Где, \(K_{3}, K_{2}, K_{1}\) являются жесткостями виртуального интерфейса, также называемыми межслойной жесткостью. Эти значения могут быть вычислены как: .. math:: K_{3}=frac{2E_{33}}{t}tag{196}

Где,

\(t\) Толщина виртуального интерфейса. Можно предположить, что она составляет 1/5 толщины слоя.

\(G_{13}, G_{23}, E_{33}\) Из верхнего или нижнего слоя.

\(d_{i}\) (при \(i\) =1,2,3), переменная повреждения.

Имеет диапазон от 0 до 1. Начинает накапливаться, как только композит достигает \(Y_{0}\).

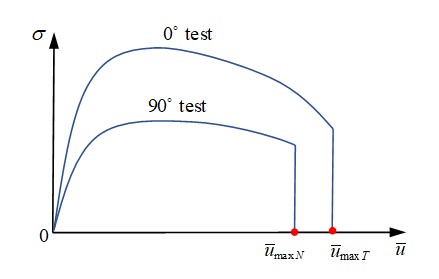

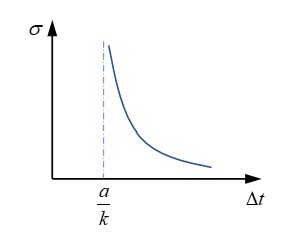

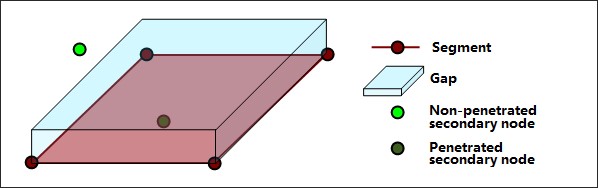

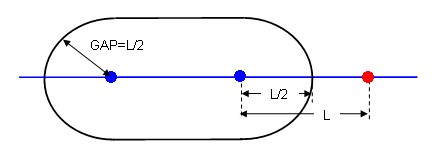

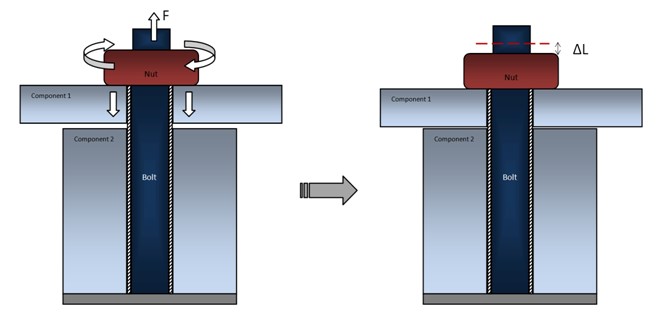

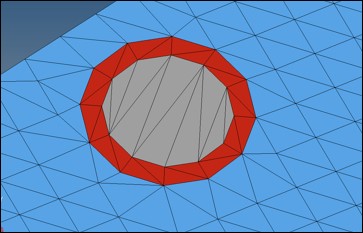

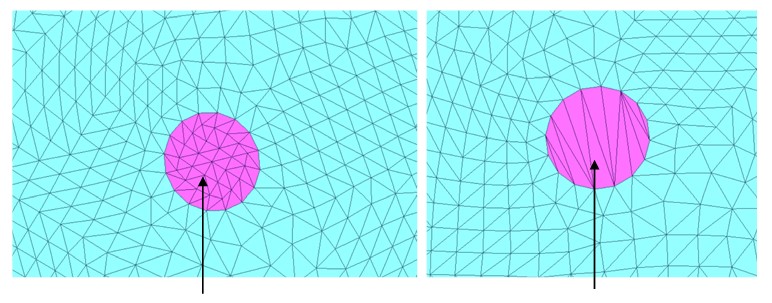

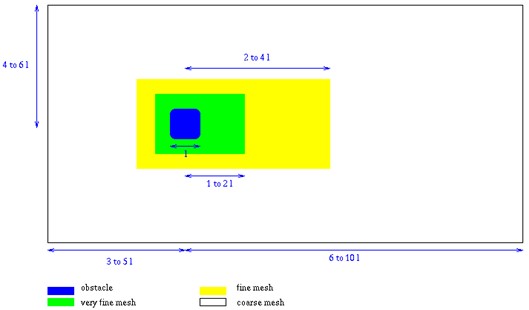

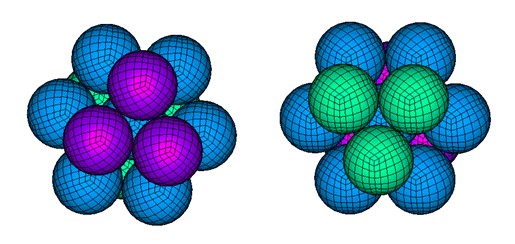

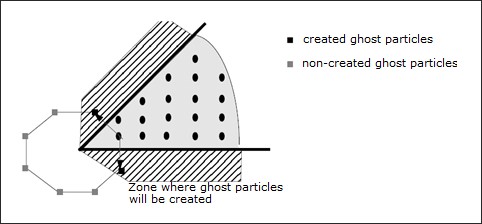

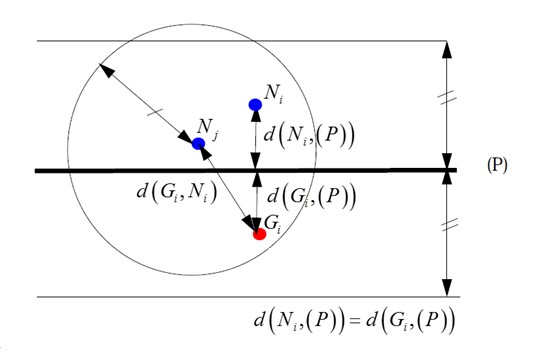

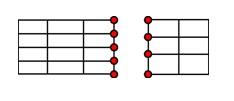

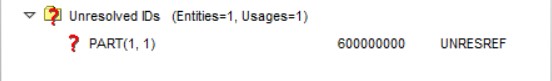

Пример режима I, во время натяжения в направлении 3, в начале \(d_{3}\) всегда остается 0, пока термодинамическая сила \(Y_{d_{3}}\) не достигнет \(Y_{0}\) (левый рисунок). .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/im8age1.jpg

- width

5.84217in

- height

2.03351in

Рисунок 267:

После достижения \(Y_{0}\) переменная повреждения начинает увеличиваться, и когда она достигает 1, \(d_{3}=1\) (термодинамическая сила \(Y_{d_{3}}\) в этой точке становится критическим повреждением \(Y_{c}\)). Композит можно считать полностью расслоившимся и его можно немедленно удалить или можно уменьшить напряжение. В PRADIOS эта опция используется для моделирования экспоненциального снижения напряжения, и напряжение при \(Y_{c}\) равно \(\sigma_{d}(t_{r})\) (снижение напряжения при повреждении).

Связь с термодинамической силой \(Y_{d_{i}}\) и \(d_{i}\) следующая:

Если \(d\geq 1\), то принимаем d =1

Если d <1, то d является функцией Y (закон оценки ущерба):

\(Y=Y_{d_{3}}+\gamma_{1}Y_{d_{1}}+\gamma_{2}Y_{d_{2}}\text{with}Y_{d_{i}}\left|=\sup Y_{d_{i}}\right|_{\leq t}\)

Здесь \(\gamma_{1},\gamma_{2}\) являются масштабными коэффициентами для рассмотрения двух других режимов расслоения. Это может быть подтверждено экспериментами (тест образца DCB и ENF:sup:21).

В примере режима I \(\gamma_{1},\gamma_{2}\) может быть 0, поскольку это чистое расслоение в направлении 3, и тогда \(Y=Y_{d_{3}}\) соотношение \(Y_{d_{3}}\) и \(d_{3}\) равно:

Рисунок 268:

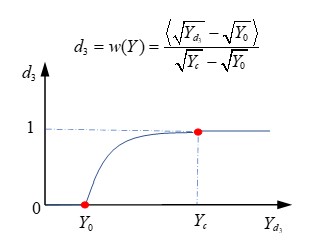

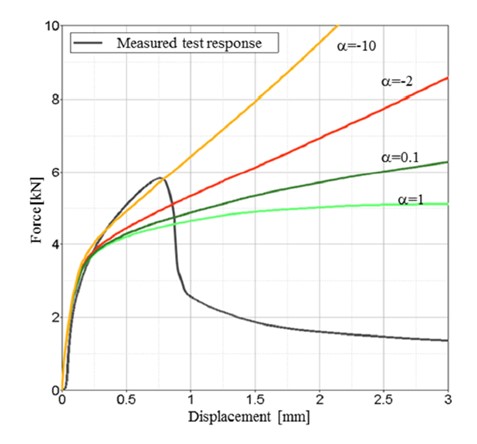

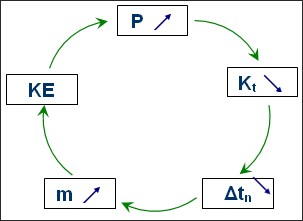

Как быстро будет увеличиваться переменная повреждения? Скорость повреждения \(d\) (также называемая законом оценки повреждения) вычисляется как:

Если \(d=1\), то \(\dot{d}=\textit{const.}\)

Если \(d<1\), то \(\dot{d}=\frac{k}{a}\big{[}1-\exp\big{(}-\alpha\big{(}w(Y)-d\big{)}\big{)}\big{]}\)

\(\frac{k}{a}\) - это максимальная скорость повреждения, что означает минимальную продолжительность явления отказа. Его обратная величина, \(\frac{a}{k}\) называется характерным временем, которое можно получить с помощью одномерного испытания на растяжение.

23

Рисунок 269:

Через растяжение образца с различным напряжением для нахождения минимального времени композитного повреждения \(\Delta \)sigma-Delta t` является вертикальной асимптотой, соответствующей характерному времени \(\frac{a}{k}\).

Рисунок 270:

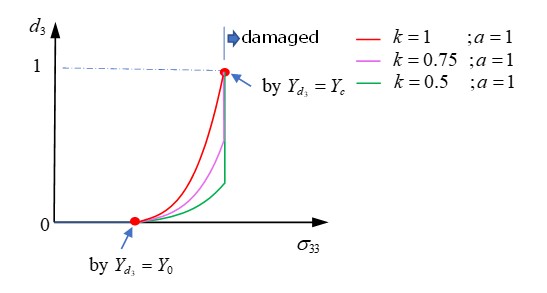

Параметры (a) и (k) управляют законом оценки повреждений. Например, при постоянном параметре (a) (здесь (a=1)) уменьшение значений (k) приводит к более хрупкому разрушению композита.

Рисунок 271:

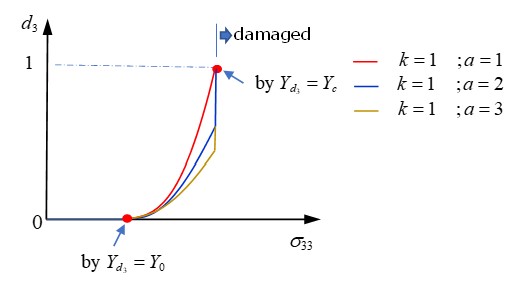

При постоянном параметре (k) (здесь (k=1)) увеличение значений (a) приводит к более хрупкому разрушению композита.

Рисунок 272:

/FAIL/CHANG

При отказе Чанга-Чанга рассматриваются два основных режима отказа.

Режим волокна: композит выходит из строя из-за разрыва волокна при растяжении или изгиба волокна при сжатии.

Режим матрицы: композит выходит из строя из-за разрушения матрицы при растяжении или сжатии.

Этот критерий отказа используется только для элементов оболочки.

Повреждение критерий |

Если D =1, тогда неудача. Если \(0\leq D<1\) D, тогда никаких неудач. с \(D=Max(e_{f}2,e_{c}2,e_{m} 2,e_{d}2)\). |

|

Волокно поломка |

Режим растяжения волокна \(\sigma_{11}>0\) |

\(e_{f}2=\big{(}\frac{\sigma_{11}} {\sigma_{1}^{t}}\big{)}^{2}+\beta\big{(} \frac{\sigma_{12}}{\sigma_{12}}\big{)} ^{2}\) |

\(\sigma_{11}<0\) |

:math:`e_{c}2=big{(}frac{sigma_{11}} {sigma_{1}^{c}}big{)}^{2}` |

|

|

Режим растяжения матрицы \(\sigma_{22}>0\) |

\(e_{m}2=\big{(}\frac{\sigma_{11}} {\sigma_{1}^{t}}\big{)}^{2}+\beta\big{(} \frac{\sigma_{12}}{\sigma_{12}}\big{)} ^{2}\) |

\(\sigma_{22}<0\) |

:math:`e_{d}2=big{(}frac{sigma_{22}} {2sigma_{12}}big{)}^{2}+big{[}big{(} frac{sigma_{2}^{c}}{2sigma_{12}} big{)}^{2}-1big{]}frac{sigma_{22}} {sigma_{2}^{c}}+big{(}frac {sigma_{12}}{sigma_{12}}big{)}^{2}` |

|

Где,

направление 1 Направление волокон.

\(\sigma_{1}^{t},\sigma_{1}^{c}\) Прочность волокон на растяжение/сжатие.

\(\sigma_{2}^{t},\sigma_{2}^{c}\) Прочность матрицы. Растягивающая или сжимающая нагрузка в направлении 2 (поперечном направлению 1).

\(\sigma_{12}\) Прочность на сдвиг в плоскости композитного слоя.

\(\beta\) Масштабный коэффициент сдвига, который можно определить экспериментально.

Уменьшение напряжения при повреждении

После достижения критерия повреждения:

HASHIN:

\(D=Max(F_{1},F_{2},F_{3},F_{4})\geq 1\)

PUCK:

\(D=Max(e_{f}(tensile),e_{f}(compression),e_{f}(ModeA),e_{f}(ModeB),e_{f}(ModeC))\geq 1\) • LAD_DAMA:

\(d\geq 1\)

CHANG:

\(D=Max(e_{f}2,e_{c}2,e_{m}2,e_{d}2)\geq 1\)

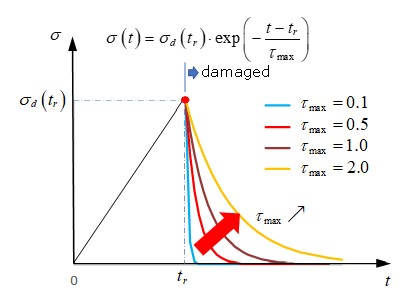

Напряжения начинают уменьшаться и уменьшаются постепенно с использованием экспоненциальной функции, чтобы избежать числовых нестабильностей.

\(=\sigma_{d}(t_{r})\cdot\exp\Big{(}-\frac{t-t_{r}}{t_{\max}}\Big{)}\)

с, \(t\geq t_{r}\)

Опция \(\tau_{\max}\) контролирует, насколько постепенно уменьшается напряжение при повреждении.

Рисунок 273:

Где,

\(\sigma_{d}(t_{r})\) Компоненты напряжения при достижении повреждения \(D\geq 1\).

\(t_{r}\) Время \(\sigma_{d}(t_{r})\).

