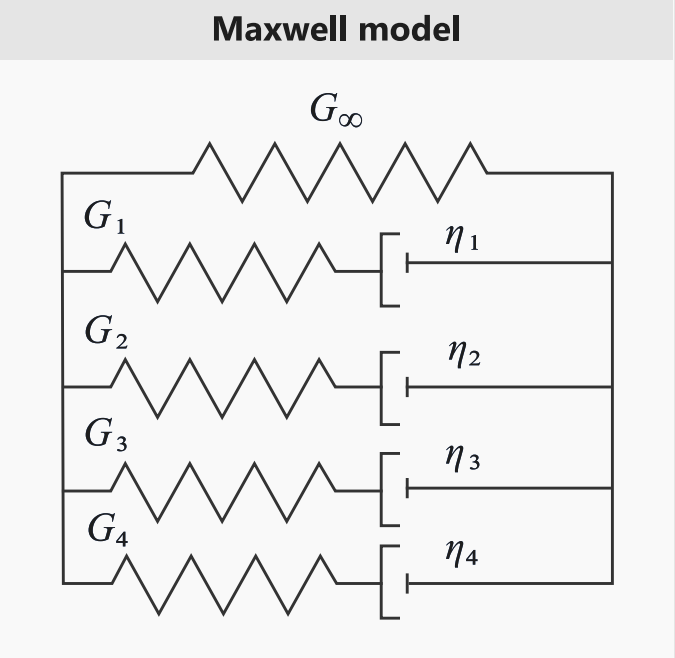

Вязкие (скоростные) эффекты моделируются в LAW42 с использованием модели Максвелла, которую можно описать упрощенно как систему \(\eta\) пружин с жесткостью’ \(G_{i}\) и демпферов \(\eta_{i}\):

- width

2.60022in

- height

2.30853in

Рисунок 139: Модель Максвелла

Модель Максвелла представлена с использованием входных данных ряда Прони (\(G_{i},\tau_{i})\). Гиперупругий начальный модуль сдвига \(\mu\) такой же, как и долгосрочный модуль сдвига \(G_{\infty}\) в модели Максвелла, а \(\tau_{i}\) — это время релаксации:

Значения \(G_{i} и \tau_{i}\) должны быть положительными.

/MAT/LAW62 (VISC_HYP)

Закон гипервязкоупругого материала в PRADIOS, который можно использовать для моделирования полимеров и эластомеров.

Гиперупругое поведение в этом материальном законе определяется с помощью следующей функции плотности энергии деформации:

Где,

\(W\) Плотность энергии деформации

\(\lambda_{i}\) \(i_{th}\) главный stretch

\(J\) Относительный объем, определенный в уравнении 67

\(\beta=\frac{v}{(1-2v)}\)

\(\alpha_{i}\) и \(\mu_{i}\) Пары коэффициентов материальных констант.

Можно определить до 5 пар материальных констант.

Коэффициент Пуассона должен быть (0<v<0,5). Этот закон можно использовать для моделирования сжимаемых или иногда называемых гиперпенистых материалов, задавая низкое значение коэффициента Пуассона.

Примечание: Коэффициенты материала \(\mu_{i}\) различны, но их можно преобразовать с помощью:

Примечание: Коэффициенты материала \(\mu_{i}\) различны, но их можно преобразовать с помощью:

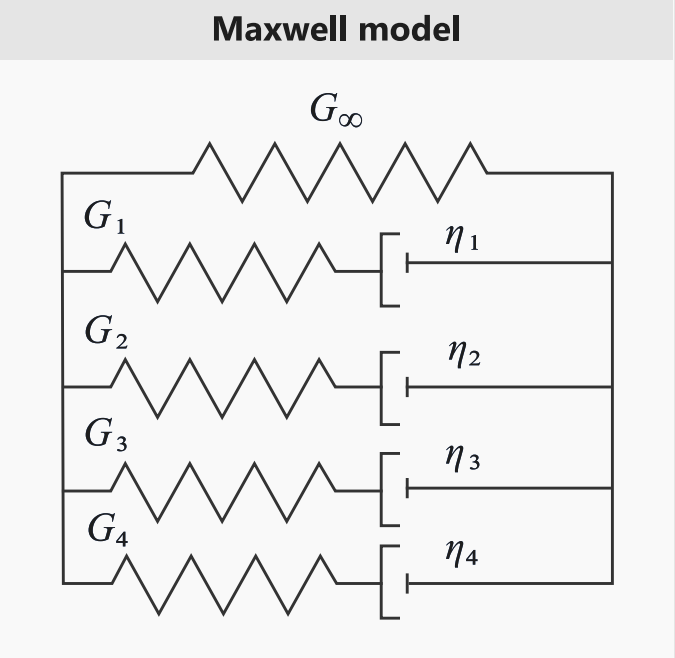

Влияние вязкости (скорости)

Вязкие (скоростные) эффекты моделируются в LAW62 с использованием модели Максвелла, которую можно описать упрощенно как систему из n пружин с жесткостью \(G_{i}\) и демпферов \(\eta_{i}\).

- width

2.60022in

- height

2.30853in

Рисунок 140: Модель Максвелла

Модель Максвелла представлена с использованием ряда Прони с входными данными. Начальный модуль сдвига равен:

Сумма \(\mu_{i}\) должна быть больше 0.

Коэффициент жесткости равен:

С учетом того,

Относительное время, \(\tau_{i}\) должно быть положительным:

Примечание: Когда вязкость включена, модуль сдвига в LAW62 является

начальным модулем сдвига

\(G_{0}=\sum_{i=1}^{N}\mu_{i}\),

который

включает вязкость, но в LAW42 модуль сдвига является

долгосрочным модулем сдвига, который не включает вязкость

\(G_{\omega}=\frac{\sum_{p=1}^{5}\mu_{p}\cdot a_{p}}{2}\).

Примечание: Когда вязкость включена, модуль сдвига в LAW62 является

начальным модулем сдвига

\(G_{0}=\sum_{i=1}^{N}\mu_{i}\),

который

включает вязкость, но в LAW42 модуль сдвига является

долгосрочным модулем сдвига, который не включает вязкость

\(G_{\omega}=\frac{\sum_{p=1}^{5}\mu_{p}\cdot a_{p}}{2}\).

/MAT/LAW69

Этот закон, как и /MAT/LAW42 (OGDEN), определяет гиперупругий и

несжимаемый материал, заданный с использованием моделей материалов Огдена или Муни-Ривлина. В отличие от LAW42, где параметры материала являются

вводными, этот закон вычисляет параметры материала, используя данные испытаний из

одноосной инженерной кривой напряжения-деформации.

Этот материал можно использовать с оболочечными и твердыми элементами.

Формулировка плотности энергии деформации, используемая в зависимости от law_ID:

law_ID = 1 (закон Огдена):

law_ID = 2 (закон Муни-Ривлина):

Параметры материала

После считывания кривой напряжения-деформации (fct_ID1) PRADIOS вычисляет соответствующие пары параметров материала, используя нелинейный алгоритм подгонки наименьших квадратов. Для классического закона Огдена, (law_ID=1), вычисляемые пары параметров материала равны и где значение p определяется через вход N_pair.

Максимальное значение равно N_pair=5 со значением по умолчанию 2. Обычно для хорошего соответствия требуется не более N_pair=3.

Для закона Муни-Ривлина (law_ID =2) параметр материала \(C_{10}\) и \(C_{01}\) рассчитываются для LAW42 Закон Огдена можно рассчитать с помощью этого преобразования:

\(\mu_{1}=2\cdot C_{10},\mu_{2}=-2\cdot C_{01},\alpha_{1}=2 и (\alpha_{2}=)-2\)

Минимальные входные данные испытаний должны представлять собой кривую деформации одноосного растяжения. Если доступны данные одноосного сжатия, то деформация должна монотонно увеличиваться от отрицательного значения при сжатии до положительного значения при растяжении. При сжатии деформация не должна быть меньше -1,0, поскольку деформация -100% физически невозможна.

Для улучшения качества нелинейной подгонки методом наименьших квадратов рекомендуется: - Кривая экспериментальных данных представляет собой гладкую монотонно возрастающую функцию с равномерным распределением точек абсциссы. Количество точек данных на кривой экспериментальных данных должно быть больше количества пар параметров (N_pair).

Инженерная деформация отрицательна при сжатии и положительна при растяжении. Для данных испытаний на сжатие инженерная деформация должна быть больше -1,0 (максимум 100% сжатия), но также можно использовать данные о деформации только при растяжении.

Если N_pair ≥ 3, то данные испытаний должны охватывать не менее 100% деформации растяжения и/или 50% деформации сжатия.

N_pair не следует устанавливать на очень большое значение, чтобы избежать нестабильности в процедуре подгонки.

Этот материальный закон стабилен, когда \(\mu_{p}\alpha_{p}>0\) (при (p)=1,…5) выполняется для пар параметров для всех условий нагрузки. По умолчанию Radios пытается подогнать кривую, учитывая эти условия (\(I_{check}=2)\). Если надлежащее соответствие не может быть найдено, то Radios использует более слабое условие (\(I_{check}=1\):), которое гарантирует, что начальный сдвиг гиперэластичный модуль (\(\mu\)) положительный. Чтобы определить, насколько хорошо рассчитанные параметры материала представляют входные данные испытаний, PRADIOS Starter выводит значение «усредненной ошибки подгонки», которое рекомендуется не превышать 10%. Для визуального сравнения кривая напряжения-деформации, рассчитанная на основе плотности энергии деформации и расчетных параметров материала, также выводится PRADIOS Starter.

Из-за трения, присутствующего в одноосном испытании на сжатие, обычно точнее брать равные данные испытаний на двухосное растяжение и преобразовывать их в одноосные данные сжатия, используя эти формулы 7 которые действительны для несжимаемых материалов.

Где,

\(\varepsilon_{c}\) Одноосное инженерное сжатие

\(\varepsilon_{b}\) Равная двухосная инженерная деформация растяжения

\(\sigma_{c}\) Одноосное инженерное напряжение сжатия

\(\sigma_{b}\) Равное двухосное инженерное напряжение растяжения

Несжимаемость материала

Материал LAW69 использует тот же метод для поддержания несжимаемости, что и LAW42. Для получения дополнительной информации см. Коэффициент Пуассона и Несжимаемость материала в LAW42.

Влияние вязкости (скорости)

/VISC/PRONY необходимо использовать с LAW69 для включения вязких эффектов. В качестве альтернативы LAW69 можно использовать для извлечения параметров Огдена или Муни-Ривлина, а затем эти параметры можно использовать в LAW42 с добавленной вязкостью.

/MAT/LAW82

Эта модель материала определяет гиперупругий и несжимаемый материал, указанный с использованием моделей материалов Огдена, Нео-Хукеана или Муни-Ривлина. Этот закон обычно используется для моделирования несжимаемых резин, полимеров, пен и эластомеров.

Этот материал можно использовать с оболочечными и твердыми элементами. По сравнению с LAW42 или LAW62, этот закон использует другую формулировку плотности энергии деформации Огдена, приведенную в уравнении 80. Формулировка плотности энергии деформации LAW82 соответствует той, которая используется в гиперупругой модели некоторых других решателей конечных элементов и, таким образом, параметры материала для этой формы плотности энергии деформации Огдена иногда доступны у поставщиков материалов или из других источников.

Где,

\(W\) Плотность энергии деформации

\(N\) Количество материальных констант \(\alpha_{i},\mu_{i}\) и \(D_{i}\)

\(\overline{\lambda}_{i}=J^{\frac{1}{3}}\lambda_{i}\) Девиаторное растяжение

\(J\) Относительный объем, как определено в уравнении 56

Начальный модуль сдвига:

Модуль объемной упругости рассчитывается как \(K=\frac{2}{D_{1}}\) на основе этих правил:

Если \(v=0\), следует ввести \(D_{1}\).

Если \(v\neq 0\), вход \(D_{1}\) игнорируется и будет пересчитан и выведен в выход Starter с использованием:

Если \(v=0\) и \(D_{1}\) =0, используется значение по умолчанию \(v=0.475\) и \(D_{1}\) вычисляется с использованием уравнения 82

Модель Нео-Хукена

Как и LAW42, LAW82 также можно упростить до модели Нео-Хукена с использованием:

\(\mu_{1}=2\cdot C_{10},\alpha_{1}=2) и \mu_{2}=\alpha_{2}=0\)

Модель Муни-Ривлина

Как и LAW42, LAW82 также можно упростить до модели Муни-Ривлина, используя:

\(\mu_{1}=2\cdot C_{10},\mu_{2}=2\cdot C_{01},\alpha_{1}=2 и \alpha_{2}=-2\)

Вязкие (скоростные) эффекты

``/VISC/PRONY``необходимо использовать с LAW82 для включения вязких эффектов.

Проверка устойчивости по условию Дрюкера

В LAW42 и LAW69 устойчивость по Дрюкеру автоматически вычисляется PRADIOS Starter.

Условие устойчивости по Дрюкеру проверяет, удовлетворяет ли изменение напряжения Кирхгофа, соответствующее бесконечно малому изменению логарифмической деформации (истинной деформации), следующему неравенству.

Где, i =1,2,3 главное направление.

При изменении логарифмической деформации

\(d\tau_{i}=J\cdot d\sigma_{i}\) Изменение напряжения Кирхгофа

\(d\tau=\mathbf{D}:d\varepsilon\) Соотношение между напряжением Кирхгофа и логарифмической деформацией

Условие устойчивости Дрюкера будет:

Здесь \(\mathbf{D}\) — матрица тангенциальной жесткости материала, а также наклон кривой напряжения-деформации:

Для стабильного материала требуется, чтобы тангенциальная жесткость материала \(\mathbf{D}\) была положительной (наклон кривой напряжения-деформации положительный). Тангенциальная матрица материала \(\mathbf{D}\) положительна, если выполняются следующие условия:

Напряжение Кирхгофа для модели Огдена равно:

Поскольку \(D_{ij}=\frac{\partial\tau_{i}}{\partial\lambda_{j}}\), тогда для заданного параметра Огдена \(\alpha_{p}\), \(\mu_{p}\) с условиями \(I_{1}>0, I_{2}>0 и I_{3}>0\), тогда можно было бы рассчитать диапазон деформации материала в стабильности по Друкеру. .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image-10.jpg

- width

6.65882in

- height

5.00868in

Рисунок 141:

Критерий стабильности Дрюкера вычисляет диапазон деформаций, при которых модель материала останется стабильной, исходя из заданных параметров материала. Эта проверка стабильности не может быть выполнена для каждой деформации, однако обычно её используют для оценки стабильности материала при однолучевой, двулучевой и плоскостной нагрузке.