\(t_{max}\) Время динамической релаксации.

Чем выше значение \(t_{max}\), тем медленнее снижается напряжение при повреждении.

Обычно для прогнозирования разрушения ламинированных композитов при динамической нагрузке требуется 10~20 временных шагов моделирования.

Hashin, Z., “Failure Criteria for Unidirectional Fiber Composites,” Journal of Applied Mechanics, Vol. 47, 1980, pp. 329-334.

Puck, J. Kopp, and M. Knops., “Failure analysis of FRP laminates by means of physically based phenomenological models”. Composites Science Technology, 62. pp. 1633-1662. 2002.

Puck, J. Kopp, and M. Knops. “Guidelines for the determination of the parameters in Puck’s action plane strength criterion”. Composites Science Technology 62. pp. 371-378. 2002.

Gornet, “Finite Element Damage Prediction of Composite Structures”.

Ladevèze, P., Allix, O., Douchin, B., Lévêque, D., “A Computational Method for damage Intensity Prediction in a Laminated Composite Structure”, Computational mechanics—New Trends and Applications In: Idelsohn, S., Oñate E., and Dvorkin E., (eds.) CIMNE, Barcelona, Spain (1998).

Gama B.A., Gillespie J.W., Punch Shear Behavior of Composites at Low and High Rates[M]// Fracture of Nano and Engineering Materials and Structures. Springer Netherlands, 2006.

Allix, O. & Deü, Jean-François. (1997). Delay-damage modeling for fracture prediction of laminated composites under dynamic loading. Engineering Transactions. 45. 29-46.

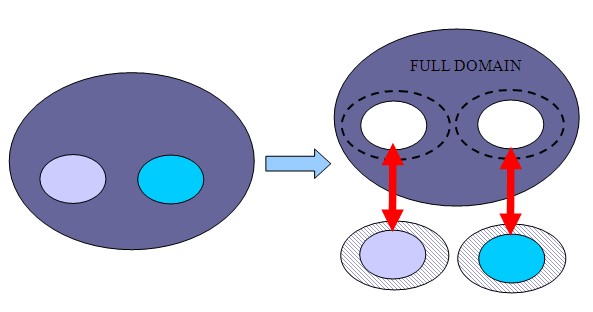

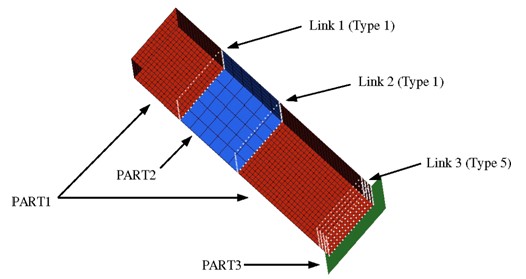

Соединения

Точечная сварка (болтовое или клеевое соединение)

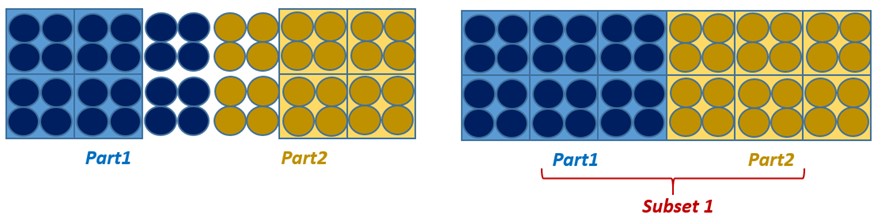

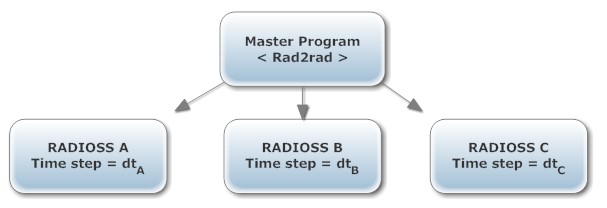

Существует три различных способа моделирования точечных сварных швов:

Узловое соединение

Пружинное (

/PROP/TYPE13) соединениеТвердое соединение

Пружинное (/PROP/TYPE13) соединение и твердое соединение также могут

использоваться для моделирования болтового или клеевого соединения (клея).

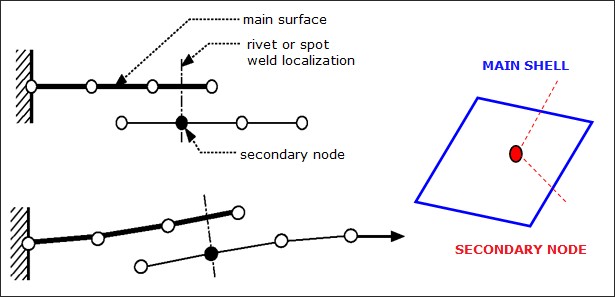

Узловое соединение

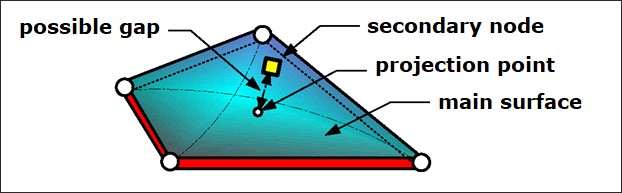

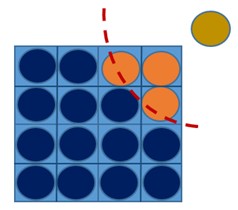

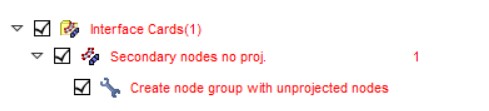

Единый интерфейс TYPE2 с первой поверхностью в качестве основной стороны и некоторыми узлами со второй поверхности в качестве вторичных узлов: При таком решении сетка основной поверхности может быть независимой от места точечной сварки. Проблемы песочных часов исчезают на основной поверхности. На второй оболочке поверхностная сетка должна учитывать место точечной сварки, и проблема песочных часов останется. Основная проблема с этим подходом к моделированию заключается в недеформируемости соединения и его бесконечной прочности.

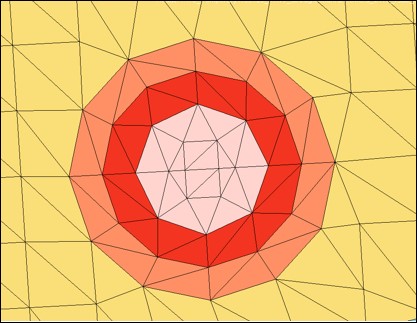

Рисунок 274: Пример соединения между 2 поверхностями оболочки

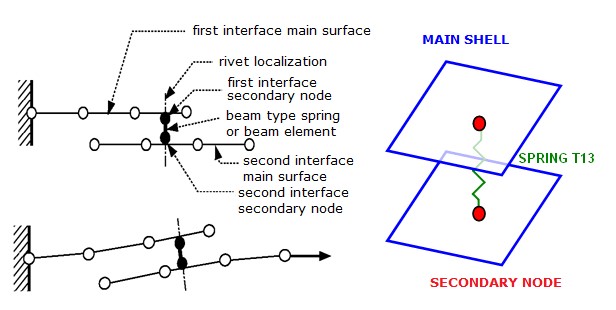

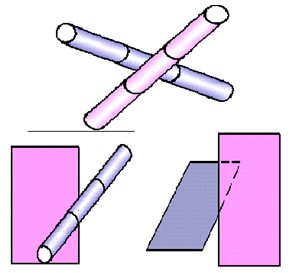

Пружинное (/PROP/TYPE13) соединение

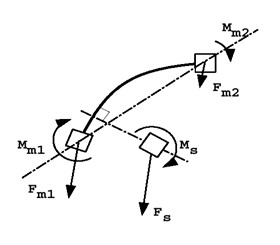

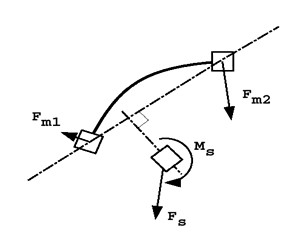

Два связанных интерфейса и пружина: использование двух связанных интерфейсов обеспечит полное симметричное решение, позволяющее создать свободную сетку на двух поверхностях и избежать песочных часов. Точечный шов моделируется пружинным элементом балочного типа. Пружинный элемент использует независимые узлы, не связанные с элементами оболочки. Один из двух узлов расположен на первой поверхности (или рядом с ней, нет необходимости расположения точно на поверхности оболочки), а второй узел расположен на второй поверхности. Один связанный интерфейс соединяет один пружинный узел с первой поверхностью, а второй связанный интерфейс делает то же самое для второго узла на второй поверхности.

Рисунок 275: Моделирование точечной сварки

Создание точечной сварки с использованием этого метода является хорошим альтернативным решением при таком подходе место соединения не зависит от сетки оболочки. Это точнее, чем приведенное выше моделирование узлового соединения поскольку свойства точечной сварки вводятся непосредственно для пружины TYPE13.

Рисунок 276: Пружина TYPE13 — типичный ввод для точечной сварки

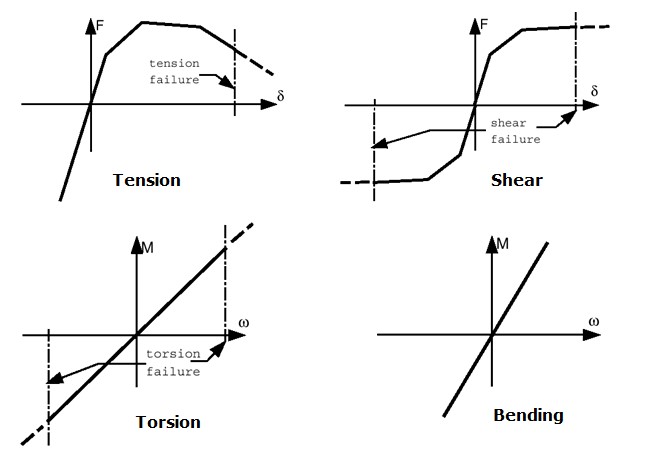

Более того, существует два разных способа моделирования разрыва точечной сварки:

Использовать критерии отказа, доступные для пружины TYPE13. Более подробную информацию см. в комментариях к критериям отказа в /PROP/TYPE13 (SPR_BEAM).

Использовать \(Spot_{flag}\) = 20, 21 или 22 в связанном контакте (связанный контакт (/INTER/TYPE2)).

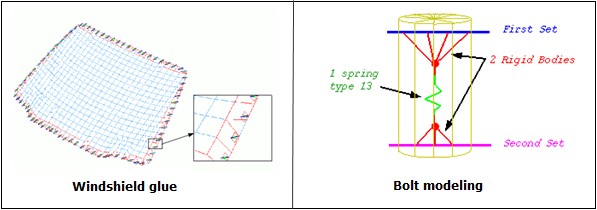

Примечание: Методика моделирования пружин TYPE13 для точечной сварки

Примечание: Методика моделирования пружин TYPE13 для точечной сваркиможет также использоваться для других видов соединений, таких как линии сварки, подгибка, клей и болты. Для моделирования болтов использование связанного интерфейса не обязательно, так как узлы оболочки можно поместить непосредственно в жесткие тела.

Рисунок 277: Примеры моделирования с использованием клея и болтов

Примечание: При связанном интерфейсе масса вторичного узла

передается в основные узлы, если \(Spot_{flag}\) установлен на 1. Инерция вторичного узла равномерно распределяется по основным узлам путем добавления массы, так что индуцированная инерция (в центре основной поверхности) равна инерции вторичного узла. Если основная поверхность является идеальным квадратом, добавленная масса вычисляется как:

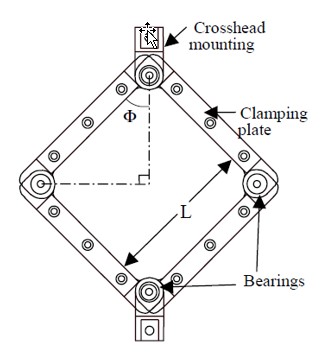

\(l_{s}=4\Delta m\cdot L^{2}\)

\(\Delta m\) : добавленная масса

\(L\) : расстояние между главным узлом и центром

\(l_{s}\) : инерция вторичного узла

Пока инерция вторичного узла реалистична, добавленная масса будет очень мала. Большая добавленная масса наблюдается, если вторичный узел находится слишком далеко от основной поверхности. Идеальным является расположение вторичного узла на плоскости основной поверхности, прямо в ее центре. Если это не так, вторичный узел имеет инерцию в центре поверхности оболочки:

\(l_{s}=m_{s}\cdot L_{s}2\)

\(m_{s}\) Масса вторичного узла

\(L_{s}\) Расстояние между вторичным узлом и центром

\(l_{s}\) Iнервия вторичного узла

Следовательно, новая добавленная масса устанавливается для основных узлов, так что инерция (из-за этой новой добавленной массы) равна инерции, из-за смещения вторичного узла.

Если \(Spot_{flag} =0\) , то нет никакой добавленной массы, так как инерция вторичного узла вместо этого передается как инерция основному узлу. Слишком большая добавленная инерция серьезно снизит точность.

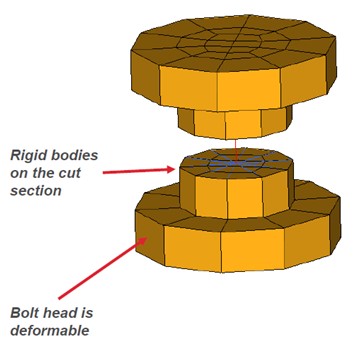

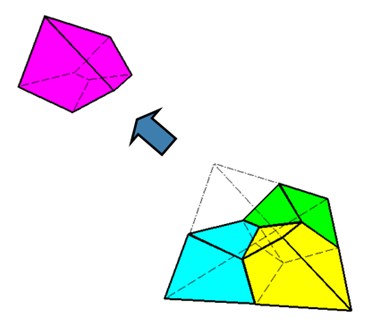

Твердая точечная сварка

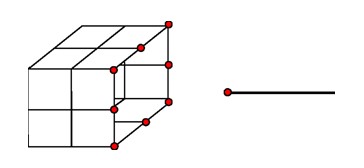

Использует 8-узловой элемент кирпича (с /PROP/TYPE43) и

/MAT/LAW59``+ ``/FAIL/CONNECT (или /MAT/LAW83``+ ``/FAIL/SNCONNECT) для моделирования

сплошных точечных сварных швов, что может обеспечить более точные результаты.

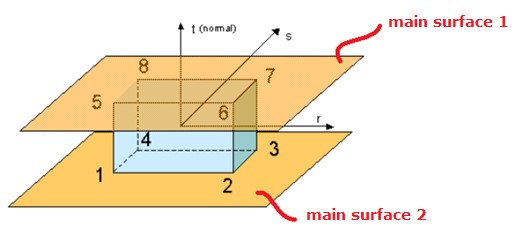

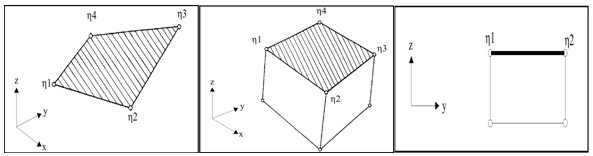

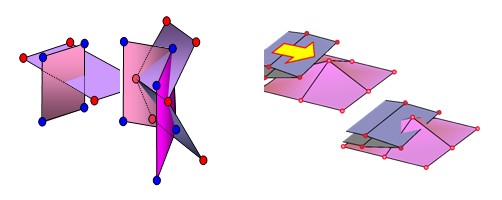

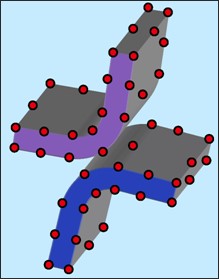

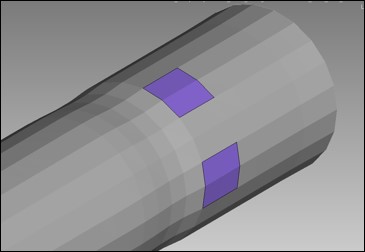

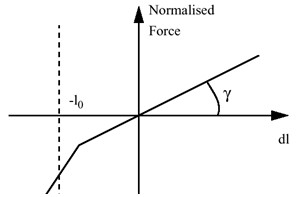

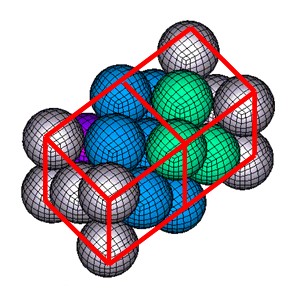

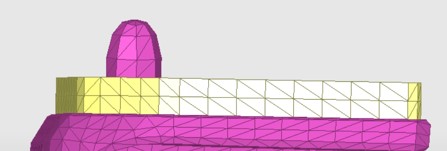

Твердый элемент и свойство

Элемент кирпича использует /PROP/TYPE43 и имеет 4 точки интегрирования

на плоскости сдвига, которая находится между плоскостью (1, 2, 3, 4) и плоскостью (5,

6, 7, 8). Есть одна точка интегрирования в нормальном направлении t.

Этот тип элемента не имеет самого временного шага, и его устойчивость обеспечивается его узловыми соединениями. Это означает, что толщина точечной сварки может быть очень малой. Эта характеристика очень полезна для моделирования клея.

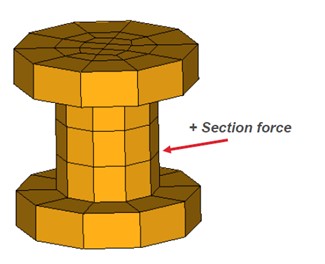

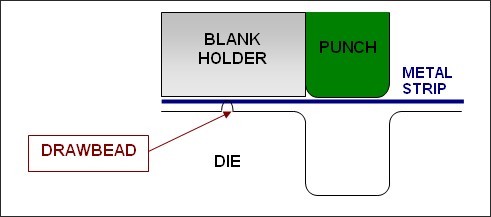

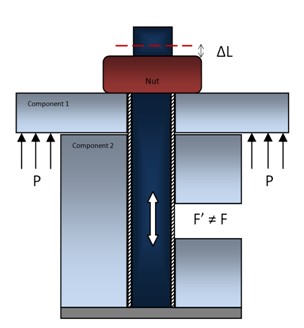

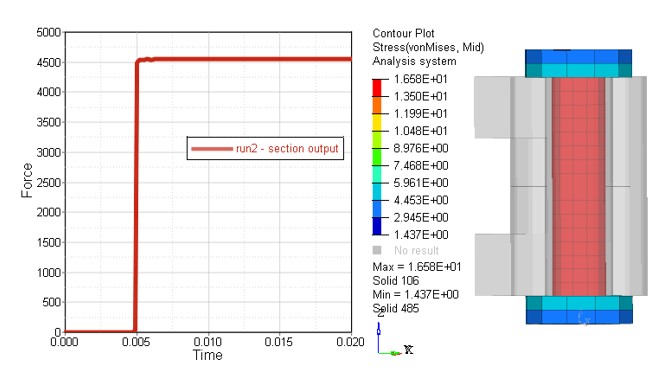

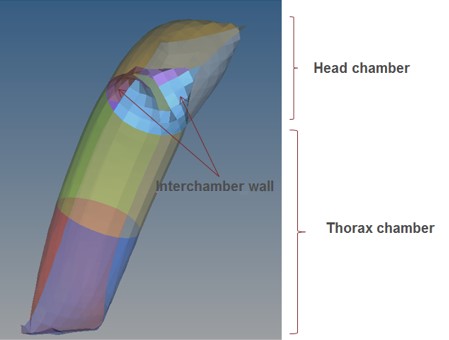

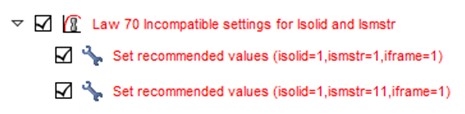

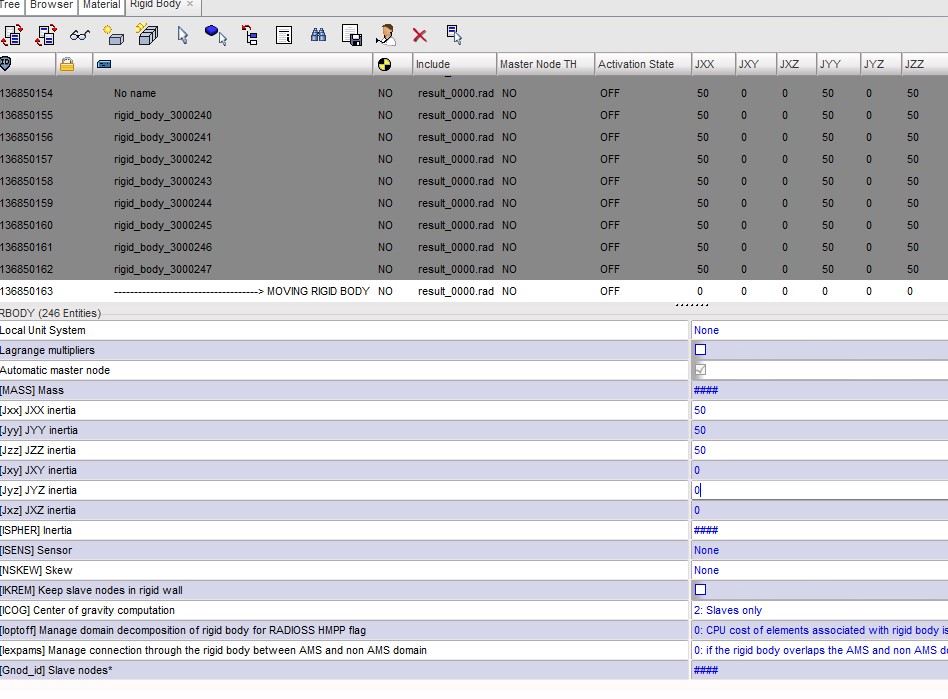

Рисунок 278: .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image16.jpg

- width

3.82533in

- height

1.75849in

Рисунок 279:

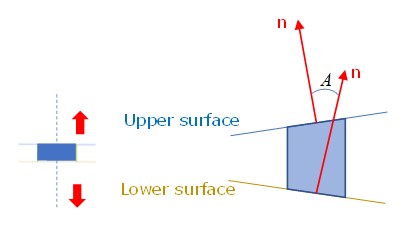

Соединение с листом оболочки (Shell Sheet)

/INTER/TYPE2 может использоваться для соединения сплошных точечных сварных швов с двумя (верхней и нижней) основными поверхностями. Узлы плоскости (1,2,3,4) привязаны к одной оболочке,

и узлы плоскости (5,6,7,8) привязаны к другой оболочке. Не допускается, чтобы

какая-либо другая плоскость (например, плоскость (1,4,8,5)) была привязана к оболочке.

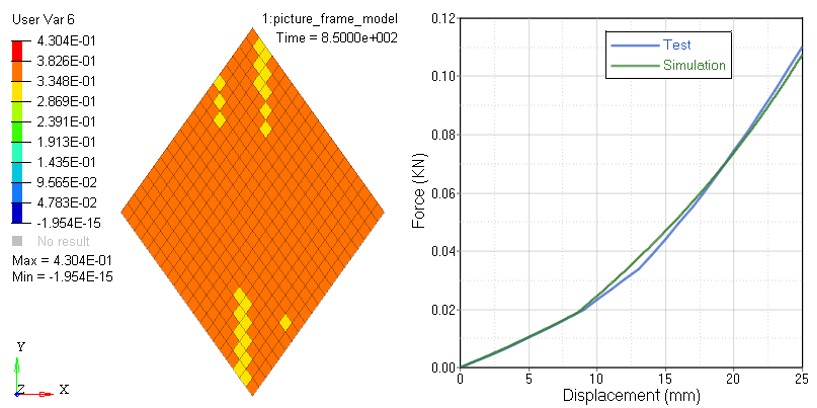

Модель материала и отказа

Сплошные точечные сварные швы в PRADIOS могут быть смоделированы с помощью

/MAT/LAW59``+ ``/FAIL/CONNECT (или /MAT/LAW83``+ ``/FAIL/SNCONNECT). Эта

модель материала должна быть проверена с четырьмя случаями нагрузки точечной сварки

испытаний.

Испытание на сдвиг (угол нагрузки и верхняя поверхность точечной сварки составляет 0 градусов ниже названного испытания на 0 градусов)

Нормальное испытание на растяжение (испытание 90 градусов),

Сдвиг и нормальное комбинированное испытание (например, испытание 30 градусов, испытание 45 градусов или испытание 90 градусов)

Испытание на момент (испытание на отслаивание)

Модуль упругости

Жесткость точечной сварки в разных испытаниях различна. В нормальном испытании она ниже, чем в испытании на сдвиг, из-за деформации верхнего и нижнего листов. Поэтому обычно измеренная жесткость берется из истинной кривой напряжения от смещения испытания на сдвиг.

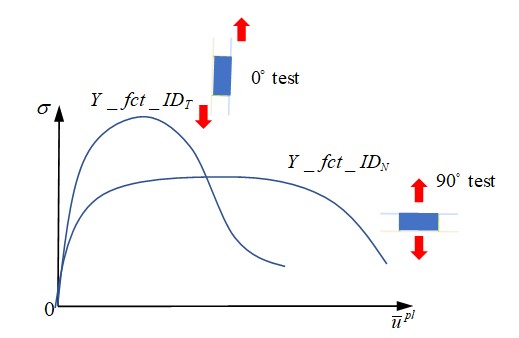

/MAT/LAW59+/FAIL/CONNECT

Кривая текучести материала:

В LAW59 запрашиваются кривые текучести материала точечной сварки в нормальном направлении и в направлении сдвига. Кривая текучести (\(Y\_fct\_ID_{N}\)) в нормальном направлении может быть определена из нормального испытания на растяжение (испытание под углом 90 градусов), а кривая текучести (\(Y\_fct\_ID_{T}\)) в направлении сдвига может быть определена из испытания на сдвиг (испытание под углом 0 градусов).

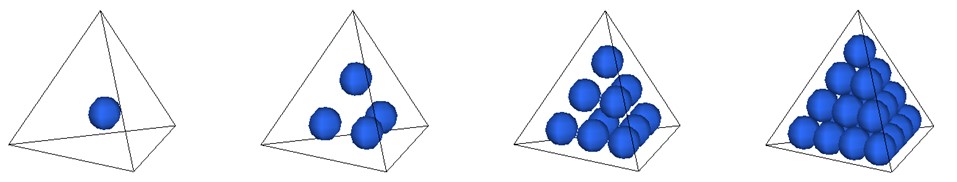

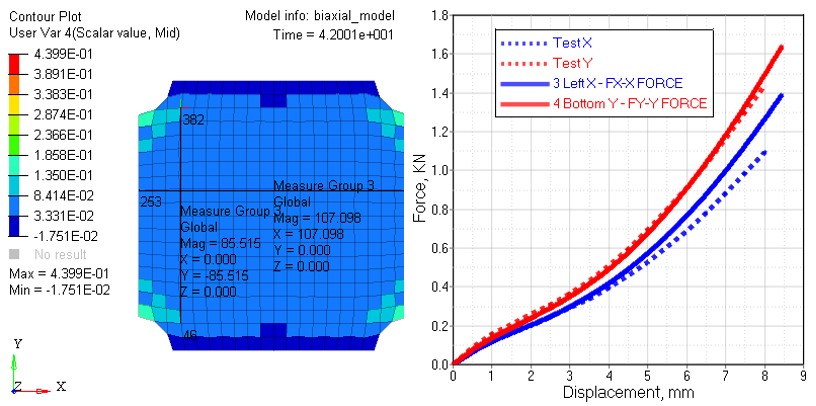

Рисунок 280:

В этом случае максимальное напряжение также описывается внутри кривых. Учитывая опорную скорость смещения \(SR_{ref}\) входной кривой текучести, PRADIOS будет учитывать эффект скорости смещения относительно этой опорной скорости смещения.

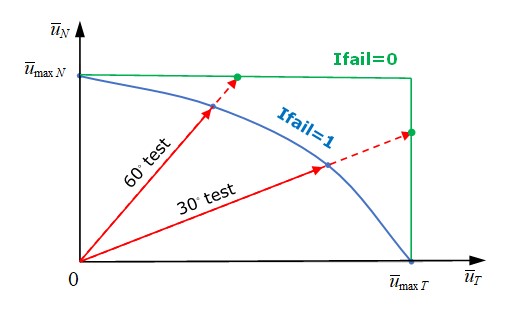

Разрушение точечной сварки:

Повреждение и отказ сплошной точечной сварки можно рассматривать с помощью

/FAIL/CONNECT. Критерии смещения и/или энергетические критерии могут использоваться для описания отказа точечной сварки. ◦ Для критериев смещения отказ происходит, когда достигается нормальное смещение или сдвиговое смещение в соответствии с двумя альтернативными типами поведения:∙ Несвязанный отказ (\(I_{fail} =0\): однонаправленный отказ)

with i = 33 для нормального направления и i = 13 или 23 для касательных направлений.

В нормальном испытании на растяжение (испытание на 90 градусов) элемент выходит из строя, как только достигается заданное пользователем максимальное смещение \(\overline{n}_{max N}\).

В испытании на сдвиг и растяжение (испытание на 0 градусов) элемент выходит из строя, как только достигается заданное пользователем максимальное смещение \(\overline{n}_{max T}\).

Рисунок 281:

В комбинированном режиме испытания (например, 30-градусный тест или 60-градусный тест) разрушение в сплошном точечном шве не учитывает сдвиг и нормальный эффект комбинированного напряжения. Разрушение в каждом направлении рассматривается отдельно. Элемент разрушается, как только любое из этих двух напряжений достигает соответствующего максимального смещения. Чтобы учесть комбинированные напряжения, вместо этого установите \(I_{fail} =1\), и тогда будет рассмотрен эффект комбинированного напряжения.