Например, при использовании следующих параметров Огдена:

:math:mu_{1} = 13.99077258830 :math:alpha_{1} = 3.78819292935039

:math:mu_{2} = 9.13454532223 :math:alpha_{2} = 7.17617341059

:math:mu_{3} = 8.904655103235 :math:alpha_{3} = 7.27028137148

Тогда проверка стабильности Дрюкера будет автоматически выполнена в PRADIOS Starter, и результаты будут выведены в файл вывода Starter *0.out. В нем показывается деформация, при которой может возникнуть нестабильность для заданных параметров Огдена:

CHECK THE DRUCKER PRAGER STABILITY CONDITIONS

-----------------------------------------------

MATERIAL LAW = OGDEN (LAW42)

MATERIAL NUMBER = 1

TEST TYPE = UNIXIAL

COMPRESSION: UNSTABLE AT A NOMINAL STRAIN LESS THAN -0.3880000000000

TENSION: UNSTABLE AT A NOMINAL STRAIN LARGER THAN 0.9709999999999

TEST TYPE = BIAXIAL

COMPRESSION: UNSTABLE AT A NOMINAL STRAIN LESS THAN -0.2880000000000

TENSION: UNSTABLE AT A NOMINAL STRAIN LARGER THAN 0.2780000000000

TEST TYPE = PLANAR (SHEAR)

COMPRESSION: UNSTABLE AT A NOMINAL STRAIN LESS THAN -0.3680000000000

TENSION: UNSTABLE AT A NOMINAL STRAIN LARGER THAN 0.5829999999999

Примечание: Для материала Нео-Хука с \(C_{10}!>!0 (or \mu_{1}!>!0)\), материал всегда является стабильным, и критическое значение не определяется проверкой стабильности по Друкеру.

Примечание: Для материала Нео-Хука с \(C_{10}!>!0 (or \mu_{1}!>!0)\), материал всегда является стабильным, и критическое значение не определяется проверкой стабильности по Друкеру.

Для материала Мунни-Ривлина необходимо проверить стабильность по Друкеру, так как параметры \(C_{01} or \mu_{2}\) могут быть отрицательными, что ведет к нестабильности материала.

/MAT/LAW88

Этот закон использует табличные данные испытаний на однолучевое растяжение и сжатие с инженерским напряжением и деформацией при различных скоростях деформации для моделирования несжимаемых материалов. Он совместим только с твердыми элементами.

Материал основан на следующей функции энергии деформации Огдена, при этом не требуется подгонка кривых для извлечения констант материала, как в большинстве других гиперэластичных моделей. :sup:8

Вместо этого данный закон определяет функцию Огдена непосредственно из табличных данных кривой напряжение-деформация при однолучевом растяжении.

В отличие от других законов Огдена, модуль объема (Bulk Modulus) должен быть введен либо из экспериментальных данных, либо извлечен из результатов в Starter по кривой Огдена LAW69. При сравнении результатов между LAW42 или LAW69 и LAW88 необходимо использовать один и тот же модуль объема.

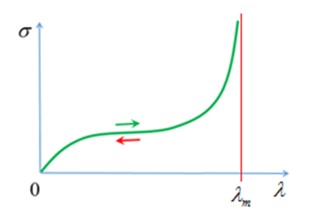

Поведение при разгрузке

Разгрузка может быть представлена с помощью функции разгрузки или путем задания гистерезиса и фактора формы в модели повреждения, основанной на энергии.

Если используется модель повреждения, кривые нагружения применяются как для загрузки, так и для разгрузки, а тензор напряжений при разгрузке уменьшается по формуле:

где

Здесь,

:math:W_{cur} — текущая энергия

:math:W_{max} — максимальная энергия, соответствующая квазистатическому поведению

Hys и Shape — параметры, заданные пользователем

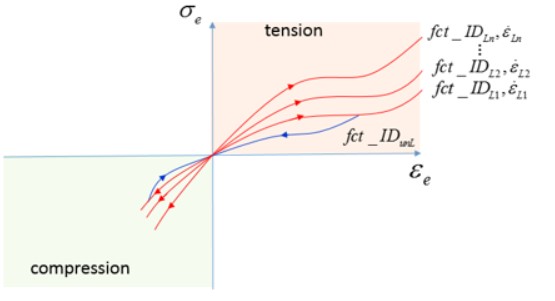

Если предоставлена кривая разгрузки, доступны следующие опции:

Растяжение Загрузка и разгрузка

= 0

*Рисунок 142:

При загрузке используется функция загрузки fct_IDLi

При разгрузке используется функция разгрузки fct_IDunL

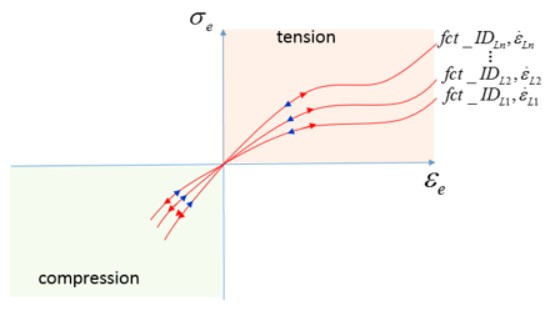

= 1

Рисунок 143:

При загрузке и разгрузке используется одна и та же функция fct_IDLi

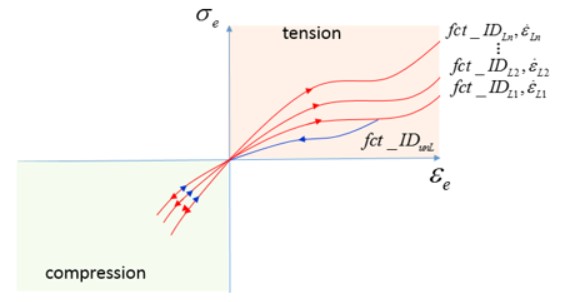

= -1

- width

5.20833in

- height

2.79878in

Рисунок 144:

При использовании функции загрузки fct_IDLi для растяжения

Растяжение (Тension)

Разгрузка использует функцию разгрузки fct_IDunL

Сжатие

Разгрузка использует загрузку fct_IDLi

Вязкость (Эффекты скорости

Эффекты скорости деформации можно смоделировать, включив данные испытаний на инженерное напряжение деформации при различных скоростях деформации. Это может быть проще, чем расчет параметров вязкости для традиционных моделей гиперупругого материала.

Вывод

Обязательно используйте закон материала, который наилучшим образом соответствует имеющимся данным испытаний.

Например, если доступны минимальные данные испытаний и деформации не слишком велики, можно использовать модель LAW42 NeoHookean. Если известно состояние нагрузки, важно иметь данные испытаний, которые представляют это состояние напряжения, и убедиться, что модель материала соответствует этим данным испытаний.

Ogden, R. W., and Non-linear Elastic Deformations. “Ellis Horwood”. Нью-Йорк (1984)

Miller, Kurt. “Testing Elastomers for Hyperelastic Material Models in Finite Element Analysis” Axel Products, Inc., Энн-Арбор, Мичиган (2017). Последнее изменение 5 апреля 2017 г.

Arruda-Boyce (/MAT/LAW92)

LAW92 описывает модель материала Арруды-Бойса, которую можно использовать для моделирования гиперупругого поведения. Эта модель основана на статистической механике материала с кубическим репрезентативным элементом объема, содержащим восемь цепей вдоль диагональных направлений.

Она предполагает, что молекулы цепи расположены в среднем вдоль диагоналей кубического в основном пространстве растяжения.

Параметры материала

Функция плотности энергии деформации:

Константа материала, \(c_{i}\) являются:

\(c_{1}=\frac{1}{2}, c_{2}=\frac{1}{20}, c_{3}=\frac{11}{1050}, c_{4}=\frac{19}{7000}, c_{5}=\frac{519}{673750}\)

\(\overline{I_{1}}=\overline{\lambda_{1}^2}+\overline{\lambda_{2}^2}+\overline{\lambda_{3}^2}\) Первый инвариант деформации

\(\lambda_{i}\) \(i_{th}\) основное инженерное растяжение

Материал с LAW92 можно определить двумя способами:

Ввод параметров

Модуль сдвига, объемный модуль и растяжение при деформации (\(\mu,D,\lambda_{m})\)

Где только вышеуказанные 3 параметра с ясным физическим смыслом необходимы для определения материала.

\(\mu\) — это модуль сдвига при нулевой деформации.

\[D=\frac{2}{K} \tag{95}\]

Где,

\(K\) Коэффициент объемной деформации при нулевой деформации

\(\lambda_{m}\) Определяет предел растяжения

Axel Products, Inc. “Сжатие или двуосное расширение”, Ann Arbor, MI (2017). Последнее изменение 12 ноября 2008 г.

Kolling, S., P. A. Du Bois, D. J. Benson и W. W. Feng. “Табличная формулировка гиперэластичности с эффектами скорости и повреждениями”. Computational Mechanics 40, № 5 (2007): 885-899

- Также называется фиксирующим растяжением. Определяет начало фазы затвердевания при растяжении

(фиксирующая деформация при растяжении). По умолчанию = 7,0.

Рисунок 145:блокировка растяжения \(\lambda_{m}\)

При параметрическом вводе коэффициент Пуассона вычисляется как:

При использовании ввода функции необходимо определить коэффициент Пуассона и Itype. Itype определяет, какой тип данных испытания на деформацию при проектировании используется в качестве входных данных.

- width

2.93342in

- height

2.46679in

Рисунок 146: Itype = 1: одноосный тест данных .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image1-7.jpg

- width

2.73349in

- height

2.01675in

Рисунок 147: Itype = 2: Тест данных для эквибиаксиального сжатия

Рисунок 148: Itype = 3: Тест плоских данных

Коэффициент Пуассона и несжимаемость материала

Если входные данные функции определены, то параметры \(\mu,D,\lambda_{m}\) игнорируются, и PRADIOS вычислит постоянную материала, подгоняя входную функцию. Для подгонки параметров ArrudaBoyce PRADIOS использует нелинейный алгоритм наименьших квадратов. Подгонка кривой выполняется с использованием предположения, что значение Пуассона близко к 0,5, что означает, что материал несжимаем. Подобно другим моделям гиперупругих материалов, значения коэффициента Пуассона, близкие к 0,5, приводят к высокому модулю объемной упругости и меньшему временному шагу. Для хорошего баланса между несжимаемостью и разумным временным шагом рекомендуется значение коэффициента Пуассона 0,495.

Информацию о подгонке материалов можно найти в выходном файле Starter (*0000.out).

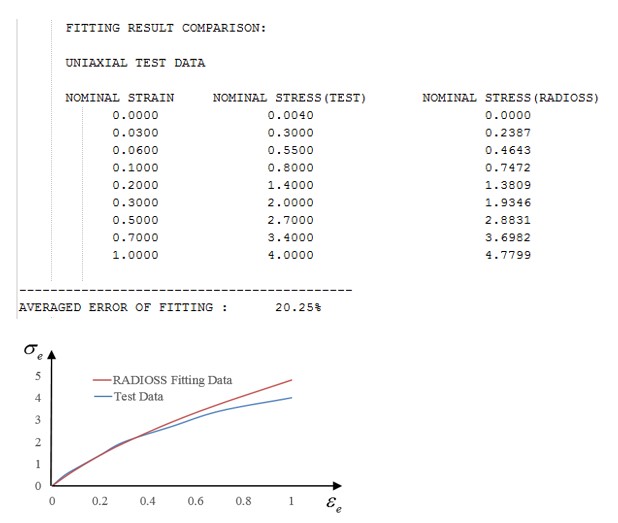

Рисунок 149: пример функции LAW92

Ошибка подгонки и параметры подогнанного материала печатаются в выходном файле Starter.

Рисунок 150:*

Вязкость (Эффекты скорости

/VISC/PRONY необходимо использовать с LAW92 для включения эффектов вязкости.

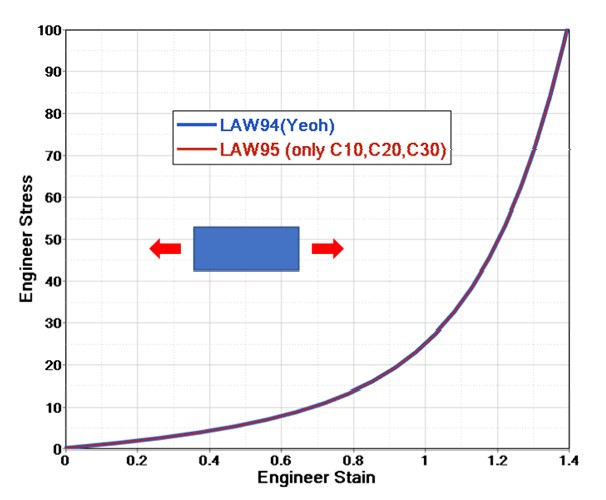

Йео (/MAT/LAW94)

LAW94 — это гиперупругая модель материала, которую можно использовать для описания несжимаемых материалов.

Функция плотности энергии деформации LAW94 зависит только от первого инварианта деформации и вычисляется как:

Где,

\(\overline{I_{1}}=\overline{\lambda_{1}^2}+\overline{\lambda_{2}^2}+\overline{\lambda_{3}^2}\) Первый инвариант деформации

\(\overline{\lambda_{i}}=J^{-\frac{1}{3}}\lambda_{i}\) Девиаторное растяжение

Напряжение Коши равно:

Параметры материала

Для несжимаемых материалов с =1 только и являются входными данными, а модель Йео сводится к модели НеоХука.

Arruda, E. M. и Boyce, M. C., 1993, «Трехмерная модель для поведения эластичных резиновых материалов при больших растяжениях», J. Mech. Phys. Solids, 41(2), стр. 389–412

\(C_{10}C_{20}C_{30}\) Константы материала определяют девиаторную часть (изменение формы) материала

\(D_{1,}D_{2,}D_{3}\) Параметры определяют объемное изменение материала

Эти шесть констант материала необходимо рассчитать с помощью подгонки кривой данные испытаний материала. RD-E: 5600

Гиперупругий материал с вводом кривой включает подгонку Йео Скрипт Compose для одноосных данных испытаний. Модель материала Йео была показана для моделирования всех моделей деформации, даже если подгонка кривой была получена с использованием только данных одноосных испытаний.

Начальный модуль сдвига и объемный модуль упругости:

и

Коэффициент Пуассона и несжимаемость материала

LAW94 доступен только как модель несжимаемого материала.

Если = D1 0, то рассматривается несжимаемый материал, где v = 0,495 D1 вычисляется как:

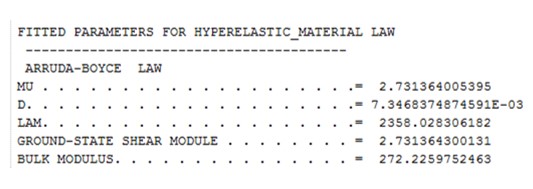

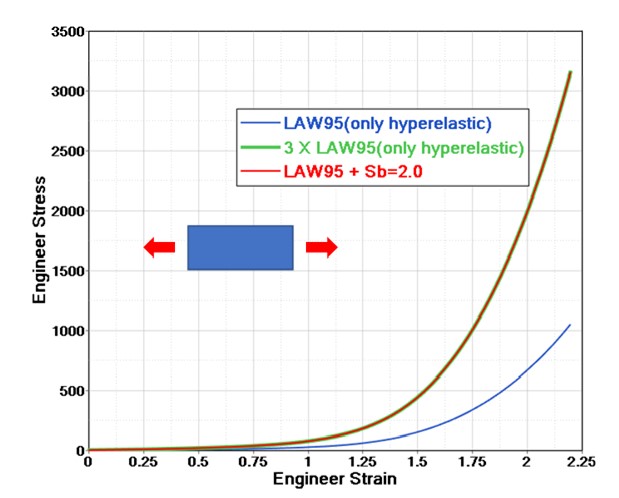

Бергстрем-Бойс (/MAT/LAW95)

Этот закон является конститутивной моделью для прогнозирования нелинейной зависимости от времени эластомерных материалов. Он использует полиномиальную модель материала для гиперупругого реакции материала и модель материала Бергстрема-Бойса для представления нелинейной вязкоупругой, зависящей от времени реакции материала.

Этот закон совместим только с твердыми элементами.

Реакция материала может быть представлена с помощью двух параллельных сетей A и B. Сеть A является равновесной сетью с нелинейным гиперупругим компонентом. В сети B нелинейный гиперупругий компонент находится последовательно с нелинейным вязкоупругим элементом потока, и, следовательно, является сетью, зависящей от времени.

10. Yeoh, O. H. “Некоторые формы функции энергии деформации для резины”. Rubber Chemistry and technology 66, № 5 (1993): 754-771 .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image2-1.png

- width

3.45667in

- height

3.48333in

Рисунок 151:

Параметры материала

Та же полиномиальная формулировка плотности энергии деформации используется для гиперупругих компонентов в обеих сетях. В сети B она масштабируется на коэффициент Sb. Затем плотность энергии деформации записывается для гиперупругого компонента сети.

и

Где,

\(\overline{I_{1}}=\overline{\lambda_{1}^2}+\overline{\lambda_{2}^2}+\overline{\lambda_{3}^2}\)

\(\overline{I_{2}}=\overline{\lambda_{1}^{-2}}+\overline{\lambda_{2}^{-2}}+\overline{\lambda_{3}^{-2}}\)

\(\overline{\lambda_{i}}=J^{-\frac{1}{3}}\lambda_{i}\)

\(C_{ij}\) и \(D_{i}\) Параметры материала

Гиперупругий компонент напряжения Коши вычисляется как:

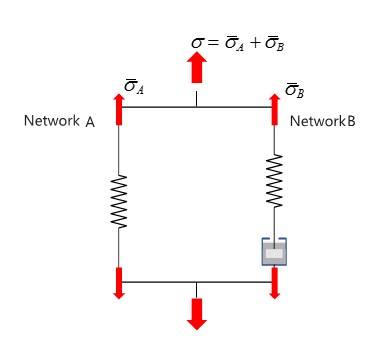

Общее напряжение — это сумма напряжений в сети A и сети B.

Рисунок 152:

\(\overline{\sigma}=\overline{\sigma_{A}}+\overline{\sigma_{B}}\)

Поскольку \(W_{B}=S_{b}\cdot W_{A}\), то \(\overline{\sigma}_{B}=S_{b}\cdot\overline{\sigma}_{A}\) и общее напряжение равно \(\sigma=(1+S_{b})\cdot\overline{\sigma}_{A}\)

Например, в одном испытании на растяжение. Если использовать Sb, то напряжение в 3 раза больше, чем без учета вязкости (что означает только учет гиперупругости).

Рисунок 153:

Для специальных значений полиномиальная модель может быть сведена к следующим материальным моделям.

Рисунок 154:

Mooney-Rivlin:

\(i+j=1\)

Где, \(C_{10}\) и \(C_{01}\) не равны нулю и \(D_{2}=D_{3}=0.\)

Neo-Hookean:

Только \(C_{10}\) и \(D_{1}\) не равны нулю.

Где,

\(C_{ij}\) и \(D_{i}\) Параметры материала, которые можно рассчитать, выполнив подгонку кривой для данных квазистатических испытаний материалов.

RD-E: 5600 Гиперупругий материал с вводом кривой, содержит пример подгонки кривой для моделей материалов Муни-Ривлина и Йео. можно рассчитать из объемного модуля или оставить пустым.

Начальный модуль сдвига и объемный модуль вычисляются как:

и

Если объемный модуль материала известен, можно рассчитать D1, или если D1 =0, предполагается несжимаемый материал.

Эффекты вязкости (скорости)

Эффективная скорость деформации ползучести в сети B определяется по формуле:

Где,

\(\overline{\dot{\lambda}}=\sqrt{\frac{T_{1}}{3}}\)

\(\overline{\sigma}_{B}\) Эффективное напряжение в сети B.

\(A, \bar{\varepsilon}, M, C\) , and \(\tau_{ref}\) Входные параметры материала. Константы материала A, M и C ограничены определенным диапазоном действительных значений, как определено в Справочном руководстве. Если доступны ограниченные данные, можно использовать метод проб и ошибок11 для определения этих констант. Начните со значений по умолчанию \(\bar{\xi}, M, C, S_{b}\) =1,6; и A=5. Затем сравните прогнозы модели с экспериментальными данными по крайней мере для одной скорости деформации и скорректируйте A, чтобы получить соответствие для данных скорости деформации.

Bergström, J. S., and M. C. Boyce. “Constitutive modeling of the large strain time-dependent behavior of elastomers.” Journal of the Mechanics and Physics of Solids 46, no. 5 (1998): 931-954

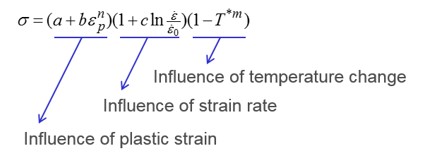

Эласто-пластичные материалы

Джонсон-Кук (/MAT/LAW2)

В LAW2 расчет напряжений состоит из трех частей.

Рисунок 155: - Влияние пластической деформации

Влияние скорости деформации

Влияние изменения температуры

Параметры материала

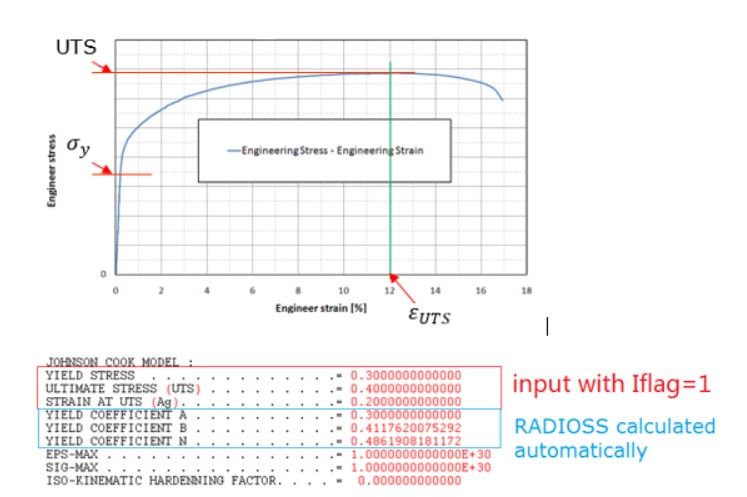

Существует два способа ввода параметра материала для LAW2.

Iflag=0: Классический ввод для параметра Джонсона-Кука a, b, n активен

Iflag=1: Новый, упрощенный ввод с пределом текучести, UTS (инженерное напряжение) или деформацией при UTS Iflag= 0

Где,

- a

Предел текучести, который можно определить по результатам испытания материала и преобразовать в истинное напряжение.

- b и n

Параметры материала. Подгонка кривой напряжения-деформации материала (например, скрипт Laduga Compose) может привести к этим двум параметрам.

- Iflag = 1

С этим новым вводом вам понадобится предел текучести, предел прочности на растяжение (UTS) и инженерная деформация в точке сужения. С этим новым вводом PRADIOS автоматически вычисляет эквивалентное значение для a, b и n.

Рисунок 156: Испытание на растяжение

Скорость деформации

Скорость деформации оказывает большое влияние на характер материала на характеристики удара при растяжении или при разрыве. В теории Джонсона-Кука предел текучести напрямую зависит от скорости деформации и описывается как:

Обычно предел текучести увеличивается с увеличением скорости деформации испытания. С коэффициентом скорости деформации c вы можете масштабировать фактор увеличения предела текучести. Никакого влияния скорости деформации также не может быть определено, если c =0; или с \(\xi_{0}=10^{30} или \xi\leq\xi_{0}).\) .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image27.jpg

- width

2.9836in

- height

3.0836in

Рисунок 157:

Изменение температуры

Предел текучести уменьшается с ростом температуры. В LAW2 влияние рассматривается с \(\left(1-T^{\*m}\right).\)

с

Где,

\(T_{melt}\) Температура расплава в единицах Кельвина.

\(T_{r}\) Температура в помещении в единицах Кельвина.

С T, вычисленным как:

Где,

\(E_{int}\) Внутренняя энергия.

Изменение внутренней энергии повлияет на предел текучести в законе Джонсона-Кука.

Коэффициент упрочнения

Металл деформируется до предела текучести, а затем в целом закаляется (предел текучести увеличивается). Разные материалы демонстрируют разные способы закалки (изотропная закалка, кинематическая закалка и т. д.). Это также очень важная характеристика материала (для упругого возврата).

В LAW2 используйте опцию \(C_{hard}\) (коэффициент закалки), чтобы описать, какая модель закалки используется для материала. Эта функция также доступна в материалах LAW36, 43, 44, 57, 60, 66, 73 и 74.

Значение \(C_{hard}\) составляет от 1 до 0. \(C_{hard}\) =0 для изотропной модели, \(C_{hard}\) =1 для кинематической модели Прагера-Циглера или между 1 и 0 для закалки между двумя указанными выше моделями.

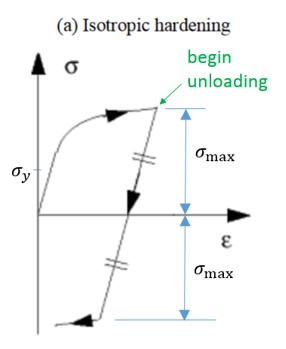

\(C_{hard}\) = 0: Изотропная модель

- В одномерном случае материал укрепляется после предела текучести.

Максимальное напряжение последнего растяжения является пределом текучести при последующей нагрузке, и этот новый предел текучести одинаков при последующих растяжении и сжатии.

Рисунок 158:

\(C_{hard}\) = 1: Кинематическая модель Прагера-Циглера

Для моделирования эффекта Баушингера (после упрочнения при растяжении происходит размягчение при последующем сжатии, что означает снижение текучести при сжатии) используйте кинематическое упрочнение.

Рисунок 159:

Упругий пластичный кусочно-линейный материал (/MAT/LAW36)

В LAW36 количество пластических кривых напряжения-деформации можно определить напрямую для различных скоростей деформации.

Пластическое напряжение-деформация высокой скорости деформации всегда должно быть выше нижней пластической кривой напряжения-деформации. .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image30.jpg

- width

8.05061in

- height

3.04185in

Рисунок 160:

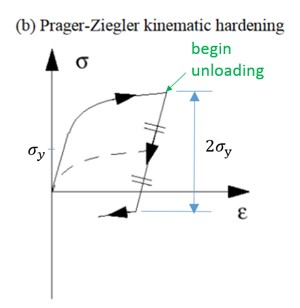

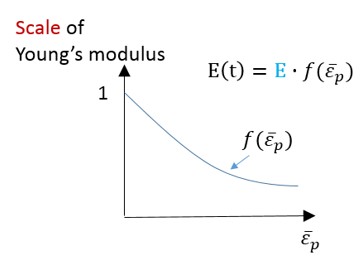

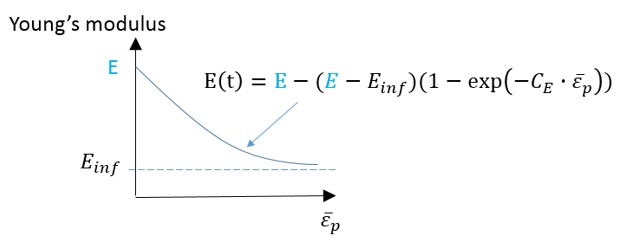

Модуль Юнга

Модуль Юнга можно обновить (уменьшить) при разгрузке с помощью опций fct_IDE, Einf и CE. Использование этой функции повышает точность пружинения (в фазе разгрузки) для высокопрочной стали. Эта функция также доступна в материалах LAW43, LAW57, LAW60, LAW74 и LAW78.