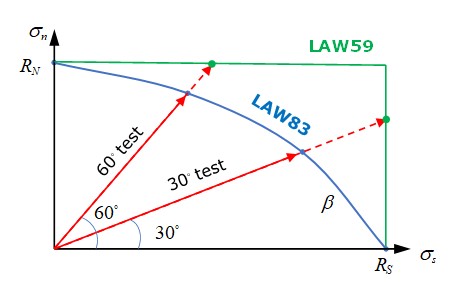

∙ Связанный отказ (\(I_{fail} =1\): многонаправленный отказ)

При \(I_{fail} =1\), в комбинированном режиме испытания элемент выходит из строя до достижения максимального напряжения или того, что ближе к реальности. Для описания поверхности разрушения кривой вам необходимо как минимум 4 различных комбинированных испытания для соответствия параметрам \(a_{N},a_{T},\exp_{N},\exp_{T}.\)

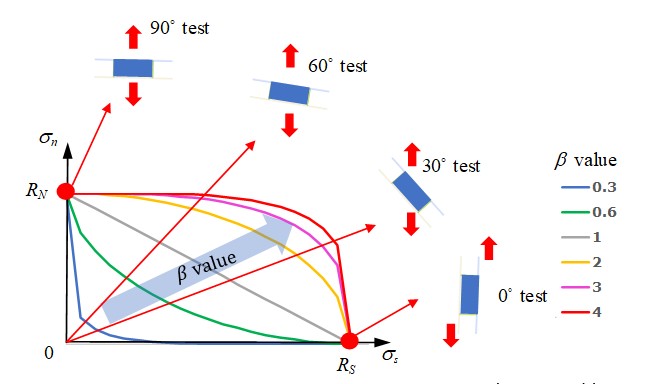

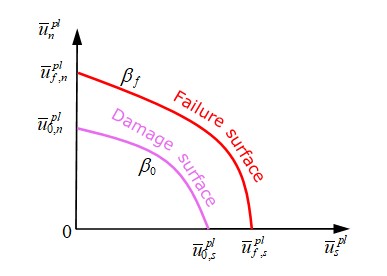

Рисунок 282: Поверхность разрушения

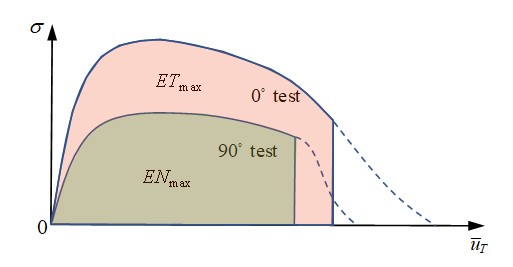

- ◦ Для энергетических критериев отказ происходит, когда достигается внутренняя энергия в нормальном направлении или внутренняя энергия в направлении сдвига, что соответствует максимальной внутренней энергии

\(EN_{max},ET_{max}.\)

Рисунок 283:

В комбинированном режиме испытания отказ элемента также рассматривается с учетом многонаправленного воздействия на внутреннюю энергию. Если введены внутренняя энергия в нормальном направлении и в направлении сдвига, элемент терпит неудачу, если удовлетворяется через:

Если ввести только полную внутреннюю энергию \(EI_{max,}\), элемент терпит неудачу, если удовлетворяется через:

Если введены оба \(EI_{max}\) и \(EN_{max,}ET_{max}\), элемент терпит неудачу, в зависимости от того, какой из этих двух критериев будет достигнут первым. Могут быть определены как критерии смещения, так и энергетические критерии. Элемент выходит из строя из-за того, какой критерий достигается первым. Удаление элемента происходит, когда одна точка интегрирования достигает критериев отказа, если \(I_{solid} =1\) или когда все точки интегрирования достигают критериев отказа, если \(I_{solid} =2\).

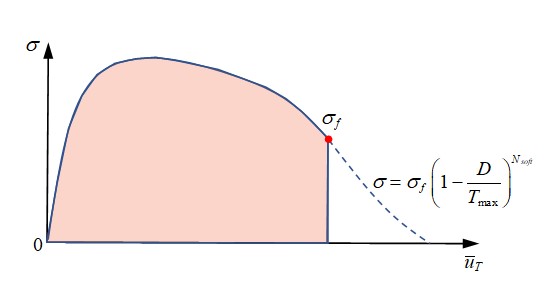

Размягчение точечной сварки:

После достижения критерия отказа (критерия смещения или критерия энергии) напряжение снижается до 0 напрямую или может постепенно управляться параметрами \(T_{max}\) и \(N_{soft}\) с:

Рисунок 284:

Рисунок 285 показывает влияние различных \(T_{max}\) на поведение снижения напряжения.

Рисунок 285:

/MAT/LAW83+/FAIL/SNCONNECT

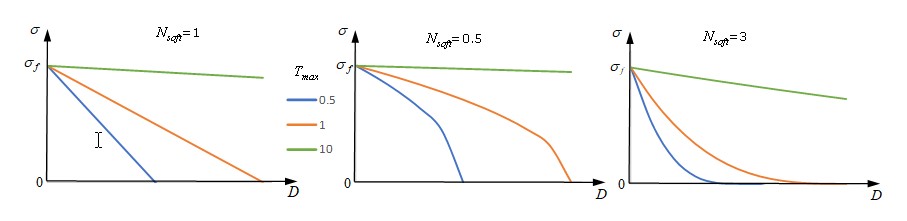

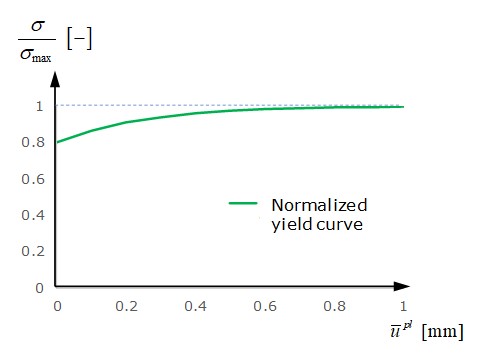

Кривая текучести материала:

В LAW83 кривая материала точечной сварки может быть введена с помощью \(fct\_ID_{1}\). Там, где во вводе LAW59 требуются две кривые текучести для нормального направления и направления сдвига, LAW83 использует только одну кривую. Эта кривая должна брать кривую текучести из испытания на сдвиг. Кроме того, кривая текучести \(fct\_ID_{1}\) для LAW83 не определяется как истинное напряжение против пластического смещения (как в LAW59), а должна быть нормализованной кривой напряжения против пластического смещения. Предел текучести нормализуется максимальным напряжением, которое вводится как параметры \(R_{N,}R_{S}\) в LAW83

Рисунок 286:

Кривая текучести отличается из-за различных комбинаций нормального напряжения и напряжения сдвига в точечной сварке. Это можно описать с помощью параметра \(\beta\) в LAW83 (он не учитывается в LAW59). Нормализованный предел текучести в LAW83 равен:

В случаях, когда эффект момента не учитывается, нормализованный предел текучести в LAW83 равен:

На рисунке 287 показана разница нормализованного максимального напряжения в комбинированных испытаниях между LAW83 и LAW59.

Рисунок 287:

На рисунке 288 показано влияние изменения \(\beta\) на нормализованное максимальное напряжение в комбинированных тестах с использованием LAW83.

Рисунок 288:

Параметр a используется для описания эффекта момента в точечной сварке.

Рисунок 289: Испытание на нецентральное растяжение (испытание на отрыв)

Используйте a для уменьшения максимального напряжения испытания на отрыв. — это синус угла между верхней и нижней поверхностью точечной сварки. Он изменяется во время деформации точечной сварки и находится в диапазоне [-1,1]. Параметр можно подогнать с помощью простой модели FEM для соответствия реальным экспериментальным данным. 24

Рисунок 290: Различные эффекты при испытании на отрыв при силе в зависимости от смещения

Влияние скорости смещения на кривую текучести материала также можно рассмотреть с помощью входных данных кривой \(fct\_ID_{N}\) и \(fct\_ID_{S}\).

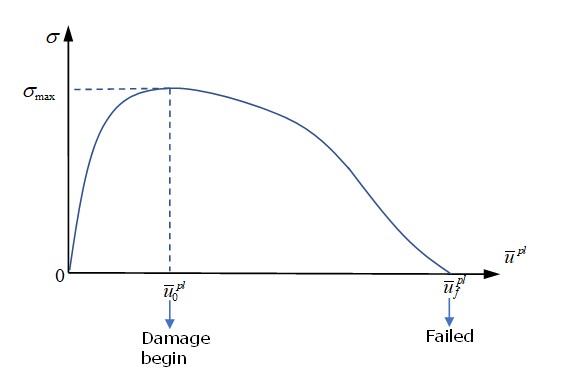

Повреждение и отказ материала:

Для отказа точечной сварки можно использовать

/FAIL/SNCONNECT. В этой модели отказа необходимы пластические смещения (как в нормальном, так и в направлении сдвига) начала повреждения и отказа.

Рисунок 291:

Для комбинированного режима испытания, аналогичного максимальному напряжению в LAW83, необходимо описать пластическое смещение в начале повреждения и описать пластическое смещение при отказе.

Рисунок 292:

Для точечной сварки с моментом (испытание на отслаивание), аналогично максимальному напряжению в LAW83, необходимо \(\beta_{0}\) для описания пластического смещения в начале повреждения во время испытания на отслаивание и \(\beta_{f}\) для описания пластического смещения при отказе испытания на отслаивание.

Таблица 20: Общие возможности двух подходов к моделированию точечной сварки

/MAT/LAW59 +/FAIL/CONNECT |

/MAT/LAW 83+/FAIL/ SNCONNECT |

|||

|---|---|---|---|---|

Кривая роста |

Две кривые роста (в нормальным и сдвигом направлениями) |

Одна нормализ-нная кривые текучести с максимальным напряжением \(R_{N,} R_{S}\) |

||

Максимум стресс в комбинированный тест режима |

комбинированный

|

учитывать нормальный и сдвиг

|

||

ванный | с :math:`a_{T},a_{N}, | |

Pasligh, N., Schilling, R., and Bulla, M., “Modeling of Rivets Using a Cohesive Approach for Crash Simulation of Vehicles in PRADIOS,” SAE Int. J. Trans. Safety 5(2):2017, doi:10.4271/2017-01-1472

Моделирование болтов для столкновений

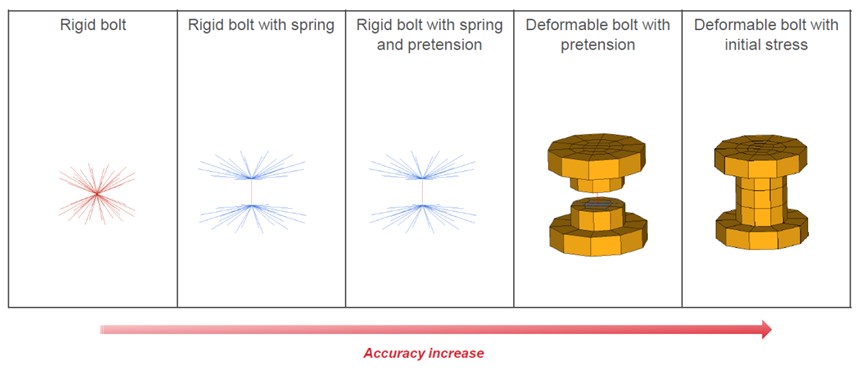

Существуют различные способы моделирования болтовых соединений и более подробная точность модели результатов:

Жесткий болт

Жесткий болт с пружиной (и предварительным натяжением)

Деформируемый болт с пружиной и предварительным натяжением

Деформируемый болт с начальным напряжением

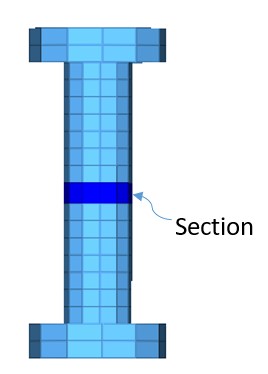

Рисунок 293: Методы моделирования болтов

Жесткий болт

Использование одного жесткого тела (/RBODY), соединенного с деталями, к которым прикреплен болт, является самым простым методом. Хотя этот метод очень стабилен

и прост в моделировании, вы не можете учитывать предварительное натяжение, упругопластичность

и поведение при разрыве для болта, а выходная сила отсутствует, и моделировать прохождение головки болта через отверстие невозможно.

- Рисунок 294: Метод моделирования жесткого болта

Примечание: Основной узел должен быть свободным.

Примечание: Основной узел должен быть свободным.

Жесткий болт с пружиной (и предварительным натяжением)

Используйте два жестких тела (/RBODY), соединенных с каждым набором деталей, которые

связаны с болтом, а затем установите один пружинный элемент

(/PROP/SPR_BEAM) между обоими жесткими телами. С помощью этого метода

можно описать упругопластическое поведение разрыва в

любом направлении, а силу, проходящую через болт (нормальная сила,

усилие сдвига, моменты), можно вывести, используя /TH/SPRING. Этот метод

часто используется при анализе автомобильных столкновений, но он имеет ограниченные

возможности для моделирования предварительного натяжения.

Рисунок 295: Жесткий болт с пружиной

Примечание:

Основной узел должен быть свободным.

TПружинный элемент прикреплен к жестким телам в качестве вторичного узла.

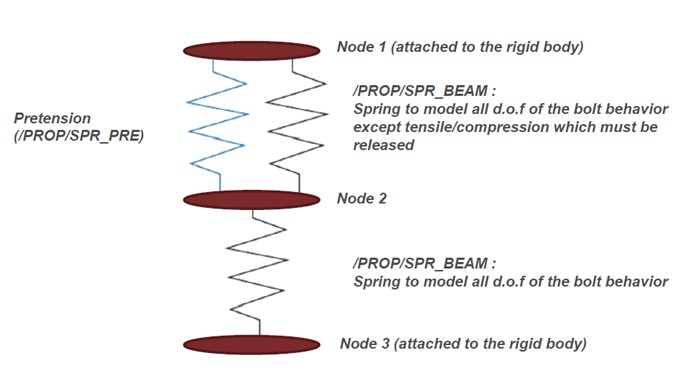

Для описания предварительного натяжения с помощью этого метода необходимо добавить еще два пружинных элемента

(/PROP/SPR_PRE и /PROP/SPR_BEAM). /IMPDISP или

/CLOAD можно использовать для имитации предварительной нагрузки. Состояние автобаланса

рассчитывается PRADIOS.

Рисунок 296: Моделирование предварительного натяжения с помощью пружин

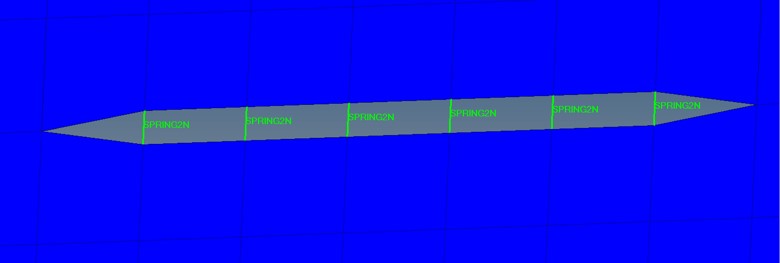

Деформируемый болт с пружиной и предварительным натяжением

Сетчатый болт с твердыми элементами (/BRICK или любой другой тип твердого элемента) и разрезом посередине.