Используйте fct_IDE для обновления модуля Юнга (fct_IDE ≠ 0):

Рисунок 161:

Используйте Einf and CE обновить модуль Юнга (fct_IDE = 0):

Рисунок 162:

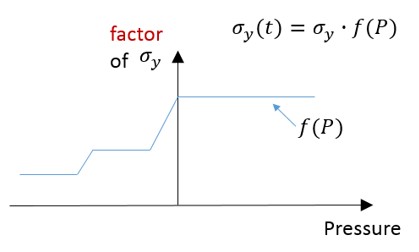

Поведение материала

fct_IDp используется для различения поведения при растяжении и сжатии для определенных материалов (текучесть, зависящая от давления). Затем эффективный предел текучести получается путем умножения номинального предела текучести на коэффициент текучести, соответствующий фактическому давлению.

Рисунок 163:

Материалы HILL

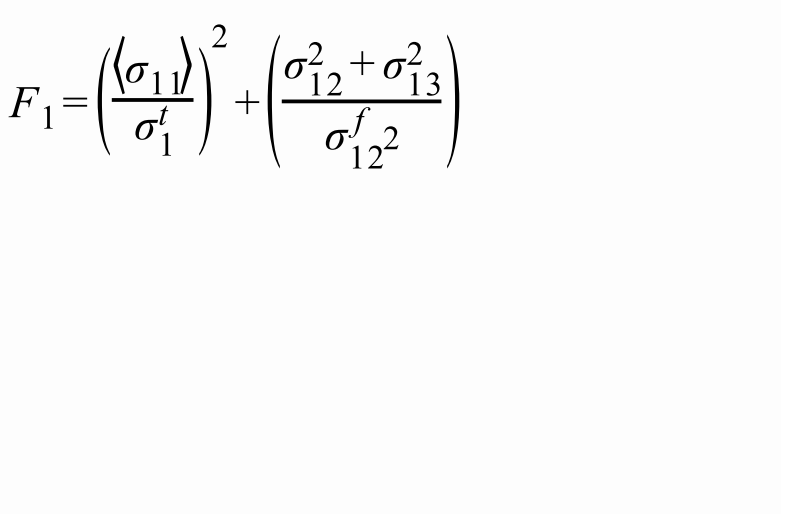

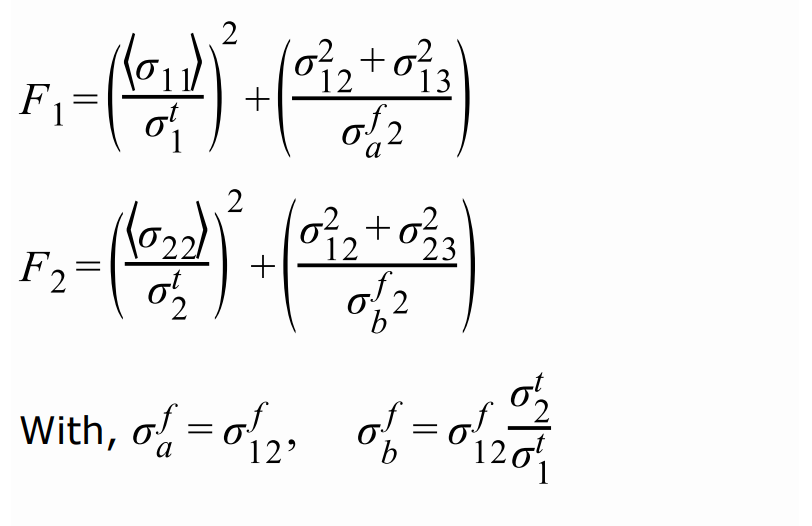

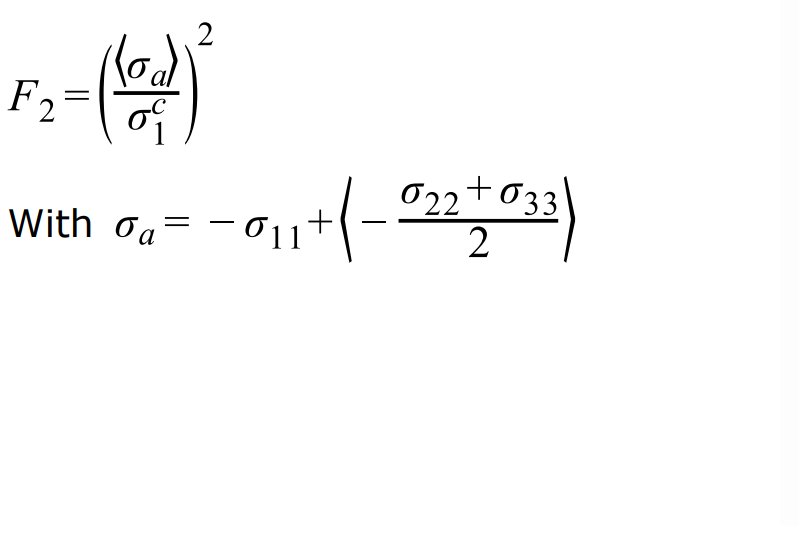

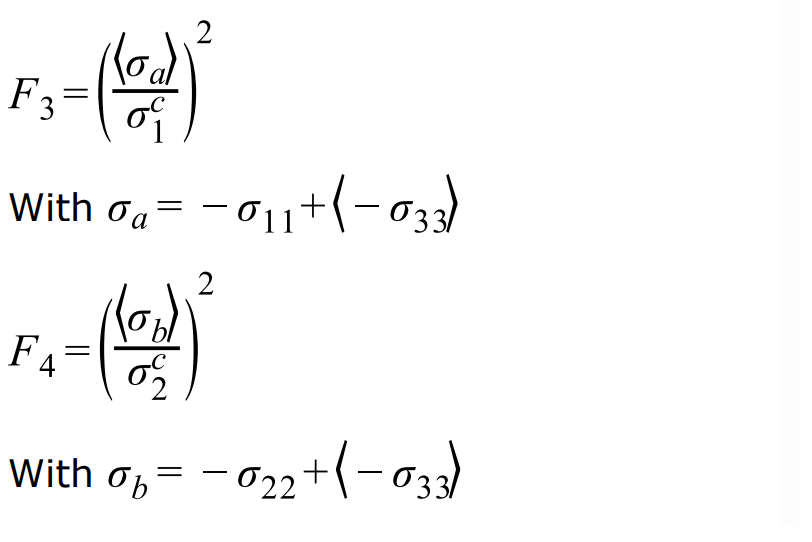

В законах о материалах PRADIOS LAW32, LAW43, LAW72, LAW73, LAW74, LAW78 и LAW93 используются критерии HILL.

Критерии ХИЛЛА

Типичные критерии ХИЛЛА:

3D эквивалентное напряжение ХИЛЛА:

Элемент оболочки:

Где F, G, H, L, M и N — шесть анизотропных ХИЛЛ параметры. Для элементов оболочки только F, G, H и N являются четырьмя необходимыми параметрами HILL.

В LAW78 критерии HILL следующие:

Существует два способа определения параметров HILL с использованием параметров Лэнкфорда.

◦ Коэффициент деформации \(r_{00}, r_{45}, r_{90}\) (LAW32, LAW43, LAW72, LAW73)

◦ Коэффициент текучести \(R_{1}, R_{22}, R_{33}, R_{12}, R_{13}, R_{23}\) (LAW74, LAW93)

Коэффициент деформации

Параметры Ланкфорда \(r_{\alpha}\) — это отношение пластической деформации в плоскости и пластической деформации в направлении толщины \(\varepsilon_{33}\).

Где, \(\alpha\) — угол к ортотропному направлению 1.

\(r_{\alpha}\) можно измерить с помощью разных образцов, которые разрезаны под разным углом к ортотропному направлению 1. Например, \(r_{00}\) измерено при испытании на растяжение, в котором направление нагрузки вдоль ортотропного направления 1. \(r_{90}\) измерено при испытании на растяжение, в котором нагрузка перпендикулярна ортотропному направлению 1.

Отношение деформации — это деформация в направлении ширины образца к деформации в направлении толщины образца. .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image3-5.jpg

- width

4.9921in

- height

2.32521in

Рисунок 164: В этом случае параметры HILL следующие:

Здесь *G+H*=1.

В LAW32, LAW43 и LAW73 критерии HILL следующие:

\(R=\frac{r_{00}+2r_{4.5}+r_{90}}{4}\) \(H=\frac{R}{1+R}\)

\(A _{1}=H\Big{(}1+\frac{1}{r_{00}}\Big{)}\) \(A_{2}=H\Big{(}1+\frac{1}{r_{90}}\Big{)}\)

\(A_{3}=2H\) \(A_{12}=2H(r_{4.5}+0.5)\Big{(}\frac{1}{r_{00}}+\frac{1}{r_{90}}\Big{)}\)

Все они запрашивают параметр Ланкфорда (коэффициент деформации) \(r_{00}, r_{4.5}, r_{90}\) и параметр HILL \(A_{i}\) автоматически вычисляется PRADIOS.

Коэффициент текучести

В LAW93 используется отношение предела текучести:

Чтобы получить отношение предела текучести \(R_{ij}\), необходимо измерить предел текучести в двух случаях нагрузки.

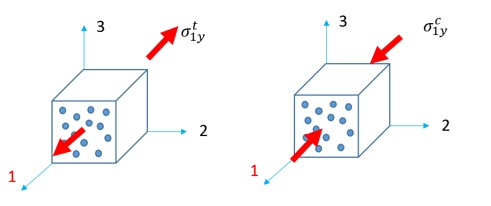

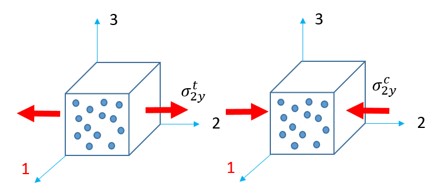

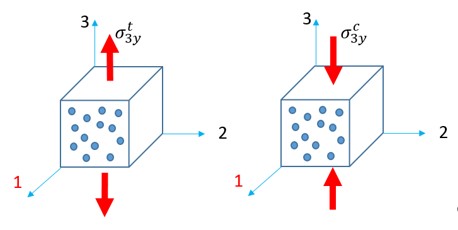

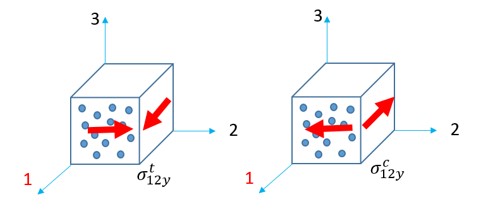

Предел текучести \(\sigma_{11,}\sigma_{22,}\sigma_{33}\) из испытания на растяжение

Предел текучести при сдвиге \(\sigma_{12,}\sigma_{13,}\sigma_{23}\) из испытания на сдвиг

В LAW93, если используется ввод параметров, то возьмите начальный параметр напряжения \(\sigma_{y}\) в качестве опорного предела текучести \(\sigma_{0}\). Если используется входная кривая, то возьмите предел текучести из кривой в качестве опорного предела текучести \(\sigma_{0}\).

Четыре параметра HILL для оболочки автоматически вычисляются PRADIOS.

В LAW74 коэффициент текучести \(R_{ij}\) используется с пределом текучести \(\sigma_{11,}\sigma_{22,}\sigma_{33,}\) и \(\sigma_{12,}\sigma_{13}\sigma_{23}\) вводимыми напрямую, а затем шесть параметров HILL для твердого тела автоматически вычисляются PRADIOS.

\(F=\frac{1}{2}\Bigg{(}\frac{1}{\sigma_{22}^{2}}+\frac{1}{\sigma_{33}^{2}}-\frac{1}{\sigma_{11}^{2}}\Bigg{)}\) \(G=\frac{1}{2}\Bigg{(}\frac{1}{\sigma_{22}^{2}}+\frac{1}{\sigma_{33}^{2}}-\frac{1}{\sigma_{11}^{2}}\Bigg{)}\)

\(H=\frac{1}{2}\Bigg{(}\frac{1}{\sigma_{22}^{2}}+\frac{1}{\sigma_{33}^{2}}-\frac{1}{\sigma_{11}^{2}}\Bigg{)}\) \(L=\frac{1}{2\sigma_{23}^{2}}\)

\(M=\frac{1}{2\sigma_{31}^{2}}\) \(N=\frac{1}{2\sigma_{12}^{2}}\)

Для элемента оболочки возьмите M=N и L=N.

Бетон и скальные материалы

В PRADIOS эти материалы могут использоваться для представления скальных или бетонных материалов.

Эти материалы используют критерий текучести Дрюкера–Прагера12, который представляет собой модель, зависящую от давления, для определения того, разрушился ли материал или подвергся пластической деформации.

Бетонный материал (/MAT/LAW10 и /MAT/LAW21)

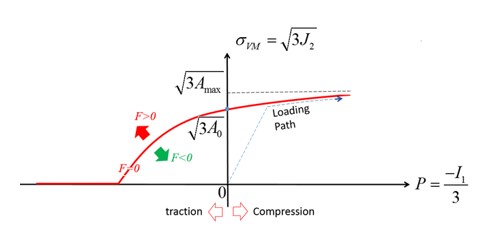

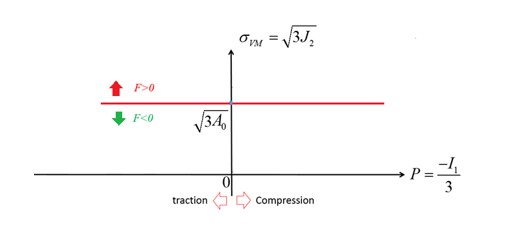

Критерии доходности Дрюкера-Прагера

Материал разрушился или подвергся пластической деформации, определяется давлением с использованием:

Где,

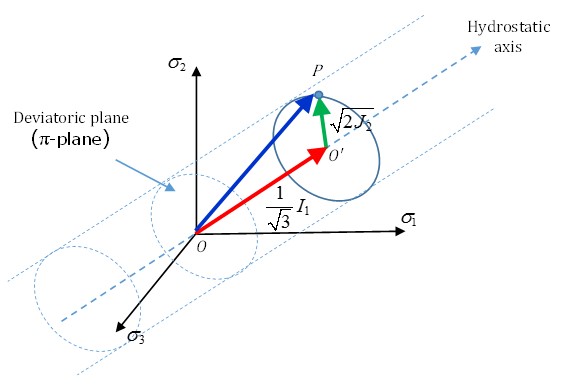

\(J_{2}\) Второй инвариант напряжения (напряжение по Мизесу) девиаторной части напряжения и \(P=-\frac{I_{1}}{3}\).

\(I_{1}\) Первый инвариант напряжения (гидростатическое давление).

\(I_{1}=\sigma_{1}+\sigma_{2}+\sigma_{3}=-3P\)

\(J_{2}=\frac{1}{6}\bigg{[}\big{(}\sigma_{1}-\sigma_{2}\big{)}^{2}+\big{(}\sigma_{2}-\sigma_{3}\big{)}^{2}+\big{(}\sigma_{3}-\sigma_{1}\big{)}^{2}\bigg{]}=\frac{1}{3}{\sigma_{VM}2}\) при одноосном испытании.

Рисунок 165: Критерии текучести Дрюкера-Прагера

Для описания давления \(A_{0}+A_{1}P+A_{2}P^{2}\) на поверхности текучести Дрюкера-Прагера материала используется полиномиальное уравнение: .. math:: sigma_{VM}=sqrt{3big{(}A_{0}+A_{1}P+A_{2}P^{2}big{)}} tag{128}

Константы полинома \(A_{0}, A_{1}, A_{2}\) определяются по формуле:

Если \(F<0, J_{2}<A_{0}+A_{1}P+A_{2}P^{2}\) материал находится под поверхностью текучести и в упругой области.

Если \(F=0, J_{2}=A_{0}+A_{1}P+A_{2}P^{2}\) и материал находится на поверхности текучести.

Если \(F>0, J_{2}>A_{0}+A_{1}P+A_{2}P^{2}\) и материал вышел за пределы поверхности текучести и разрушился.

Если \(A_{1}=A_{2}=0,\sigma_{VM}=\sqrt{3J_{2}}=\sqrt{3A_{0}}\), что является критерием фон Мизеса.

Рисунок 166:

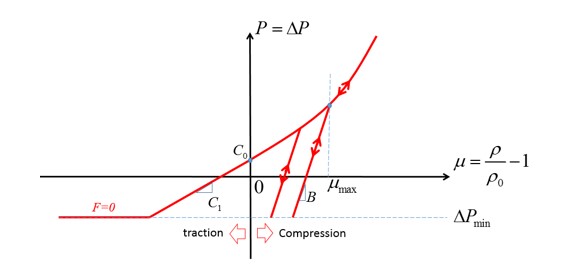

Вычисление давления

В LAW10 для описания давления используется полиномиальное уравнение с входными параметрами \(C_{0}C_{1}C_{2}C_{3}\) . Давление можно построить как функцию объемной деформации.

Если \(P_{ext}=0\), давление равно \(P=\Delta P\), а предел давления равен \(P_{\min}=\Delta P_{\min}\).

- width

4.72542in

- height

2.30019in

Рисунок 167: Кривая давления без внешнего давления

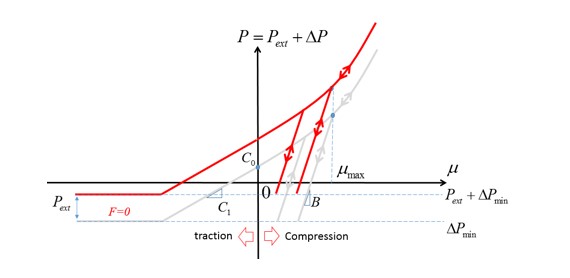

Если \(P_{ext}\neq 0\), давление смещается на \(P_{ext}, тогда P=P_{ext}+\Delta P\) и предел давления равен \(P_{\min}=P_{ext}+\Delta P_{\min}\).

- width

4.75042in

- height

2.31686in

Рисунок 168: Кривая давления с внешним давлением

Здесь,

При растяжении или натяжении давление линейно и ограничено \(\Delta P_{\min}\).

При сжатии давление нелинейно и также ограничено \(\Delta P_{\min}\).

Единственное различие между материальными законами заключается в том, что в LAW10 материальные константы \(C_{0} C_{0} C_{2} C_{3}\) используются для описания давления в зависимости от объемной деформации (кривая \(P-\mu\)). В LAW21 вы можете описать эту кривую с помощью ввода функции fct_IDr.

Загрузка и разгрузка

В LAW10 и LAW21 различные пути нагрузки и разгрузки кривой \(P-\mu\) можно рассматривать с использованием параметров \(\mu_{\max}\) и B.

В напряжении (\(\mu<0)\)

Для LAW10 линейная загрузка и выгрузка с \(P=C_{1}\mu\) (рисунок 167).

Для LAW21 загрузка определяется с помощью входной функции fct_IDr и линейной разгрузки с помощью:math:P=K_{1}mu.

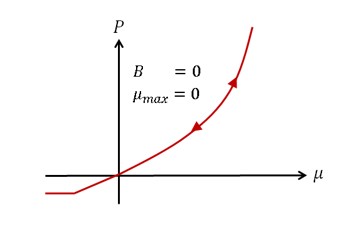

В режиме сжатия \(\mu > 0\), for both LAW10 and LAW21:

Если не определены ни B, ни \(\mu_{\max}\), то пути загрузки и выгрузки идентичны.

Рисунок 169: Идентичная загрузка и выгрузка для LAW10 и LAW21

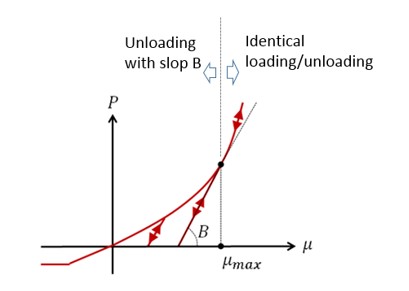

Если определено либо B, либо \(\mu_{\max}\):

Если определено только B, \(\mu_{\max}\) — это объемная деформация, где касательная к кривой \(P-\mu\) равна B с:math:B=frac{dP}{dmu}Big{|}_{mu_{max}}.

Если определено только \(\mu_{\max}\), то B является касательной к кривой \(P-\mu\) в \(\mu_{\max}\). Нагрузка и разгрузка при сжатии:

Если \(\mu>\mu_{\max}\), Путь загрузки и разгрузки идентичен.

Если \(\mu<\mu_{\max}\), Пути загрузки и разгрузки различны, это линейная разгрузка с уклоном B.

Рисунок 170: Различная обработка нагрузки и разгрузки для LAW10 и LAW21

Бетонный материал (/MAT/LAW24)

LAW24 использует критерии Дрюкера-Прагера с ограничением текучести или без него для моделирования армированного бетонного материала. Этот закон материала предполагает, что два механизма разрушения бетонного материала — это растрескивание при растяжении и сжатие.

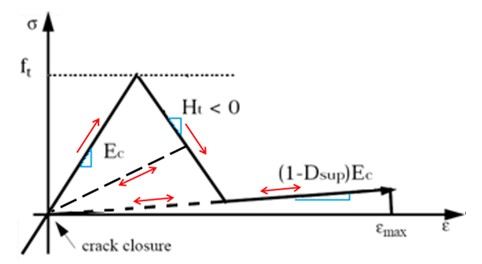

Поведение бетона при растяжении

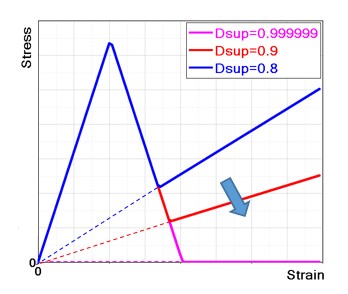

В LAW24 параметры \(H_{t}, D_{sup}\) и \(\varepsilon_{\max}\) могут использоваться для описания растрескивания при растяжении и разрушения при растяжении.

Рисунок 171: Растягивающая нагрузка LAW24

В начальной очень малой упругой фазе материал имеет модуль упругости \(E_{c}\).

После достижения предела прочности на растяжение \(f_{t}\) бетон начинает размягчаться с наклоном \(H_{t}\). Максимальный коэффициент повреждения \(D_{sup}\) имеет значение, поскольку он позволяет моделировать остаточную жесткость во время и после трещины.

Рисунок 172: Максимальные эффекты фактора повреждения

Остаточная жесткость вычисляется как:

Когда происходит закрытие трещины, бетон снова становится эластичным, и фактор повреждения (для каждого направления) сохраняется.

Несущая способность бетона при растяжении намного ниже, чем при сжатии. Обычно он считается эластичным при растяжении.

Рекомендуется выбирать значение \(D_{sup}\) близкое к 1 (по умолчанию 0,99999), чтобы минимизировать текущую жесткость в конце повреждения и, следовательно, избежать остаточного напряжения при растяжении, которое может стать очень высоким, если элемент сильно деформирован из-за растяжения. Это произойдет, если сила, вызывающая повреждение, останется.

Можно настроить \(D_{sup} (и H_{t})\), чтобы смоделировать и подогнать поведение бетона, армированного волокнами. Бетонный материал разрушается, как только достигает полной деформации разрушения \(\varepsilon_{\max}\).

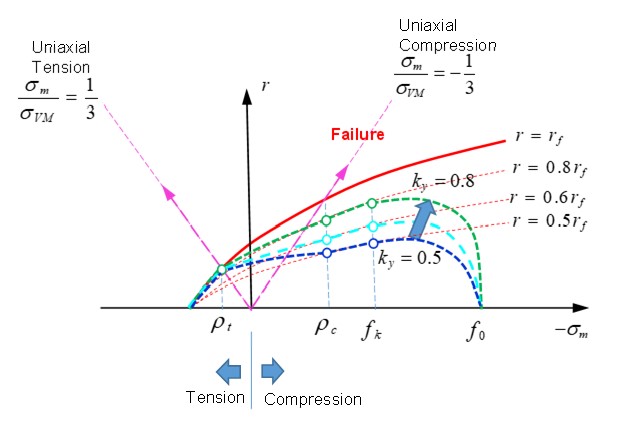

Поверхность текучести бетона при сжатии

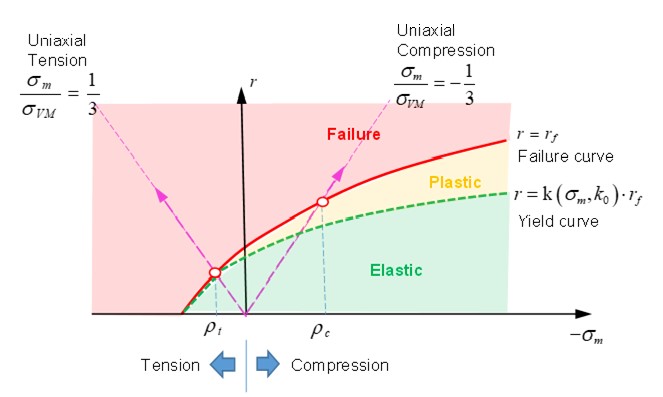

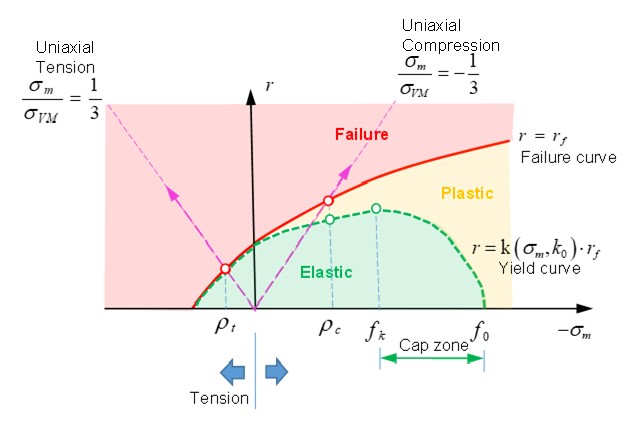

Для бетона поверхность текучести является началом зоны пластического упрочнения, которая находится между поверхностью разрушения, \(r_{f}\), и поверхностью текучести.

Поверхность текучести предполагается такой же, как поверхность разрушения в зоне растяжения. При сжатии поверхность текучести представляет собой уменьшенную поверхность разрушения с использованием коэффициента k(\(\left(\sigma_{m},k_{0}\right))\). Выход в LAW24 для бетона:

Для \(I_{cap}\) =0 или 1 (без ограничения выхода) кривая выхода:

- width

5.52549in

- height

3.30863in

Рисунок 173: Критерии Дрюкера-Прагера без ограничения выхода

Для \(I_{cap}\) =2 (с пределом текучести) выход равен:

- width

5.24213in

- height

3.52531in

Рисунок 174: Критерии Дрюкера-Прагера с пределом текучести

\(r<k\big{(}\sigma_{m},k_{0}\big{)}\cdot r_{f}\) (зеленая область на рисунке 174)

Материал находится под пределом текучести в упругой фазе.

\(r\geq r_{f}\) (красная область на рисунке 174)

Материал не выдержал испытания.

\(k\big{(}\sigma_{m},k_{0}\big{)}\cdot r_{f}<r<r_{f}\) (желтая область на рисунке 174)

Материал находится выше предела текучести и ниже поверхности разрушения, которая представляет собой фазу пластического упрочнения.

Входной параметр \(\rho_{t}\) — это гидростатическое давление разрушения при одноосном испытании на растяжение, а \(\rho_{c}\) — это гидростатическое давление при разрушении при одноосном испытании на сжатие.

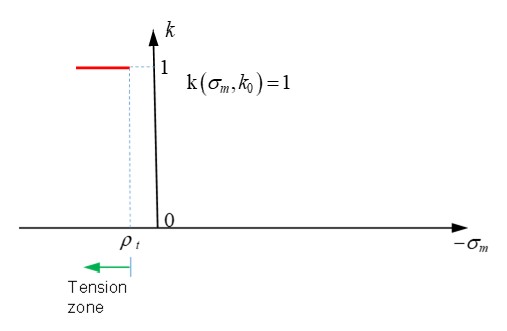

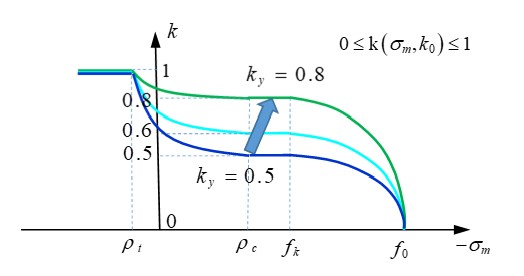

Масштабный коэффициент \(k\big{(}\sigma_{m},k_{0}\big{)}\) является функцией среднего напряжения \(\sigma_{m}\) и может быть описан как:

- Когда

\(\sigma_{m}\geq\rho_{t}\) (при растяжении) масштабный коэффициент \(k\big{(}\sigma_{m},k_{0}\big{)}=1)\). В этом случае поверхность текучести равна поверхности разрушения, \(r=r_{f}\).