Два твердых тела, соединенных с каждой стороной сетчатого болта и пружинного ряда (две пружины с /PROP/SPR_BEAM и одна пружина с

/PROP/SPR_PRE), как указано выше, между твердыми телами используются для описания предварительного натяжения.

С помощью этой более подробной модели головка болта, проходящая через отверстие, может быть рассмотрена в моделировании.

Рисунок 296: Моделирование предварительного натяжения с помощью пружин

Деформируемый болт с пружиной и предварительным натяжением

Сетчатый болт с твердыми элементами (/BRICK или любой другой тип твердого элемента) и разрезом посередине.

Два твердых тела, соединенных с каждой стороной сетчатого болта и пружинного ряда (две пружины с /PROP/SPR_BEAM и одна пружина с

/PROP/SPR_PRE), как указано выше, между твердыми телами используются для описания предварительного натяжения. С помощью этой более

подробной модели головка болта, проходящая через отверстие, может быть рассмотрена в моделировании.

Рисунок 298: Полностью сетчатый деформируемый болт

Примечание:

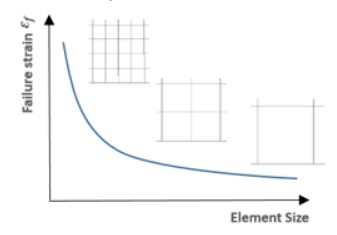

Точность определения разрыва и напряжения зависит от размера ячейки.

SСила сжатия в болте необходима для измерения сил, проходящих через отверстие.

Кинематические ограничения

В PRADIOS кинематическое условие — это узловое ограничение, применяемое к набору узлов.

Существует несколько различных типов узловых ограничений:

Жесткая стена

Жесткое тело

Граничные условия

Связанный интерфейс

Цилиндрическое соединение

Жесткое звено

Соединение зубчатого типа

Численные методы, доступные в PRADIOS, которые применяются к кинематическим условиям:

: Метод штрафа: Жесткие стенки

: Основное вторичное кинематическое условие: Интерфейс TYPE2, жесткое тело

: Локальное кинематическое условие: Жесткое звено, цилиндрическое соединение

: Множитель Лагранжа: Старые и новые интерфейсы, жесткая стена, жесткое тело и т. д.

Жесткое тело (/RBODY)

Жесткое тело определяется набором вторичных узлов и главным узлом. Его можно сравнить с деталью с бесконечной жесткостью. Между вторичными узлами не допускается относительное смещение, а общее движение жесткого тела управляет главным узлом.

Поскольку кинематическое условие применяется к каждому вторичному узлу и для всех направлений, никакие другие узловые ограничения не допускаются. Однако в случае метода множителей Лагранжа решение может быть найдено, если не применяются несовместимые кинематические условия.

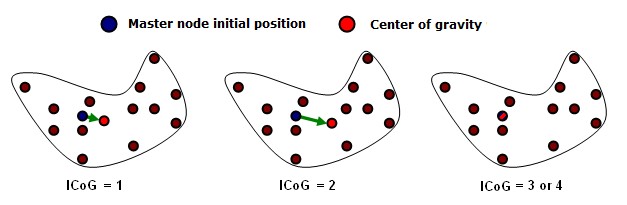

Доступны четыре варианта для позиционирования центра тяжести жесткого тела:

- Case 1

Центр тяжести вычисляется с учетом массы и координат вторичных и основных узлов. Масса твердого тела представляет собой сумму добавленной массы и массы вторичных узлов.

- Case 2

COG вычисляется только с учетом массы и координат вторичных узлов. Масса твердого тела представляет собой сумму добавленной массы и массы вторичных узлов.

- Case 3

COG устанавливается в координатах главного узла

- Case 4

Масса твердого тела равна сумме добавленной массы и массы вторичного узла. Центр тяжести задается в координатах основного узла. Масса твердого тела равна добавленной массе.

Настоятельно рекомендуется использовать искусственный узел (не являющийся частью элемента) в качестве основного узла, поскольку PRADIOS Starter, скорее всего, переместит основной узел. Основной узел перемещается PRADIOS Starter в центр тяжести; если только флаг ICoG не установлен на 3 или 4. Рекомендуется установить ICoG на 2, чтобы получить наиболее реалистичное поведение; затем центр тяжести вычисляется с учетом только вторичных узлов. Если ICoG установлен на 1, основной узел с собственной массой включается для вычисления центра тяжести.

Если основной узел изначально установлен в центр тяжести, поведение с использованием ICoG = 1 или 2 аналогично.

Рисунок 299: Вычисление центра тяжести

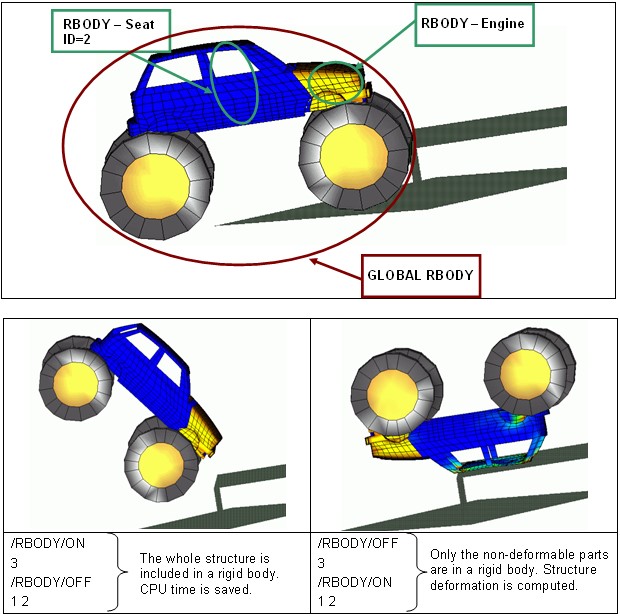

В моделировании автокатастрофы в основном используются жесткие тела, и можно выделить три типичных варианта использования жестких тел:

Жесткое тело, покрывающее часть модели конечных элементов, включая оболочки, твердые тела или другие элементы: в этом случае масса вторичных узлов дает общую массу жесткого тела, и дополнительная масса не требуется. Главный узел может быть расположен где угодно, и он будет перемещен в центр масс. Этот тип жесткого тела экономит большое количество процессорного времени.

Жесткое тело, представляющее немоделируемый компонент, соединенный с некоторыми структурными узлами: в этом случае для соединения жесткого тела с моделью конечных элементов используется только несколько вторичных узлов. Масса и инерция добавляются, а главный узел располагается в центре масс компонента. Главный узел будет двигаться лишь немного, учитывая массу вторичных узлов. В некоторых случаях фиктивная сетка используется для визуализации жесткого тела или для моделирования контактов, но если фиктивные элементы имеют небольшую массу, предыдущие замечания по-прежнему верны.

Жесткое тело, используемое для соединения двух или более частей вместе: для этих жестких тел не требуется дополнительная масса, а главный узел может быть расположен где угодно. Для этих жестких тел необходимо использовать сферическую инерцию; поскольку эти жесткие тела обычно очень малы (от 4 до 8 узлов), инерция часто очень мала в одном направлении и очень велика для одного конкретного направления. Это может привести к нестабильности; поэтому, благодаря использованию сферической инерции, инерция будет одинаковой для любого направления.

Активация/Деактивация

Твердые тела можно активировать или деактивировать с помощью /SENSOR или с помощью

параметров движка /RBODY/ON или /RBODY/OFF.

Чтобы активировать два твердых тела с помощью главного узла 1 и 2, добавьте

следующую опцию в Rootname_0001.rad:

- /RBODY/ON

1 2

Все элементы, входящие в состав обоих жестких тел, деактивированы.Все элементы, входящие в состав обоих жестких тел, деактивированы. Чтобы деактивировать одно твердое тело, идентификатор основного узла которого равен 3, добавьте:

- /RBODY/OFF

3

Все элементы реактивированы, деформации и напряжения соответствуют значениям, оставшимся со времени предыдущей дезактивации.

Движения твердого тела

Одно из основных применений активации и деактивации твердого тела касается движений опрокидывания, как при моделировании опрокидывания. Во время свободного полета автомобиля деформацией элементов можно пренебречь. Значительную часть времени ЦП можно сэкономить, если всю конструкцию заменить временным жестким телом во время полета. Перед ударом о землю это твердое тело деактивируется и в конечном итоге снова активируется после отскока.

Двигатель

Рисунок 300: Активация - деактивация твердых тел в примере опрокидывания

Начальное статическое равновесие

Другое применение активации и деактивации жесткого тела - для начального статического равновесия, где применяется только сила тяжести. При анализе краш-теста может быть интересно установить весь автомобиль в равновесии над подвеской, а манекен - на сиденье. Для явного анализа требуется много времени, чтобы достичь статического равновесия; следовательно, использование большого твердого тела позволяет быстрее получить решение. Однако в этом случае деформация в автомобиле или манекене под действием силы тяжести игнорируется, и за обоснованностью этого предположения необходимо тщательно следить.

Рисунок 301: Примеры статического равновесия

Объединение жестких тел

Опция /MERGE/RBODY может использоваться для объединения жестких тел вместе или

добавления вторичных узлов к существующему жесткому телу. Вторичные

сущности,

определенные, становятся вторичными по отношению к основному жесткому телу. Вторичные

сущности могут быть жесткими телами, отдельными узлами или наборами узлов. Несколько вторичных

сущностей могут быть объединены в одно основное жесткое тело путем определения нескольких

строк в /MERGE/RBODY.

Некоторые варианты использования включают объединение двух разных сборок, определенных в

двух отдельных включаемых файлах, путем определения объединения в основном

входном файле. Это также может быть полезно, когда отдельные части, определенные как жесткие,

необходимо объединить в одно жесткое тело для моделирования сложного компонента,

например, двигателя.

Основное твердое тело, определенное в /MERGE/RBODY, может быть определено как

вторичное твердое тело в другом

/MERGE/RBODY. Однако следует избегать сложных иерархий, поскольку их

может быть трудно отладить. Вторичные сущности могут быть

определены только в одном /MERGE/RBODY, а не в любом /RBODY; в противном случае

возникают несовместимые кинематические условия.

Перед объединением инерция, масса и центр тяжести каждого

вторичного и основного твердого тела рассчитываются на основе их свойств /RBODY. Затем вторичные сущности объединяются с основным твердым телом, и новые свойства твердого тела рассчитываются на основе опции /MERGE/RBODY Iflag.

Жесткая стена (/RWALL)

Жесткая стена — это узловое ограничение, применяемое к набору вторичных узлов, чтобы избежать проникновения узла в стену. Если контакт обнаружен, то ускорение и скорость вторичного узла изменяются.

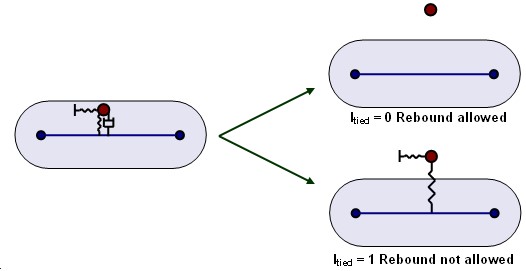

Нет зазора, чтобы определить, находится ли вторичный узел в контакте. Контакт происходит только тогда, когда вторичный узел соприкасается с жесткой поверхностью стены. Тангенциальная скорость вторичного узла также может изменяться в зависимости от флага Скольжение. Значение по умолчанию (=0) включает чистое скольжение модели во время контакта. Если установлено значение 1, скольжение не допускается, вторичные узлы «связаны» в тангенциальном направлении. Если установлено значение 2, включается трение на основе модели Кулона.

В PRADIOS доступны четыре типа жестких стен:

Бесконечная жесткая стена

Бесконечная цилиндрическая стена

Сферическая стена

Конечная плоская стена

Жесткие стены могут быть фиксированными или подвижными. Фиксированная стена — это чистое кинематическое условие для всех затронутых узлов; тогда как подвижная стена похожа на основной вторичный вариант. Основной узел определяет положение стены на каждом временном шаге и накладывает скорость на затронутые вторичные узлы. Силы затронутого вторичного узла применяются к основному узлу. Силы вторичного узла вычисляются с сохранением импульса. Масса вторичного узла не передается на основной узел, предполагая большую массу жесткой стены по сравнению с массой затронутых вторичных узлов.

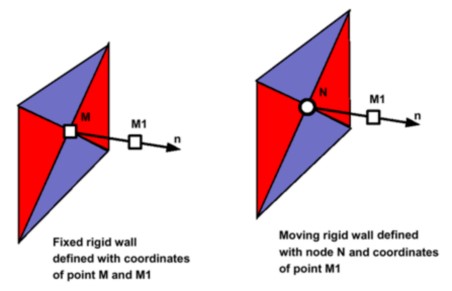

Бесконечная жесткая стена

Бесконечная жесткая стена — это плоская поверхность, которая простирается до бесконечности. Она определяется двумя точками, представляющими нормаль жесткой стены (рисунок 302).

Рисунок 302: Бесконечная жесткая стена

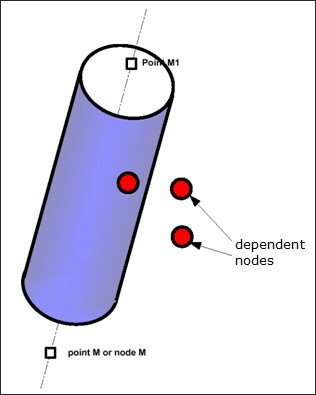

Бесконечная цилиндрическая стена

Бесконечная цилиндрическая стена — это цилиндр, который простирается до бесконечности. Она определяется двумя точками (или одной точкой и одним узлом) и диаметром.

Примечание: контакт возможен только снаружи цилиндрической стенки.

Рисунок 303: Бесконечная цилиндрическая стена

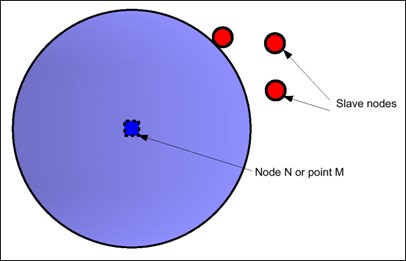

Сферическая стена

Сферическая стена — это сфера, определяемая точкой M (или узлом N) и диаметром.