Рисунок 175: k-функция в зоне растяжения

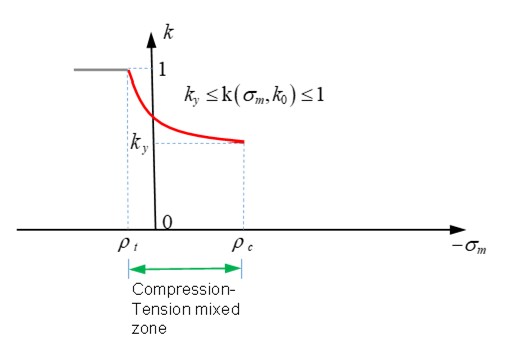

В области растяжения-сжатия, \(\rho_{t}>\sigma_{m}\geq\rho_{c,}\) затем

\(\mathrm{k}\big{(}\sigma_{m} k_{0}\big{)}=1+\frac{\big{(}1-k_{0}\big{)}\cdot\Big{[}\rho_{t}\big{(}2\rho_{c}-\rho_{t}\big{)}-2\rho_{c}\sigma_{m}+\sigma_{m}\Big{]}}{\big{(}\rho_{c}-\rho_{t}\big{)}^{2}} \mathrm{with} k_{y}\leq k_{0}\leq 1\)

Рисунок 176: функция k в зоне сжатия-растяжения

- Остальная часть кривой зависит от опции \(I_{cap}\) и различных используемых масштабных коэффициентов \(k\big{(}\sigma_{m},k_{0}\big{)}\).

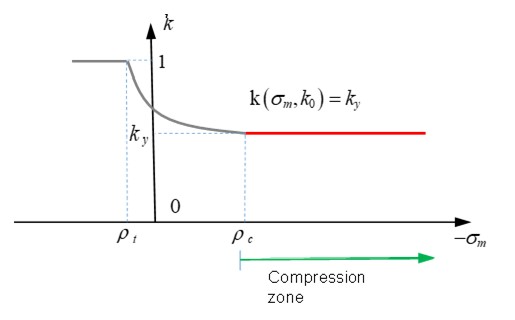

◦ Для \(I_{cap}\) =0 or 1 and \(\sigma_{m}<\rho_{c}\) (при сжатии), то \(k\big{(}\sigma_{m},k_{0}\big{)}=k_{y}\)

Рисунок 177: Функция K в зоне сжатия

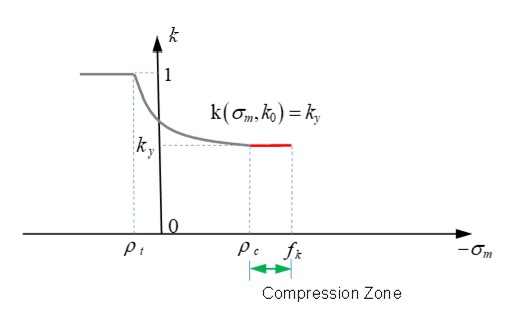

◦ Для \(I_{cap}\) =2 (с пределом доходности) и \(\rho_{c}<\sigma_{m}<f_{k}\) (при сжатии), то \(k\big{(}\sigma_{m},k_{0}\big{)}=k_{y}\)

Рисунок 178: Функция K в критериях Дрюкера-Прагера без ограничения

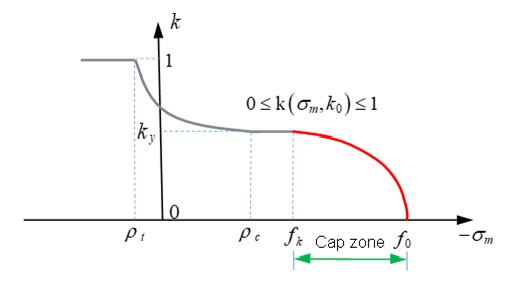

◦ В \(f_{k}<\sigma_{m}<f_{0}\) (в кеп-зоне)

\(\mathrm{k}\big{(}\sigma_{m},k_{0}\big{)}=k_{0}\bigg{[}1-\bigg{(}\frac{\sigma_{m}-f_{k}}{f_{0}-f_{k}}\bigg{)}^{2}\bigg{]},\mathrm{with} 0\leq k_{0}\leq k_{y}\)

Рисунок 179: Функция K в критериях Дрюкера-Прагера без ограничения

Константа материала \(k_{y}\) должна быть \(0\leq k_{y}\leq 1\). Более высокое значение \(k_{y}\) приводит к более высокой поверхности текучести. Например, если \(I_{cap}=2\) (текучесть с ограничением), разница в поверхности текучести между \(k_{y}=0,8\) и \(k_{y}=0,6\) (Рисунок 180). Значение по умолчанию \(k_{y}\) в LAW24 равно 0,5.

Рисунок 180: После различных значений функции K

Рисунок 181: Критерии Дрюкера-Прагера с различными значениями функции K

Правило пластического течения бетона при сжатии

В LAW24 используется неассоциированное правило пластического течения. Правило пластического течения:

Где,

\(\alpha\) Пластическая дилатансия.

\(\alpha=\frac{\partial g}{\partial I_{1}}\) Управляет объемным пластическим течением.

\(I_{1}\) Первый инвариант напряжения (гидростатическое давление).

Экспериментально \(\alpha\) является линейной функцией \(k_{0}\):

Если\(k_{0}=K_{y}\) то, \(\alpha=\alpha_{y}\) что означает, что материал находится в состоянии текучести.

Если\(k_{0}<K_{y}\) тогда, \(\alpha\) становится отрицательным, это область крышки.

Если\(k_{0}=1\) тогда, \(\alpha=\alpha_{f}\) что означает, что материал разрушился. Значения \(\alpha_{y}, \alpha_{f}\) используются для описания материала за пределами текучести, но до разрушения. Рекомендуется использовать -0,2 и -0,1 для \(\alpha_{y}, \alpha_{f}\) в LAW24. Если используются очень малые значения \(\alpha_{y}, \alpha_{f}\), то объемная пластичность отсутствует (область крышки отсутствует).

Разрушение бетона при сжатии

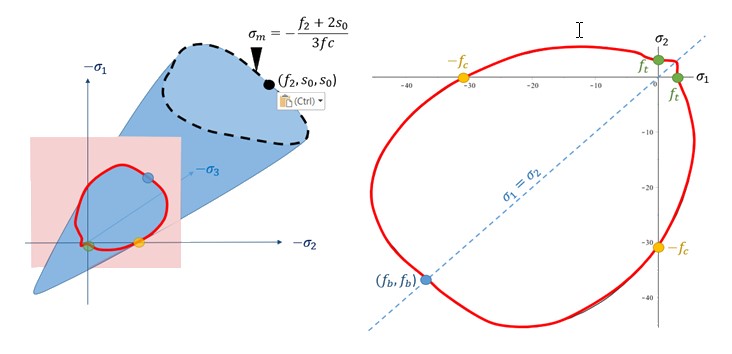

Поверхность разрушения определяется по формуле:

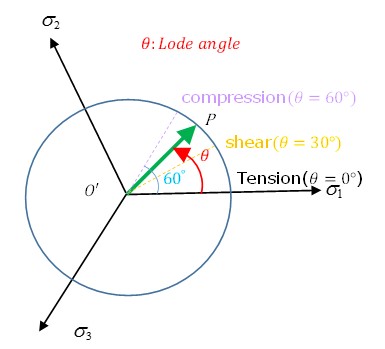

Где, \(r=\sqrt{2J_{2}}\left/\int_{c}\sigma_{m}=I_{1}\right/3f_{c}\). и \(\тета\) — угол Лоде, например:

Поверхность Оттозена строится для проектирования этой поверхности с использованием:

Где, \(a, b_{c}, b_{i} и c\) — это 4 значения, которые формируют поверхность и

Для бетона сжатие Кривая разрушения \(r_{f}\) может быть определена с прочностью:

\(f_{t}\) Одноосное растяжение (триаксиальность составляет 1/3)

\(f_{c}\) Одноосное сжатие (триаксиальность составляет -1/3)

\(f_{b}\) Двуосное сжатие (триаксиальность составляет -2/3)

\(f_{2}\) Прочность на ограниченное сжатие (трехосное испытание)

\(s_{0}\) Под ограниченным давлением Лучший способ полностью определить трехмерную область разрушения — получить экспериментальные данные для всех этих значений, \(f_{c} f_{f} f_{b} f_{2} s_{0}\), которые схематически проиллюстрированы на рисунке 182. .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image5-3.jpg

- width

5.80883in

- height

3.55031in

Рисунок 182: Параметры отказа, которые полностью определяют трехмерную огибающую отказа

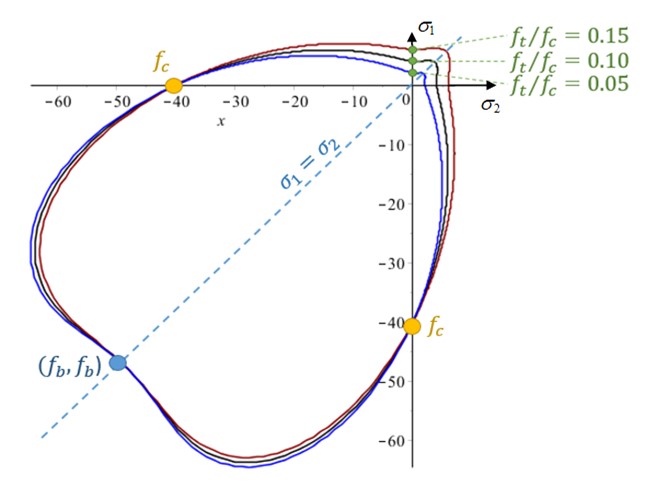

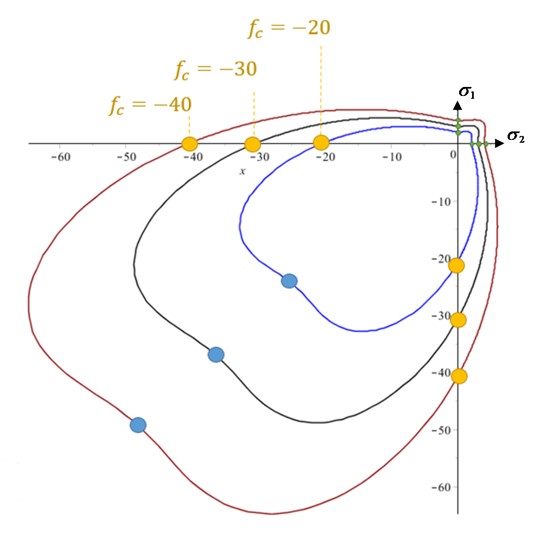

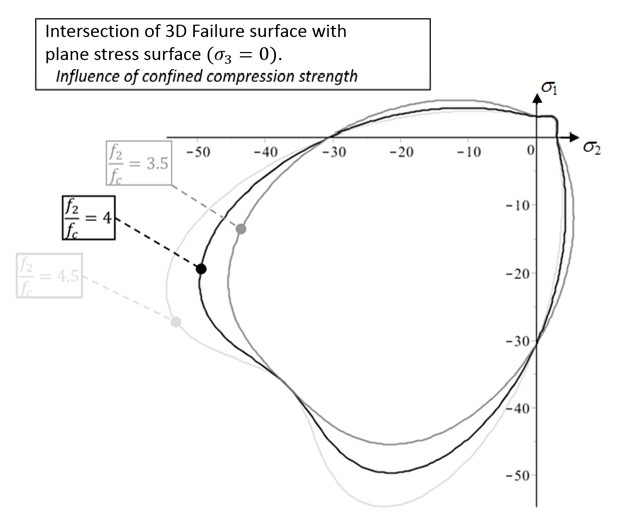

Рисунок 183 и Рисунок 184 показывают точки, которые определяют поверхность отказа.

Рисунок 183: След поверхности разрушения с плоской плоскостью напряжения .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/i-mage55.jpg

- width

6.09219in

- height

2.9836in

Рисунок 184: Траектория разрушения с несколькими планами разреза, которые перпендикулярны гидростатической оси

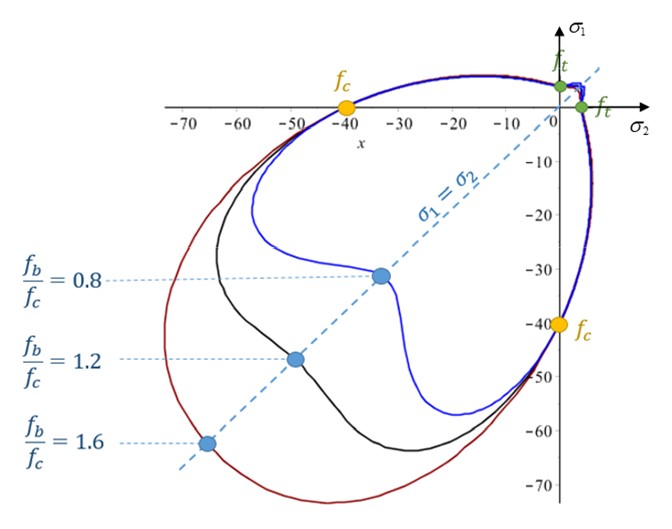

Из этих графиков следует, что область разрушения не является выпуклой поверхностью. Рисунок 185 показывает это поведение.

Рисунок 185: Влияние значения прочности на двухосное сжатие при всех других фиксированных характерных точках разрушения .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image5-7.jpg

- width

4.95043in

- height

4.80042in

Рисунок 186: Влияние значения прочности на сжатие при всех других фиксированных характерных точках разрушения

Рисунок 187: Влияние значения прочности на растяжение при всех других фиксированных характерных точках разрушения

В этом конкретном случае прочность на сжатие меняется, но все остальные соотношения фиксированы

. Это приводит к масштабированию огибающей, как показано на рисунке 188.

Рисунок 188: Влияние значения прочности на сжатие

Все остальные соотношения фиксированы.

Здесь с той же прочностью в LAW24, но с другой прочностью на ограниченное сжатие \(f_{2}\)

Рисунок 189: Огибающая разрушения на поверхности плоского напряжения, на которую влияет точка трехосного разрушения

\(\left(\sigma_{1,}\sigma_{2,}\sigma_{3}\right)=\left(f_{2,}s_{0,}s_{0}\right)\)

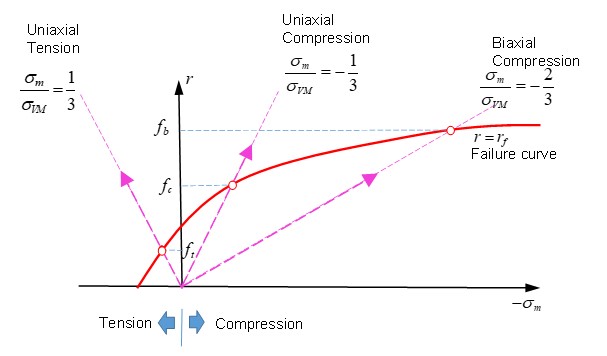

\(f_{c}\) и соотношения \(f_{t}/f_{c}\) и \(f_{b}/f_{c}\) in the :math:`r-sigma_{m} пространство (используемое для определения разрушения бетона):

Рисунок 190: Различные испытания (одноосное растяжение, одноосное сжатие и двухосное сжатие) для определения кривой разрушения

Если кривая разрушения определяется с помощью \(r=\sqrt{2J_{2}}=\sqrt{\frac{2}{3}} \sigma_{YM}\) и \(\sigma_{m}=\frac{I_{1}}{3}\) — среднее напряжение (давление), то \(I_{1}\) и \(J_{2}\) — первый и второй инварианты напряжения.

Материал разрушается, как только достигает кривой разрушения \(r_{f}\).

Армирование бетона

В PRADIOS есть два разных способа моделирования арматуры в бетоне.

Один способ - использовать балочные или ферменные элементы и соединить их с бетоном с помощью кинематических условий.

Другой способ - использовать параметры в LAW24 вместе с ортотропным свойством твердого тела

/PROP/ TYPE6для определения направления армирования. Параметры \(a_{1}, a_{2}, a_{3}\) в LAW24 используются для определения отношения площади поперечного сечения арматуры ко всей площади сечения бетона в направлении 1, 2, 3.

Где, \(\sigma_{y}\) - предел текучести арматуры. Если в качестве арматуры используется сталь, то \(\sigma_{y}\) — предел текучести стали, а \(E_{t}\) — модуль упругости стали в пластической фазе. .. image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image6-2.jpg

- width

3.30863in

- height

2.14185in

Рисунок 191: Кривая напряжения-деформации арматуры (сталь)

Бетонный материал (/MAT/LAW81)

LAW81 можно использовать для моделирования материалов из камня или бетона.

Критерии текучести Дрюкера-Прагера

LAW81 использует критерий текучести Дрюкера-Прагера, где поверхность текучести и поверхность разрушения одинаковы. Критерий текучести: .. math:: F=frac{q}{J_{2},text{part}}-frac{text{r}_{c}(p)cdotbig{(}text{ptan}phi+cbig{)}}{I_{1},text{part}}=0 tag{140}

Где,

\(q\) Стресс фон Мизеса с \(q=\sigma_{VM}=\sqrt{3J_{2}}\)

\(p\) Давление определяется как \(p=\frac{1}{3}I_{1}\)

Han, D. J., и Вай-Фа Чен. “Модель пластичности неравномерного упрочнения для бетонных материалов.” Механика материалов 4, no. 3-4 (1985): 283-302

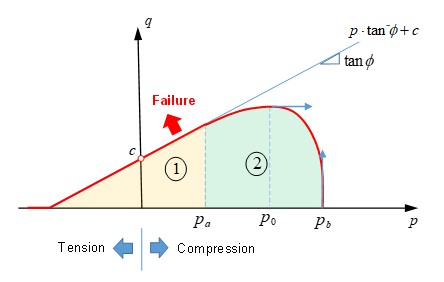

Рисунок 192: Поверхность текучести (LAW81)

Поверхность текучести можно описать двумя частями:

Линейная часть

(\(p\leq p_{a})\), где масштабная функция равна \(\mathrm{r}_{c}(p)=1\), что приводит к тому, что напряжение по Мизесу линейно пропорционально давлению:

Где,

\(c\) Когезионный и является точкой пересечения огибающей текучести с пределом прочности на сдвиг.

Если \(c\) =0, материал не имеет прочности при растяжении.

\(\phi\) Угол внутреннего трения, который определяет наклон огибающей текучести.

\(c\) и \(\phi\) также используются для определения поверхности текучести Мора-Кулона. Поверхность текучести Дрюкера-Праге является гладкой версией поверхности текучести Мора-Кулона.

Вторая часть

(\(p_{a}<p<p_{b})\) поверхности текучести имитирует предел текучести. Увеличение давления в камне или бетонном материале увеличит текучесть материала; но если давление увеличится достаточно, то камень или бетонный материал будет раздавлен. Модель Дрюкера-Прагера с пределом текучести может быть использована для моделирования этого поведения. Предел текучести определен в части

и использует функцию масштабирования:

Напряжение фон Мизеса равно:

Где,

\(P_{b}\) Кривая определяется с использованием входных данных \(fct_ID_{Pb}\)

\(p_{a}\) Рассчитано PRADIOS с использованием входного значения отношения \(a\).

\(p_{a}=\alpha\cdot P_{b}\) с \(0<\alpha <1\).

Где, \(P_{0}\) — максимальная точка кривой текучести, где \(\frac{\partial F}{\partial p}\left(p_{0}\right)=0\)

Если \(p=p_{b}\), то \(r_{\text{c}}\left(p_{b}\right)=0\) и функция текучести тогда,

\(q=0:\cdot\left(p\text{tan}\phi+c\right)=0\) что означает, что материал раздроблен.

Входные параметры \(\phi, c, p_{b^{\prime}}\alpha\) необходимо определить для поверхности текучести Друкера-Прагера. Для соответствия этим параметрам необходимо провести не менее четырех испытаний. В простейшем случае одноосное растяжение и одноосное сжатие можно использовать для определения линейной части, \(\phi, \text{и} c\). Для определения \(p_{b^{\prime}\) и \(\alpha\) необходимы двухосные испытания на сжатие и испытания на сжатие/сжатие (см. CC00 и CC01 в RD-E: 4701 Проверка бетона с помощью испытаний Купфера).

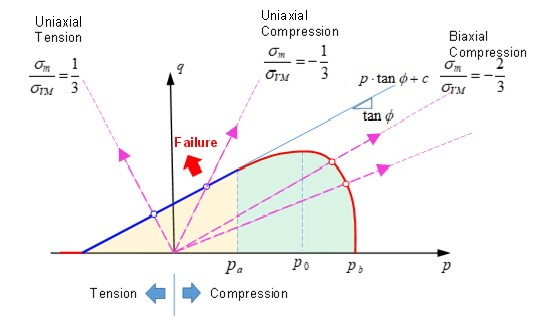

Рисунок 193: Поверхность текучести LAW81, показывающая различные условия нагрузки

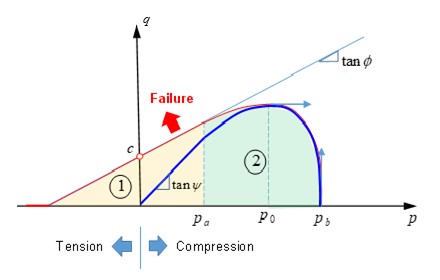

Для большинства материалов, таких как металл, приращение пластической деформации можно считать нормальным к поверхности текучести. Однако, если приращение пластической деформации нормально к поверхности текучести используется для материалов из камня или бетона, расширение пластического объема переоценивается. Поэтому в этих материалах используется неассоциированное правило пластического течения. В LAW81 функция пластического течения G определяется как:

\(G=q-p\cdot\tan\psi=0 if p\leq p_{a}\)

\(G=q-\tan\psi\left(p-\frac{\left(p-p_{a}\right)^{2}}{2\left(p_{0}-p_{a}\right)}\right)=0 if p_{a}<p\leq p_{0}\)

\(G=F if p>p_{0}\)

Поскольку давление равно \(p_{0}\), то функция текучести F и функция пластического течения G одинаковы и выполняется следующее условие:

Давление \(p\_{0}\) можно рассчитать с помощью поверхности текучести, где \(\frac{\partial F}{\partial p}| p_{0}=0\). Если G определено как:

Параметр \(\psi\) можно определить, используя напряжение фон Мизеса при давлении, \(p_{0}\) в функции.

Рисунок 194: Поверхность текучести LAW81 с пластическим течением

Разрушение

Пластичное

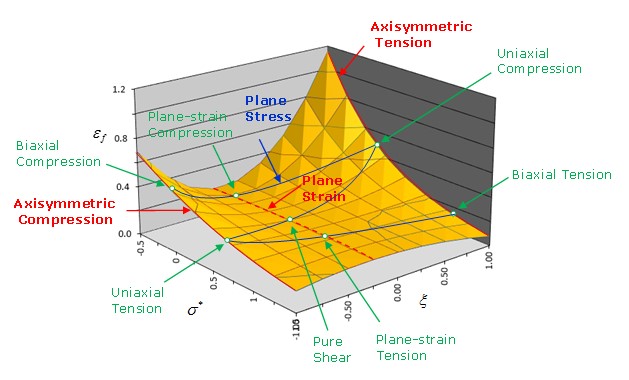

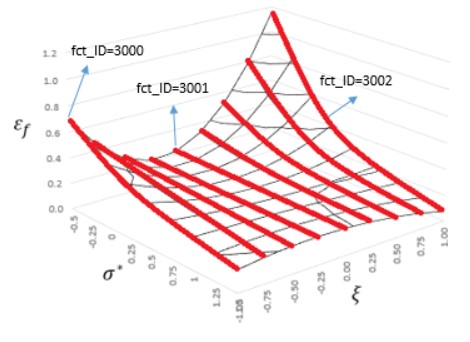

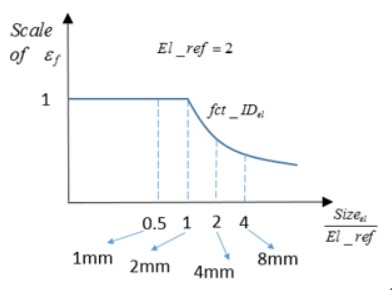

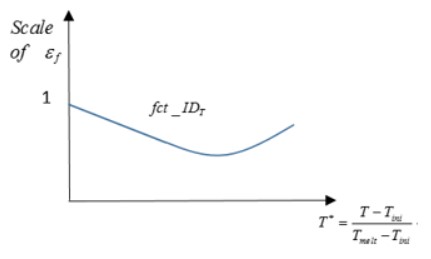

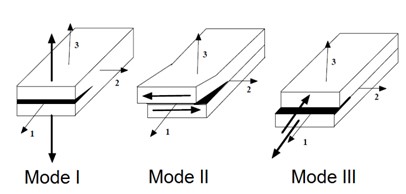

Модели разрушения /FAIL/BIQUAD, /FAIL/JOHNSON и /FAIL/TAB1 определяют

разрушение материала, связывая пластическую деформацию при разрушении с

напряженным

состоянием в материале.

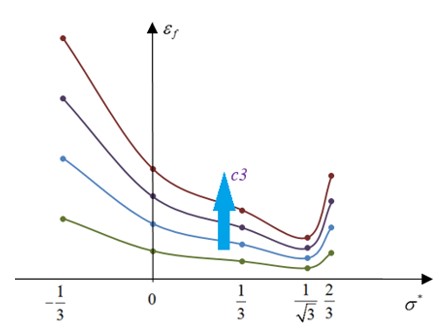

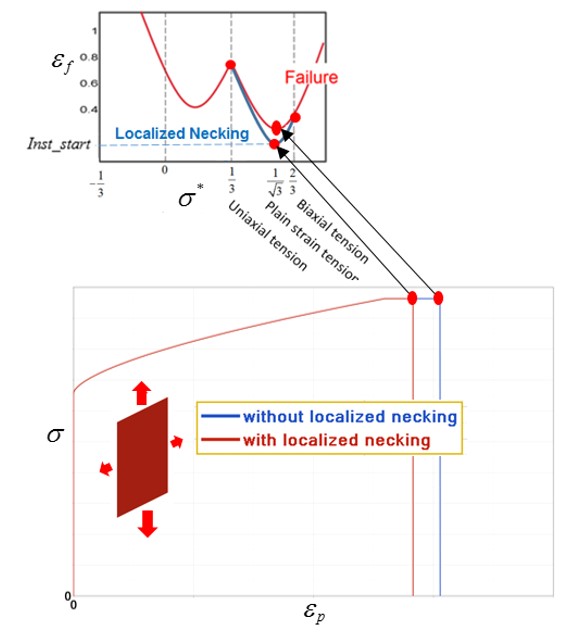

Эти модели разрушения часто используются для описания пластичного разрушения материалов. Состояние напряжения в материале можно определить с помощью триаксиальности напряжения.