Рисунок 304: Сферическая стена

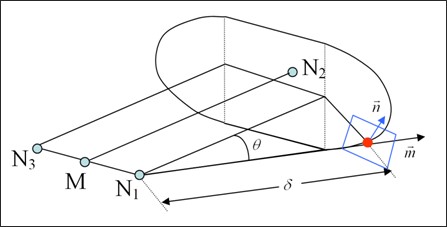

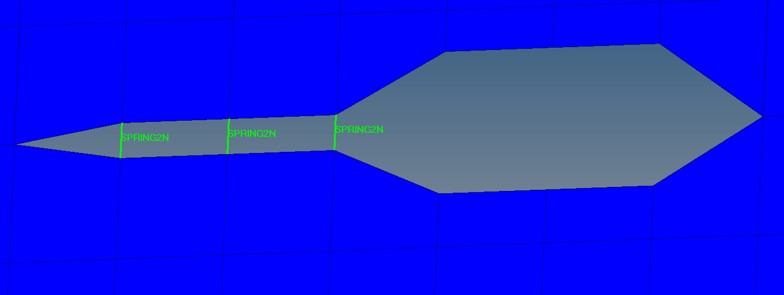

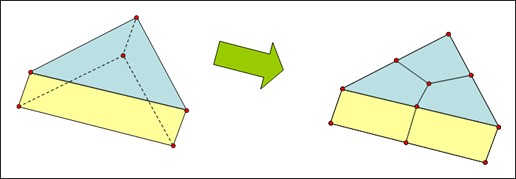

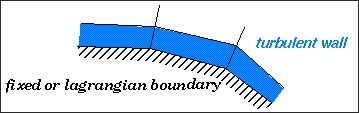

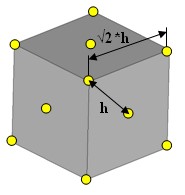

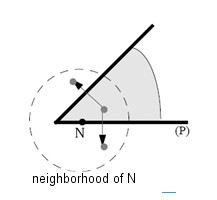

Конечная плоская стена

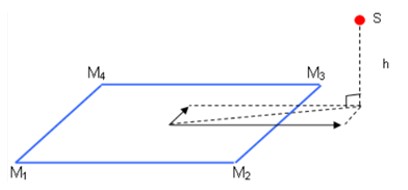

Конечная плоская стена — это параллелограмм, определяемый тремя точками M, M1 и M2. В случае движущейся стены M будет считаться основным узлом. .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image49.jpg

- width

3.09336in

- height

3.33292in

Рисунок 305: Конечная плоская жесткая стена

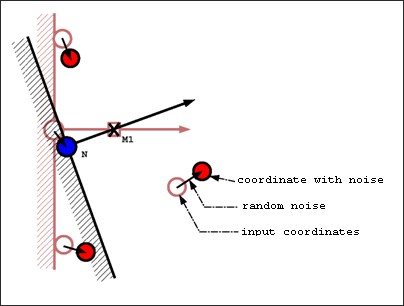

Комментарии

Во время моделирования движущаяся стена следует основному узлу N, но ориентация стены остается постоянной и параллельной исходной нормали. Движущаяся жесткая стена не соблюдает равновесие моментов, применяется только равновесие сил. Внешний момент; поэтому прикладывается из лаборатории к стене.

2.Если вторичные узлы определены только с расстоянием от стенки, то учитываются узлы с положительным или нулевым расстоянием (то есть узлы за бесконечной стеной или в стенке цилиндра не считаются вторичными).

Узел, изначально ударившийся о стену, не может отскочить; за исключением случаев, когда скорость отскока достаточно высока, чтобы выйти из стены всего за один цикл.

Если к координатам узла добавляется случайный шум, то начальное положение вторичных узлов изменяется, а для движущейся стены изменяется местоположение стены. Поэтому возможно, что некоторые вторичные узлы с нулевым или близким к нулю расстоянием от стены перемещаются внутрь стены. Если вторичные узлы определены с расстоянием, то эти узлы не являются вторичными узлами. Если эти узлы являются явными вторичными узлами, то они останутся внутри стены без возможного отскока.

При случайном шуме (/RANDOM) ориентация движущейся стены также изменяется. Местоположение главного узла N перемещается со случайным значением, а нормаль, определенная узлом N и точкой M1, изменяется. Это особенно критично, если точка M1 находится близко к точке N.

Рисунок 306: Изменение ориентации стены из-за случайного шума

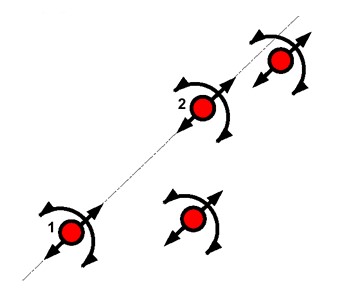

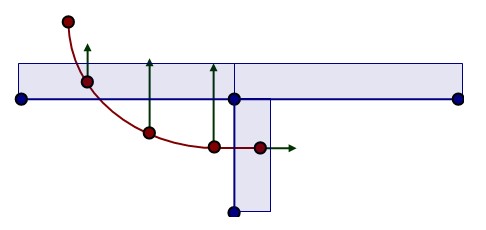

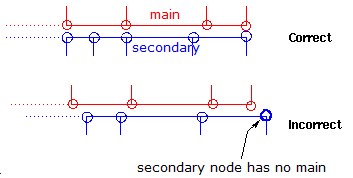

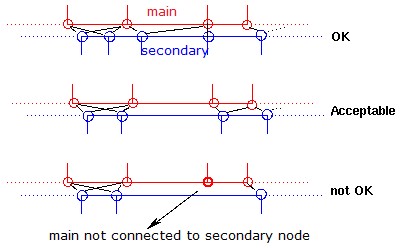

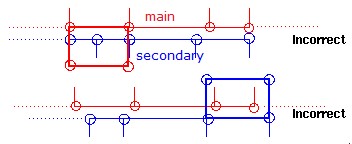

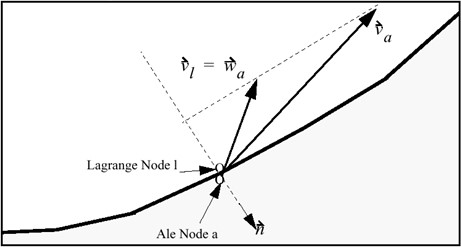

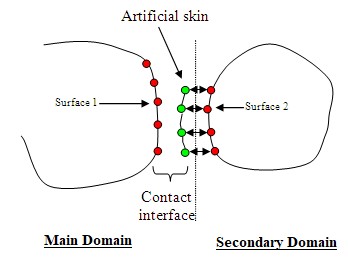

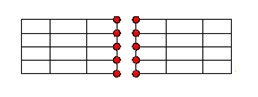

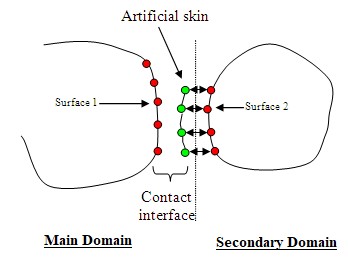

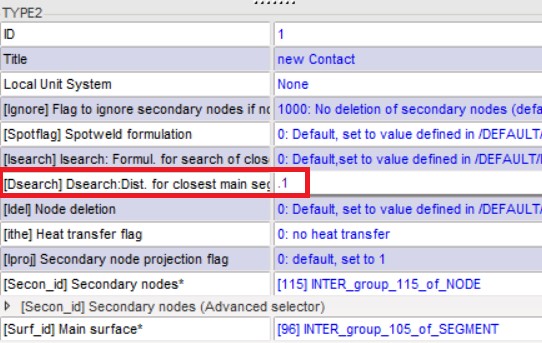

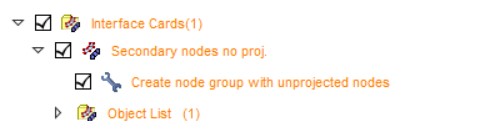

Связанный контакт (/INTER/TYPE2)

Интерфейс TYPE2, также называемый связанным интерфейсом, является узловым ограничением для жесткого соединения набора вторичных узлов с основной поверхностью. Силы и моменты вторичных узлов передаются основным узлам, а затем вторичные узлы позиционируются кинематически в соответствии с движением основных узлов.

Этот интерфейс обеспечивает полное равновесие сил и моментов.

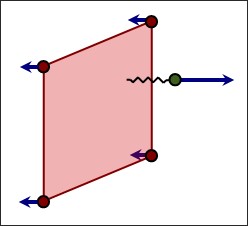

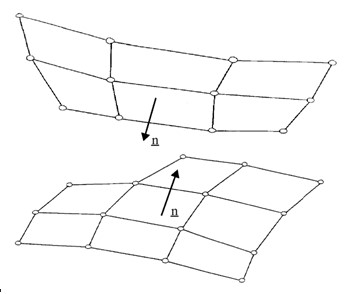

Рисунок 307: Интерфейс TYPE2 - Связанный

Для описания этого соединения доступны четыре формулировки.

Формулировка точечной сварки по умолчанию

Оптимизированная формулировка точечной сварки

Формулировка с отказом

Формулировка штрафа

Формуляция точечной сварки по умолчанию

\(Spot_{flag} =0\)

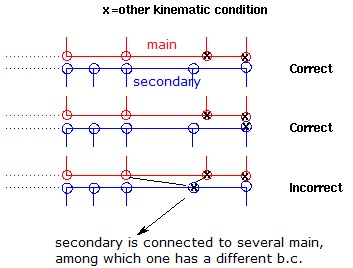

Рисунок 308:

Когда флаг установлен на 0, формулировка spotflag является формулировкой по умолчанию:

На основе функций формы элемента

Генерация песочных часов с недоинтегрированными элементами

Задание функции жесткости соединения вторичной локализации узла

Рекомендуется для полностью интегрированных оболочек (основных)

Рекомендуется для соединения вторичных узлов кирпича с основными сегментами кирпича (переход сетки без свободы вращения)

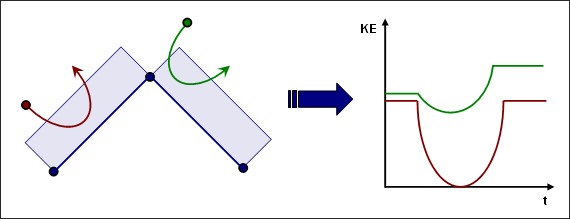

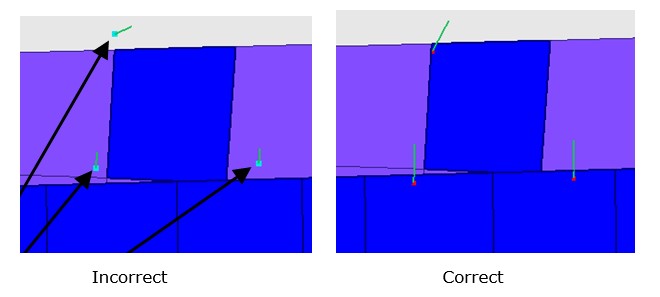

Оптимизированная формулировка точечной сварки

\(Spot_{flag} =1\)

Рисунок 309:

Когда флаг установлен на 1, формулировка spotflag является оптимизированной формулировкой:

Основана на среднем жестком движении элемента

Нет проблемы песочных часов

Постоянная жесткость соединения

Рекомендуется для недоинтегрированных оболочек (основных)

Рекомендуется для соединения балок, пружин и вторичных узлов оболочки с основными сегментами кирпича

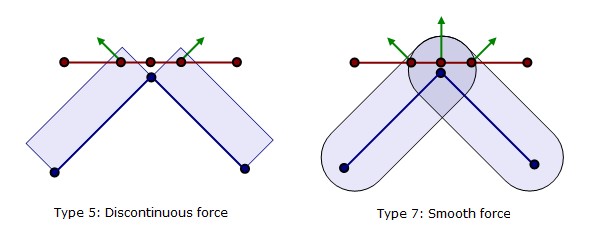

Формулировка с отказом

\(Spot_{flag}\) =20, 21 and 22

Используя эти опции, можно определить эти два критерия отказа:

Rupt= 0 (независимые параметры разрыва):

Ошибка при достижении Max_N_Dist или Max_T_Dist (по умолчанию)

Rupt= 1 (параметры связанного разрыва):

Ошибка, когда \(\sqrt{\left(\frac{N\_Dist}{Max\_N\_Dist}\right)^{2}+\left(\frac{T\_Dist}{Max\_T\_Dist}\right)^{2}}>1\)

Во время расчета вычисляются нормальное напряжение, касательное напряжение, нормальное смещение и касательное смещение, которые сравниваются с максимальными значениями, определенными в интерфейсе. Как только будут достигнуты максимальные критерии, нормальное напряжение и касательное напряжение будут установлены на 0.

Формулировка штрафа

\(Spot_{flag} = 25\)

Основная цель интерфейса TYPE2 с использованием метода штрафа — привязать вторичный узел к основному сегменту без каких-либо кинематических ограничений. Использование метода штрафа может помочь избежать

“INCOMPATIBLE KINEMATIC CONDITIONS”

|

Цилиндрическое соединение (/CYL_JOINT)

Цилиндрическое соединение похоже на твердое тело, за исключением того, что одно конкретное направление определяется первыми двумя вторичными узлами. Все узлы могут свободно перемещаться вдоль этого направления и вращаться вокруг него.

Кинетическое условие применяется ко всем вторичным узлам, включая первые два, определяющие привилегированное направление. Главный узел не используется.

Рисунок 310: Цилиндрическое соединение

Если все вторичные узлы изначально выровнены, они всегда останутся выровненными. Как показано на рисунке 310, свобода вращения — это локальное вращение для каждого узла, а не глобальное вращение вокруг оси 1-2. Поэтому рекомендуется использовать цилиндрическое соединение с выровненными узлами.

Рисунок 311: Пример дверной петли

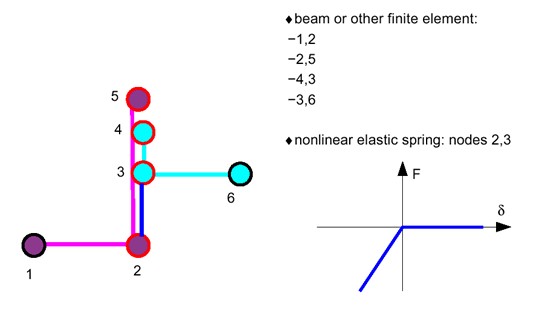

Рисунок 311 показывает, как можно смоделировать петлю с помощью цилиндрического соединения. Цилиндрическое соединение состоит из узлов 2, 5, 3 и 4. Обратите внимание, что при моделировании петли узлы должны быть выровнены, чтобы получить реалистичное вращение, затем для соединения узлов 1-2, 2-5, 4-3 и узлов 3-6 используются балки или любые другие конечные элементы. Наконец, можно связать узлы 2-3 с помощью нелинейной упругой пружины, чтобы улучшить соединение.

Рисунок 312: Моделирование шарнира

Жесткая связь (/RLINK)

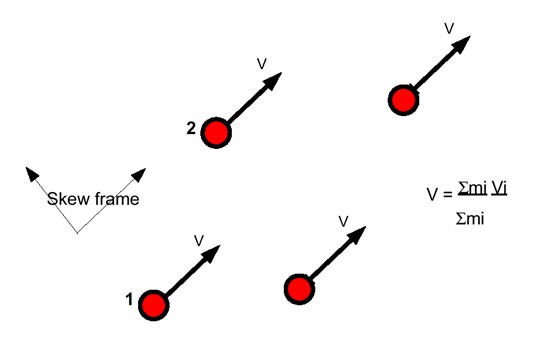

Опция жесткой связи устанавливает одинаковую скорость для всех вторичных узлов для одного или нескольких направлений. Направления определяются для наклонной или глобальной системы координат, скорость вычисляется с сохранением импульса.