Триаксиальность напряжения (нормализованное среднее напряжение)

Для пластичных материалов состояние напряжения (сжатие, сдвиг, растяжение и т. д.) материала влияет на значение пластической деформации, при которой материал разрушится. Важная и полезная характеристика для описания состояния напряжения, трехосность напряжения определяется как:

Где,

:math:`sigma_{m}=frac{1}{3}big{(}sigma_{1}+sigma_{2}+sigma_{3}big{)}`Среднее (гидростатическое) напряжение

\(\sigma_{VM}=\sqrt{\frac{1}{2}\big{[}\big{(}\sigma_{1}-\sigma_{2}\big{)}^{2}+\big{(}\sigma_{2}-\sigma_{3}\big{)}^{2}+\big{(}\sigma_{3}-\sigma_{1}\big{)}^{2}\big{]}}\) Мизес стресс

Значения трехосности для некоторых состояний общего напряжения можно получить следующим образом:

При чистом растяжении:

\(\sigma_{2}=\sigma_{3}=0\) then \(\sigma^{*}=\frac{\sigma_{m}}{\sigma_{VM}}=\frac{1}{3}\)

При двухосном сжатии:

\(\sigma_{1}=\sigma_{2}\), и \(\sigma_{3}=0\), тогда \(\sigma^{*}=\frac{\sigma_{m}}{\sigma_{VM}}=-\frac{2}{3}\)

Трехосность напряжения для различных напряженных состояний:

Трехосность напряжения \(\sigma^{*}\) Напряженное состояние

\(-\frac{2}{3}\) Двуосное сжатие

\(-\frac{1}{3}\) Одноосное сжатие

\(\textbf{0}\) Чистый сдвиг

\(\frac{1}{3}\) Одноосное растяжение

\(\frac{1}{\sqrt 3}\) Плоская деформация

\(\frac{2}{3}\) Двуосное растяжение

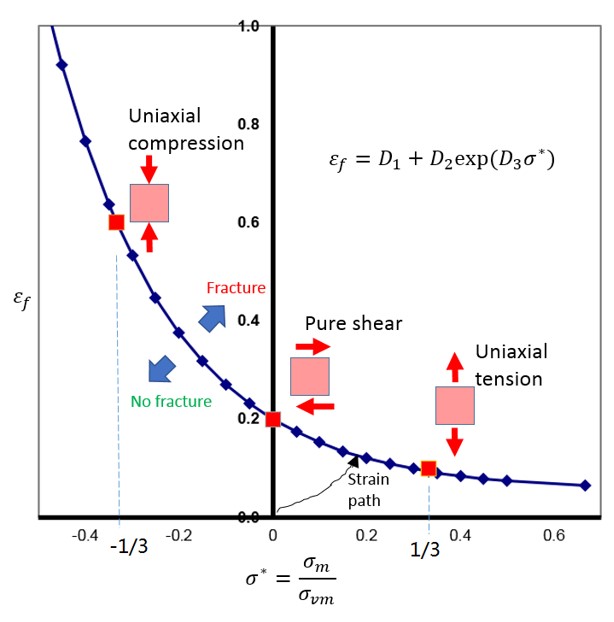

/FAIL/JOHNSON

Модель разрушения Джонсона-Кука часто используется для описания пластичного разрушения металлов. Она использует уравнение Джонсона-Кука для определения деформации разрушения как функции трехосности напряжения.

В модели неудач Джонсона-Кука есть три части;

Где

\(\varepsilon_{f}\) Пластическая деформация разрушения

\(\varepsilon^{*}=\frac{\varepsilon}{\varepsilon_{0}}\) Текущая скорость деформации, деленная на входную опорную скорость деформации

\(T^{*}\) Рассчитано по материальному закону или /HEAT/MAT

Игнорируя влияние скорости деформации и температуры, график разрушения Джонсона-Кука выглядит следующим образом:

Рисунок 195: Пример графика модели разрушения Джонсона-Кука

Пластические деформации над кривой представляют собой разрушение материала, а под кривой — отсутствие разрушения материала.

В простом случае, когда учитывается только влияние трехосности, деформация разрушения равна:

Используя 3 точки данных разрушения из теста:

\(\varepsilon_{f}=0,1585\) при одноосном растяжении (\(\sigma^{\bullet}=1/3)\)

\(\varepsilon_{f}=0,19\) при чистом сдвиге (\(\sigma^{\bullet}=0)\)

\(\varepsilon_{f}=0,2419\) при одноосном сжатии (\(\sigma^{\bullet}=-1/3)1\)

Параметры \(\mathrm{D}_{1}, :math:\)mathrm{D}_{2}` и \(\mathrm{D}_{3}\) можно вычислить аналитически, решив следующие уравнения:

Обработка отказа элемента

Метод накопленного повреждения используется для суммирования величины пластической деформации, которая произошла в элементе, с использованием:

Что происходит, когда \(D\geq 1\) зависит от значений флагов отказа элемента (\(I_{fail_sh} и I_{fail_so})\) и флага формулировки XFEM (\(I_{\textit{xfem}})\). Когда формулировка XFEM не используется (\(I_{\textit{xfem}})=0\), следующая таблица суммирует различные варианты флага отказа элемента:

Таблица 18: Вариант отказа элемента

Элемент |

Отказ элемента флаг |

\(D\geq 1\) |

|

|---|---|---|---|

Shell |

\(I_{fail_sh}\) =1 (Default) |

в 1 IP или слой |

Элемент удален. |

Shell |

\(I_{fail_sh}\) =2 |

в 1 IP или слой |

тензор напряжения 0 im IP или слой |

Shell |

\(I_{fail_sh}\) =2 |

Все IP или слои |

Элемент удален. |

Solid |

\(I_{fail_sh}\) =1 (по умолчанию) |

в 1 IP |

Элемент удален. |

Solid |

\(I_{fail_sh}\) =2 |

в 1 IP |

тензор напряжения устан-н на 0 im IP |

Solid |

\(I_{fail_sh}\) =2 |

все IP |

тензор напряжения уст-н 0 в элементы |

Подробную информацию о формулировке XFEM (\(I_{\textit{xfem}})=1)\),

можно найти в /FAIL/JOHNSON.

Повреждение, D, можно отобразить в файлах анимации с помощью

/ANIM/SHELL/DAMA или /ANIM/BRICK/DAMA. Это покажет риск

материального повреждения.

/FAIL/BIQUAD

В PRADIOS /FAIL/BIQUAD является наиболее удобной для пользователя моделью разрушения для

пластичных материалов. Она использует упрощенные, нелинейные критерии разрушения на основе деформации с линейным накоплением повреждений.

Разрушение описывается двумя параболическими функциями, рассчитанными с использованием подгонки кривой из до 5 введенных пользователем деформаций разрушения.

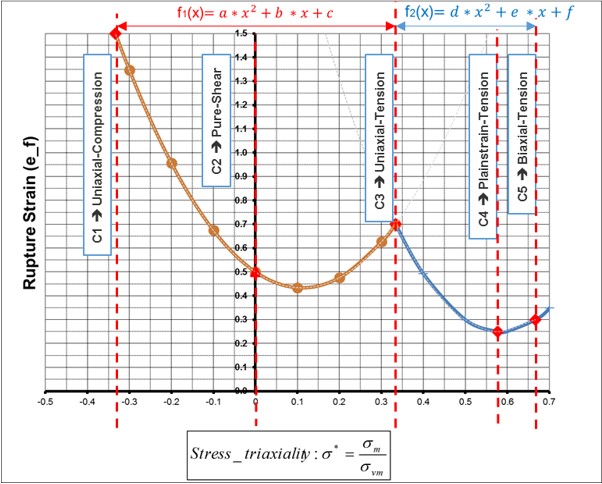

По умолчанию /FAIL/BIQUAD (``S-Flag``=1) использует две параболические кривые для описания пластической деформации разрушения \(\varepsilon_{f}\), как

функции трехосности напряжения \(\sigma\). Две

параболические кривые используют:

Где,

\(a, b, c, d, e,\) и \(f\) Параболические коэффициенты

\(x\) Трехосность напряжения

\(f_{1}(x)\) и \(f_{2}(x)\) Пластическая деформация разрушения

Рисунок 196: /FAIL/BIQUAD Кривая деформации разрушения, состоящая из 2 параболических

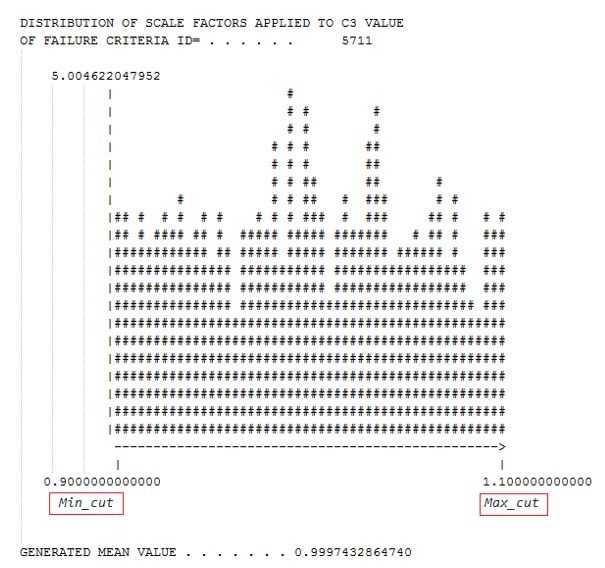

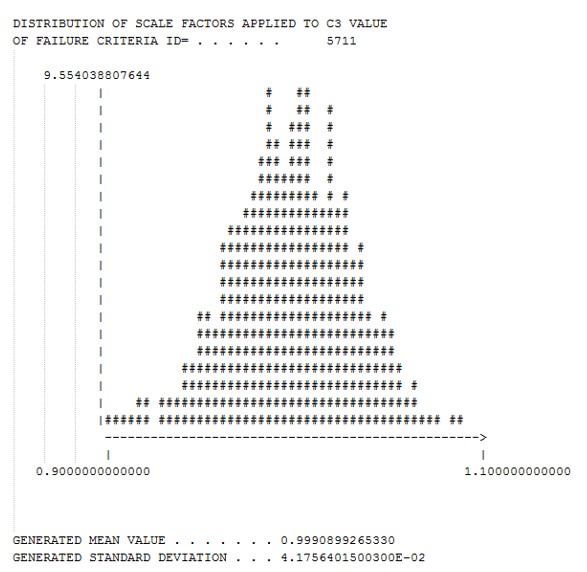

Параболические коэффициенты \(a, b, c, d, e,\) и \(f\) вычисляются PRADIOS с использованием

подгонки кривой на основе входных значений пластической деформации разрушения c1-c5. Если

рассчитанные параболические кривые деформации разрушения имеют отрицательные значения деформации разрушения, эти отрицательные значения будут заменены на деформацию разрушения 1E-6, что приводит к очень высокому накоплению повреждений и

хрупкому поведению. Результаты подгонки кривой находятся в файле Starter

*0000.out.

Би-квадратичный ОТКАЗ

- - - - - - - - - - - - - -

c1. . . . . . . . . . . . . . . . . . .= 0.2419E+00

c2. . . . . . . . . . . . . . . . . . .= 0.1900E+00

c3. . . . . . . . . . . . . . . . . . .= 0.1585E+00

c4. . . . . . . . . . . . . . . . . . .= 0.1437E+00

c5. . . . . . . . . . . . . . . . . . .= 0.1394E+00

КОЭФФИЦИЕНТЫ ПЕРВОЙ ПАРАБОЛЫ

- - - - - - - - - - - - - -

a . . . . . . . . . . . . . . . . . . .= 0.9180E-01

b . . . . . . . . . . . . . . . . . . .= -0.1251E+00

c . . . . . . . . . . . . . . . . . . .= 0.1900E+00

КОЭФФИЦИЕНТЫ ВТОРОЙ ПАРАБОЛЫ

- - - - - - - - - - - - - -

d . . . . . . . . . . . . . . . . . . .= 0.3753E-01

e . . . . . . . . . . . . . . . . . . .= -0.9483E-01

f . . . . . . . . . . . . . . . . . . .= 0.1859E+00

Определения пластических деформаций разрушения c1–c5 следующие:

- c1

Пластическая деформация разрушения при одноосном сжатии

- c2

Пластическая деформация разрушения при сдвиге

- c3

Пластическая деформация разрушения при одноосном растяжении

- c4

Пластическая деформация разрушения при плоском растяжении

- c5

Пластическая деформация разрушения при двухосном растяжении

Параметры ввода M-Flag

В зависимости от параметра ввода M-Flag существует три различных способа определения значений c1-c5.

M-Flag=0, Пользовательские данные испытаний В этом случае необходимо ввести c1-c5, что представляет собой пластическую деформацию разрушения для 5 различных напряженных состояний. В идеале эти данные следует получить из испытаний или от поставщика материалов.

M-Flag=1-7, Предопределенные данные материалов Если данные о деформации разрушения недоступны, можно выбрать из 7 предопределенных материалов. На рисунке 197 показаны кривые пластической деформации при разрушении для 7 материалов.

Примечание: Предопределенные значения предоставляются для раннего исследования конструкции, и вы несете ответственность за проверку того, что их материал имеет те же свойства… image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image72.png

Примечание: Предопределенные значения предоставляются для раннего исследования конструкции, и вы несете ответственность за проверку того, что их материал имеет те же свойства… image:: vertopal_75794439f47d439ba01f734ac3f4dcc1/media/image72.png- width

4.60333in

- height

3.36667in

Рисунок 197: Предопределенные кривые разрушения материала

M-Flag=99, Ввод коэффициента деформации пластического разрушения, r1-r5

Последний метод ввода — ввести пластическую деформацию разрушения при одноосном растяжении, c3, и коэффициенты пластической деформации разрушения для остальных четырех напряженных состояний. Эти коэффициенты определяются как:

- r1

Отношение пластической деформации разрушения, одноосное сжатие (c1) к одноосному растяжению (c3), поэтому \(c1=r1\cdot c3\)

- r2

Отношение пластической деформации разрушения, чистый сдвиг (c2) к одноосному растяжению (c3), поэтому \(c2=r2\cdot c3\)

- r4

Отношение пластической деформации разрушения, плоское растяжение (c4) к одноосному растяжению (c3), поэтому \(c4=r4\cdot c3\)

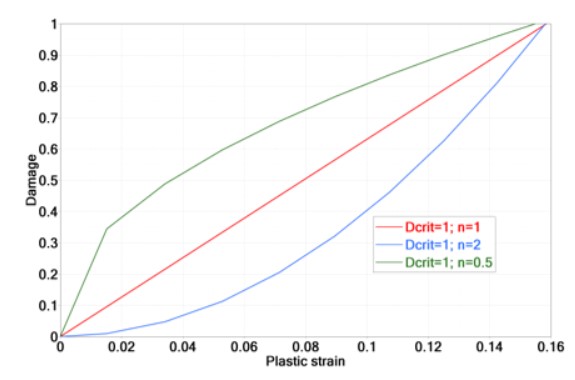

- r5