Глобальное равновесие моментов не соблюдается. Жесткая связь эквивалентна бесконечной жесткой пружине TYPE8.

Note: A rigid link is a PRADIOS Engine input. A rigid link is alive only during the current restart run. For permanent rigid bodies, the input has to be repeated in each Engine input deck.

Рисунок 313: Модель жесткой связи

Многоточечные ограничения (/MPC)

Шины зубчатого типа сложнее других кинематических соединений. Они используют метод множителей Лагранжа и совместимы со всеми другими кинематическими условиями множителей Лагранжа и несовместимы со всеми классическими кинематическими условиями.

Приводятся три примера таких соединений:

Вращающееся зубчатое соединение

Реечное соединение

Соединение шестерни дифференциала

Масса и инерция могут быть добавлены ко всем узлам. Соединения MPC накладывают соотношения между скоростями узлов. MPC не может быть применен к поступательным степеням свободы узла без массы или вращательным степеням свободы узла без инерции.

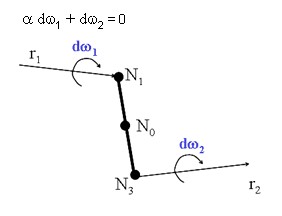

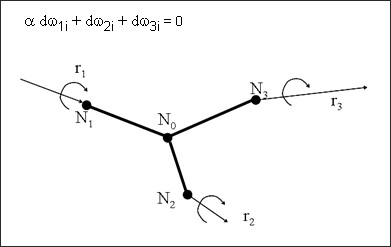

Соединение типа вращательной шестерни

Это сочленение используется для наложения соотношения вращательной скорости между входным и выходным узлом как:

Рисунок 314: Вращательное соединение

Поступательные скорости узлов зубчатого соединения ограничены жестким отношением связи. Для вращательных степеней свободы масштабный коэффициент накладывается между скоростями узлов N1 и N2, измеренными в их локальных координатах. Соответствующие уравнения ограничений:

\(d\big{(}\Delta\omega_{1}\cdot r_{1}\big{)}+\big{(}\Delta\omega_{2}\cdot r_{2}\big{)}=0\)

\(\Delta\omega_{1}\cdot s_{1}=0, \Delta\omega_{2}\cdot s_{2}=0\Delta\omega_{1}\cdot t_{1}=0, \Delta\omega_{2}\cdot t_{2}=0\)

Где, \(\Delta\omega_{1}=\omega_{1}-\omega_{0},\) \(\Delta\omega_{2}=\omega_{2}-\omega_{0}\) относительные скорости вращения узлов \(N_{1}\) и \(N_{2}\) по отношению к скорости вращения твердого тела.

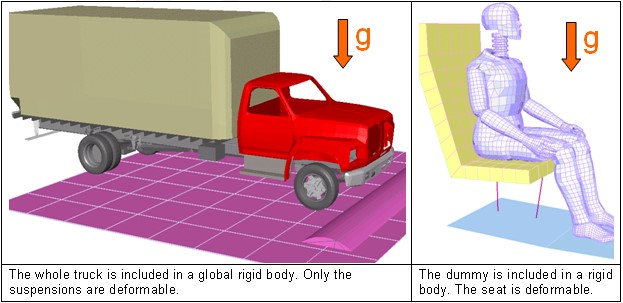

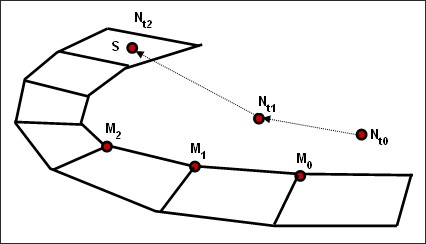

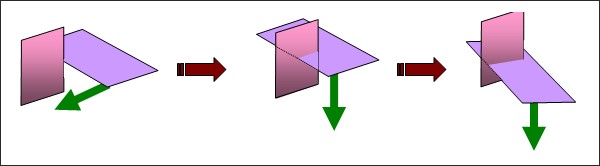

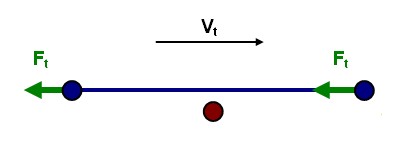

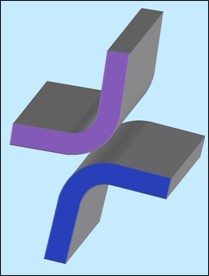

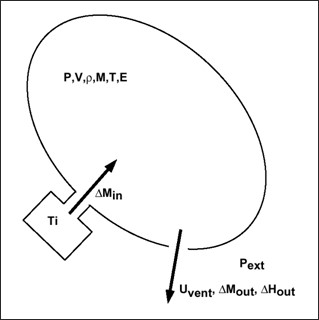

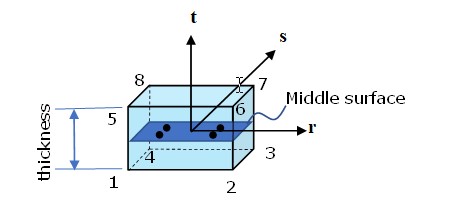

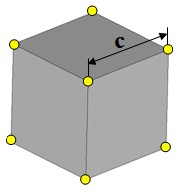

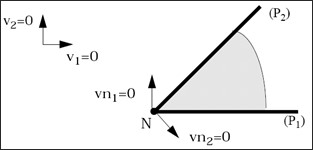

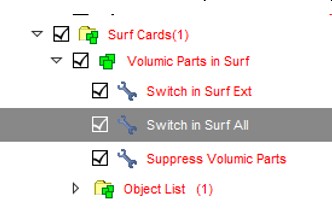

Соединение реечной передачи

Это соединение позволяет преобразовать скорость вращения узла в поступательную скорость как: .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image59.jpg

- width

3.75994in

- height

1.61437in

Рисунок 315: Сочленение типа «рейка и шестерня»

Уравнения ограничений для этих скоростей:

Дифференциальное соединение зубчатой передачи

Это соединение используется для наложения соотношений скорости вращения между входным узлом и двумя выходными узлами как:

Рисунок 316: Тип дифференциального соединения

Скорости вращения дифференциального соединения ограничиваются соотношениями:

Методы применения кинематических условий

Численные методы, доступные в PRADIOS для применения кинематических условий,

это:

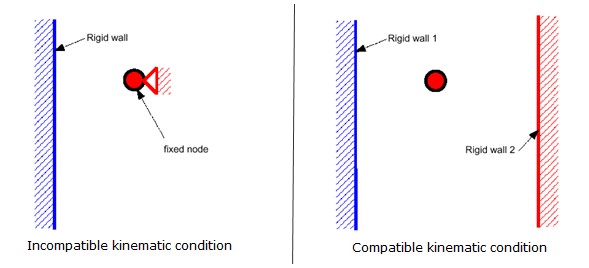

Несовместимые кинематические условия

Поскольку узловые ограничения основаны на кинематических условиях, применяемых к узловым степеням свободы, поэтому не допускается применение двух узловых ограничений к одному и тому же набору узлов, если только индуцированные кинематические условия не являются идеально ортогональными (например: граничное условие в направлении X и жесткая связь в направлении Y).

PRADIOS Starter будет выдавать следующее предупреждение каждый раз, когда два узловых ограничения применяются к одному и тому же набору узлов. +———————————————————————–+ | ПРЕДУПРЕЖДЕНИЕ ИДЕНТИФИКАТОР: 147 | | | | *** ВНИМАНИЕ: НЕСОВМЕСТИМЫЕ КИНЕМАТИЧЕСКИЕ УСЛОВИЯ | | | | 2 КИНЕМАТИЧЕСКИХ УСЛОВИЯ НА УЗЛЕ xxxxxx, | | | | В НАПРАВЛЕНИИ ПЕРЕМЕЩЕНИЯ X, ДЛЯ: | | | | - Узловое ограничение 1 (например, ГРАНИЧНОЕ УСЛОВИЕ) | | | | - Узловое ограничение 2 (например, ЖЕСТКАЯ СТЕНА) | +———————————————————————–+

Очень важно учитывать все предупреждения о несовместимых кинематических условиях. Истинно несовместимые кинематические условия (то есть узлы, принадлежащие нескольким твердым телам) могут генерировать энергию и локальную неустойчивость. В таком случае точность результатов будет серьезно снижена.

PRADIOS Starter не проверяет, действительно ли кинематические условия несовместимы. Если они строго ортогональны или если они не применяются одновременно, просто игнорируйте предупреждение. На рисунке 317 показаны два случая: в первом случае узел является вторичным на жесткой стенке и имеет граничное условие в неортогональном направлении. Если жесткая стенка закреплена, то возможных несовместимых условий нет (узел не может удариться о стену). Если стена движется, то невозможно после удара соблюдать оба условия. Поэтому граничное условие не применяется, а силы реакции на стене неверны. Во втором случае узел определяется как вторичный для двух параллельных стенок. Если две жесткие стены зафиксированы, то нет возможных несовместимых условий, поскольку узел не может воздействовать на две стены одновременно. Если одна стена движется, это не приводит к проблемам, пока движущаяся стена не пересекает фиксированную стену.

Рисунок 317: Предупреждение PRADIOS о кинематических условиях

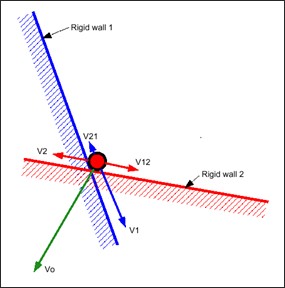

В многопроцессорной версии PRADIOS запуск, выполненный дважды, может дать

разные результаты, если некоторые кинематические условия несовместимы. Это все еще верно, если используется опция /PARITH/ON. Например, если

вторичный узел воздействует на две неортогональные жесткие стенки, как показано на

Рисунок 318, результаты, полученные на многопроцессорном компьютере, могут быть произвольными.

Если жесткая стенка 1 вычисляется до жесткой стенки 2, скорость V0 заменяется

скоростью V12. Если жесткая стенка 2 вычисляется до жесткой стенки 1,

скорость V0 становится V21. На многопроцессорных компьютерах порядок, в котором применяются жесткие стенки и другие кинематические условия,

произвольный и может быть изменен от одного цикла к другому и от одного запуска

к другому.

Рисунок 318: Произвольные результаты с несовместимыми кинематическими условиями

Метод множителей Лагранжа позволяет применять несколько узловых ограничений к одному и тому же набору узлов, поскольку он решает глобальную систему уравнений со всеми ограничениями множителей Лагранжа. Однако не допускается смешивать оба метода для одного и того же набора узлов. Тем не менее, оба метода можно успешно использовать в модели, если они применяются к разным узлам.

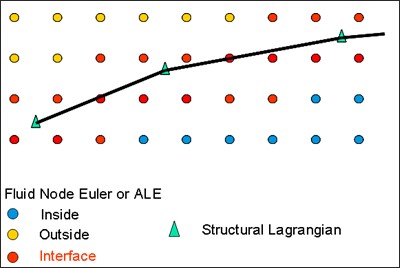

В PRADIOS доступно несколько интерфейсов, в этом разделе рассматриваются только контактные интерфейсы. Каждый интерфейс отличается номером типа.

Интерфейс TYPE2 — это кинематическое условие, используемое для соединения двух сеток Лагранжа, и в этом разделе не описывается подробно (см. Кинематические ограничения). Краткий обзор контактных интерфейсов показан в Таблице 21.

Каждый из этих интерфейсов был разработан для определенной области применения, но эта область — не единственный критерий выбора. Некоторые ограничения различных алгоритмов, используемых в каждом интерфейсе, также могут определить ваш выбор.

Ограничения алгоритма в основном касаются поиска затронутого сегмента. Этот поиск можно выполнить напрямую (интерфейс TYPE7, TYPE10 и TYPE11) или через поиск ближайшего узла (другие типы интерфейсов). Поиск ближайшего узла выполняется с помощью дешевого, но ограниченного алгоритма (интерфейс TYPE3, TYPE5 и TYPE6).

Интерфейсы TYPE3, TYPE5 и TYPE6 также имеют некоторые ограничения, касающиеся выбора между сегментами, подключенными к ближайшему узлу. Нормальная ориентация является одним из ограничений для этих интерфейсов.

Интерфейс TYPE23 определяет контактный интерфейс для тканей подушек безопасности. Это мягкий штрафной контакт, который может иметь дело с проникновением и пересечением, часто возникающими в сложенной сетке подушки безопасности.

Интерфейс TYPE24 использует постоянную штрафную жесткость, и поэтому временной шаг не влияет.

Тепловое трение можно вычислить с помощью интерфейсов TYPE7 и TYPE21.

Таблица 21: Интерфейсы в PRADIOS

Тип |

Описание |

Приложение |

**Контакт Уход ** |

|---|---|---|---|

1 / 9 |

ALE/LAG с скользящий |

Fluid-structure взаимодействие |

Основное- Вторичное |

2 |

Связанный интерфейс |

Изменение сетки density (твердый) |

Основное- Вторичное или LM |

Воздействие | использовать | Штраф |

Воздействие | Пользовательский| Штраф |

7 |

Общий цель Контакт Воздей- ствие между двумя частями |

на все скорости |

Штраф или LM |

8 |

Вытяжка контакт |

Штамповка приложения |

Штраф |

10 |

Как TYPE7, но привязан Контакт |

|

Штраф |

11 |

|

стержни или пружины |

|

12 |

|

|

Штраф |

16 & 17 |

Контакт между узлами в квадратный твердые тела формы и твердые оболочки или между квад- ратные формы |

Сетки с 8-узловой или 16узлов толстостенный или 20 кирпичей |

LM |

18 |

CEL Лагранж / Эйлер интерфейс |

взаимодействия |

Штраф |

19 |

Сочетание интерфейс TYPE7 и TYPE11 |

|

Штраф |

21 |

Специфический интерфейс между недеформируемый основная поверхность и вторичный поверхность |

Для штамповки |

Основной-Вторичный |

23 |

мягкий Штраф Контакт |

|

мягкий Штраф |

24 |

общий контакт интерфейс, необязательный одинарная по- верхность или поверхность поверхность или узлы для поверхность контактов |

этот контакт интерфейс может заменить интерфейс TYPE3, 5, 7 |

Штраф жесткость константу и; следовательно, шаг по времени не затронуто |

Обработка контакта

Существует два подхода, которые работают с контактом:

Метод штрафа чаще всего используется в явных кодах и может быть найден в большинстве интерфейсов PRADIOS

Метод множителей Лагранжа (

/LAGMULи/INTER/LAGMUL) используется в специальных исследованиях случаев

Метод штрафа

Интерфейсы, использующие метод штрафа, основаны на основной/вторичной обработке. Контакт может происходить только между набором вторичных узлов и набором основных сегментов. Основные сегменты определяются в зависимости от типа элемента, на котором они лежат. Если это 3-узловая или 4-узловая оболочка, сегмент является поверхностью элемента. Если это сплошной элемент, сегмент определяется как грань. Наконец, если это 2D-сплошной элемент (квадрат), сегмент является стороной.

Рисунок 319: Определение сегмента

Расстояние зазора определяется для определения того, находится ли узел в контакте с сегментом.

Рисунок 320: Зазор и проникновение

Как только узел проникает в зазор, упругая пружина добавляется между вторичным узлом и основным сегментом. Поэтому сила сопротивления будет стремиться отклонить вторичный узел.

Рисунок 321: Сила реакции в интерфейсе

На временной шаг может влиять жесткость интерфейса. Во время проникновения, поскольку пружина соединена с вторичным узлом, жесткость пружины должна быть добавлена к общей жесткости, действующей на узел (жесткость от всех элементов, соединенных с этим узлом). Узловой временной шаг должен быть уменьшен для учета жесткости пружины.

Контакт заканчивается, когда проникший узел полностью выталкивается из зазора. Таким образом, упругая пружина и сила реакции удаляются.

Стоит отметить, что контактные интерфейсы с методом штрафа полностью совместимы со всеми кинематическими условиями (например, жесткое тело, приложенная скорость и т. д.).

Метод множителей Лагранжа(/LAGMUL and /INTER/LAGMUL)

В отличие от метода штрафа, метод множителей Лагранжа является чисто математическим и не требует физических элементов (пружин) для моделирования контакта. Нелинейная система уравнений решается для учета контактных условий. Поэтому нет коллапса временного шага из-за высокой жесткости интерфейса, но требуется больше времени ЦП для выполнения одного цикла, так как новые уравнения должны быть решены нелинейным решателем. Метод имеет преимущество в остановке вторичных узлов на контактной поверхности (условие контакта точно выполняется); однако трение не может быть вычислено.

Симметричный интерфейс (/INTER/TYPE3)

Этот интерфейс используется для моделирования симметричных ударов между двумя поверхностями.

Обе поверхности определяются с помощью использования ориентированных сегментов; поэтому контакты могут происходить только с одной стороны. Каждый узел на обеих поверхностях рассматривается как вторичный узел, а каждая поверхность рассматривается как основной сегмент.

Рисунок 322: Интерфейс TYPE3

В отличие от интерфейса TYPE5, интерфейс TYPE3 имеет две основные поверхности; поэтому алгоритм контакта выполняется дважды. Первый проход решает проникновение узлов с первой поверхности относительно второй поверхности. Второй проход решает проникновение узлов со второй поверхности относительно первой поверхности. Это приводит к более высокой точности по сравнению с интерфейсом TYPE5, но требуется больше времени ЦП.

При обнаружении контакта добавляется упругая пружина, и жесткость пружины рассчитывается с использованием жесткости обеих поверхностей. На основе материальных и геометрических свойств жесткость приписывается каждой поверхности, затем вычисляется общая жесткость интерфейса:

Значение по умолчанию для масштабного коэффициента(ов) жесткости равно 0,2, по соображениям устойчивости это значение не следует изменять. Однако, если соотношение \(K_{1}\) к \(K_{2}\) больше 100 (или меньше 0,01), рекомендуется увеличить масштабный коэффициент жесткости, чтобы избежать слишком многочисленных проникновений. Жесткость пружины постоянна, что позволяет вторичным узлам проходить через среднюю плоскость основного сегмента.

Этот интерфейс не позволяет выполнять моделирование автоконтакта, поскольку узел не может принадлежать обеим поверхностям.

|

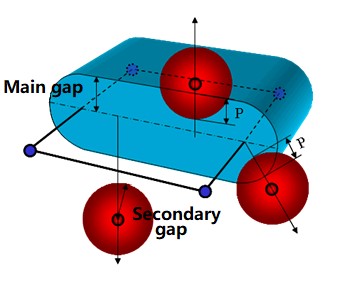

Несимметричный интерфейс (/INTER/TYPE5)

Этот интерфейс используется для моделирования ударов между основной поверхностью и списком вторичных узлов.

Интерфейс ориентирован; поэтому контакт может происходить только с одной стороны основных сегментов. Таким образом, нормаль основных сегментов должна быть ориентирована к вторичным узлам.

Рисунок 323: Интерфейс TYPE5

Основная сетка поверхности должна быть регулярной с хорошим соотношением сторон. Не допускается размещение вторичного узла на основной поверхности. Он работает только с основными сегментами, соединенными с твердыми или оболочечными элементами. Одним из вариантов использования этого интерфейса является замена жесткой стенки. Замена жесткой стенки на интерфейс TYPE5 позволит вам моделировать удары жесткого тела.

С интерфейсом TYPE5 зазор используется для определения контакта между узлом и поверхностью. Этот зазор определяется пользователем и расположен на стороне, нормальной к поверхности. Рекомендуется использовать небольшой или нулевой зазор.

При обнаружении контакта добавляется упругая пружина, и жесткость пружины рассчитывается с использованием только материальных и геометрических свойств основного сегмента. В целях обеспечения устойчивости к жесткости основной стороны применяется масштабный коэффициент жесткости 0,2. Настоятельно рекомендуется не изменять этот коэффициент, если только основная сторона не очень мягкая по сравнению с второстепенной стороной. В этом случае рекомендуется использовать отношение большего модуля упругости к меньшему в качестве масштабного коэффициента жесткости.

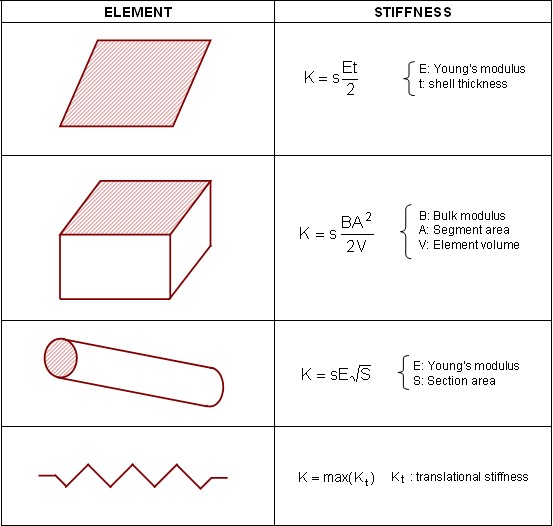

Как упоминалось ранее, жесткость зависит от геометрических и материальных свойств, а также от типа элемента. На рисунке 324 описывается способ расчета жесткости в соответствии с типом элемента, к которому прикреплен сегмент. В случае, если сегмент является общим для кирпича и оболочки (например: 3D-деталь, покрытая оболочкой), используется жесткость, связанная с элементом оболочки.

Рисунок 324: Жесткость в интерфейсе TYPE5

Главный недостаток интерфейса TYPE5 заключается в том, что контакт не может происходить с обеих сторон основного сегмента. Для проблемы с большими поворотами (обычно это происходит при анализе столкновений) контакт, скорее всего, произойдет с неправильной стороны поверхности; поэтому проникновение не будет обнаружено. Следовательно, для сложной проблемы контакта необходимо хорошее понимание удара до моделирования, чтобы правильно определить нормальные поверхности.

Другой важный недостаток заключается в том, что узел не может быть вторичным узлом и частью основного сегмента. Поэтому автоконтакт не может быть смоделирован с использованием интерфейса TYPE5.

Распространенные проблемы в интерфейсах TYPE3 и TYPE5

Интерфейсы TYPE3 и TYPE5 имеют некоторые общие проблемы.

Скачки энергии

Плохая обработка контактов

Ограниченный алгоритм поиска

Скачки энергии

Зазор, используемый в интерфейсе TYPE5 (и TYPE3), является односторонним и не учитывает края. Это может привести к скачкам энергии в случаях большого зазора (рисунок 325).

Рисунок 325: Скачок энергии

Плохая обработка контакта

Более того, поскольку жесткость интерфейса постоянна, допускается проникновение узла. Эта точка может привести к огромной ошибке, особенно если скольжение происходит во время проникновения. Рисунок 326 иллюстрирует, как вторичные узлы могут проходить через середину поверхности оболочки из-за плохой обработки контакта.

Рисунок 326: Обработка плохого контакта

Ограниченный алгоритм поиска

С интерфейсом TYPE5 (и TYPE3) обнаружение ближайшего основного узла ограничено сегментами, топологически близкими к предыдущему (топологически ограниченный алгоритм поиска). Первый поиск выполняется PRADIOS Starter для определения ближайшего начального основного узла, затем Engine определяет ближайший основной узел, принимая во внимание только сегменты, топологически близкие к предыдущему. Этот метод довольно медленный по времени ЦП, и он не очень хорошо работает, особенно если задействованы высокие кривизны (Рисунок 327).

Рисунок 327: Плохое обнаружение ближайшего основного сегмента

Интерфейс TYPE6 (/INTER/TYPE6)

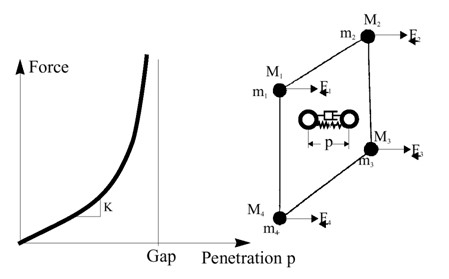

Интерфейс TYPE6 используется для моделирования контакта между двумя твердыми телами.

Этот интерфейс похож на интерфейс TYPE3, за исключением жесткости. Взаимосвязь между контактной силой и проникновением обеспечивается определяемой пользователем функцией. Этот интерфейс используется, в частности, в моделировании пассажиров транспортных средств, например: коленных буферов. Основное ограничение этого интерфейса заключается в том, что поверхность 1 должна быть частью одного твердого тела, а также для поверхности 2. Более того, обе поверхности должны быть ориентированы так, чтобы нормали были обращены друг к другу.

Используемая жесткость соответствует кривой Сила против Проникновения, введенной вами. Мгновенная жесткость интерфейса представляет собой наклон входной кривой при заданном проникновении; поэтому временной шаг может быть влиян, поскольку жесткость интерфейса используется для вычисления стабильного временного шага:

Где,

\(M\) The min (Масса первого твердого тела и Масса второго твердого тела)

\(K\) Наклон кривой силы против проникновения

Рисунок 328: Интерфейс TYPE6 — Нормальная ориентация

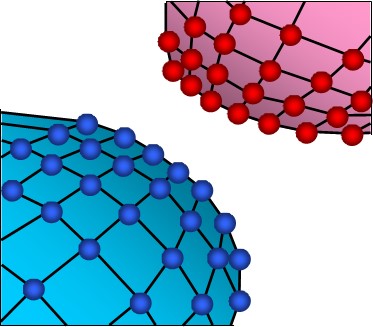

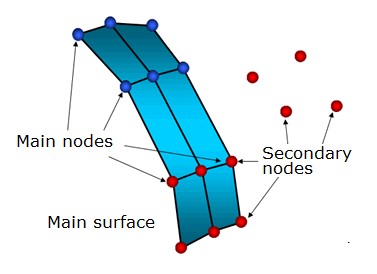

Интерфейс общего назначения (/INTER/TYPE7)

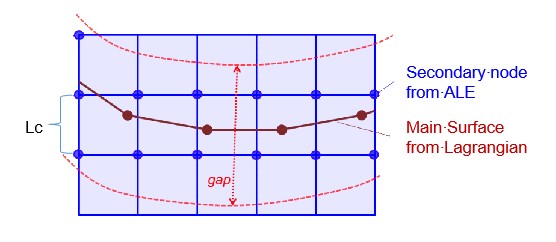

Интерфейс TYPE7 — это интерфейс общего назначения, который может имитировать все типы удара между набором узлов и основной поверхностью. В отличие от интерфейсов TYPE3 и TYPE5, интерфейс TYPE7 не ориентирован, и вторичные узлы могут принадлежать основной поверхности. Поэтому этот интерфейс может имитировать самоудар, особенно выпучивание при столкновении на высокой скорости.

Рисунок 329: Интерфейс TYPE7

Интерфейс TYPE7 решает все проблемы и ограничения, возникающие с интерфейсом TYPE3 и TYPE5. Поиск ближайшего сегмента выполняется с помощью алгоритма прямого поиска; поэтому ограничений поиска нет, и находятся все возможные контакты. Скачки энергии, вызванные узлом, ударяющимся о края оболочки, устраняются использованием цилиндрического зазора вокруг краев.

Наконец, главное преимущество интерфейса TYPE7 заключается в том, что жесткость не является постоянной и увеличивается с проникновением, предотвращая прохождение узла через середину поверхности оболочки. Это решает многие проблемы с плохим контактом (распространенные при использовании интерфейса TYPE3 или TYPE5).

Зазор, используемый в интерфейсе TYPE7, довольно сильно отличается от зазоров предыдущих интерфейсов. Зазор используется по обе стороны от средней поверхности оболочки, а вокруг краев добавляется цилиндрический зазор (рисунок 330). Зазор используется по обе стороны от средней поверхности оболочки, а вокруг краев добавляется цилиндрический зазор.

Рисунок 330: Зазор в интерфейсе TYPE7

Цилиндрический зазор позволяет избавиться от скачков энергии, узлы, воздействующие с краев, следуют по тому же пути при проникновении и выходе. Более того, такой зазор сохраняет силу реакции плавной при скольжении между сегментами.

Рисунок 331: Скольжение между сегментами

В отличие от интерфейса TYPE3 и TYPE5, переменный зазор в пространстве доступен. В зависимости от опции \(I_{gap}\), переменный зазор вычисляется для каждого удара как сумма основного зазора элемента (gm) и зазора вторичного узла (gs).

Если \(I_{gap}\) =1, переменный зазор вычисляется как: .. math:: maxBigl{[}Gap_{min},Bigl{(}g_{s}+g_{m}Bigr{)}Bigr{]}tag{216}

Если \(I_{gap}\) =2, переменный зазор вычисляется как:

Если \(I_{gap}\) =3, переменный зазор вычисляется как:

Таблица 22: Расчет переменного зазора

Элемент |

главный Элемент Зазор

|

**Вторичный узел Зазор** gs |

|---|---|---|

ОБОЛОЧКА |

\(g_{m}=\frac{t} {2}\) t: толщина главног осегмента |

\(g_{s}=\frac{t} {2}\) t: наибольшая толщина оболочка эелемента подключен к sвторичному узлу |

брусок |

gm = 0 |

gm = 0 |

ФЕРМА и БАЛКА |

Неприменимо |

\(g_{s}=\frac{1} {2}\sqrt{S}\) S: поперечное сечение |

Если также используется минимальный зазор для активации удара (\(Gap_{min}\)), то вычисленный переменный зазор не может быть меньше минимального значения. Также можно применить масштабный коэффициент к зазору и определить максимальное значение зазора.

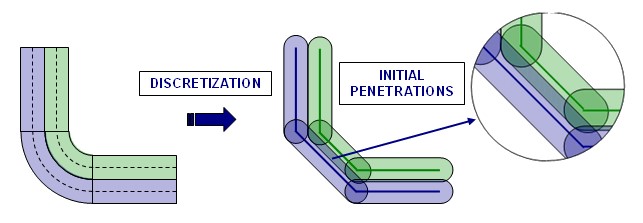

Начальные проникновения

В модели FE начальные проникновения очень распространены, неизбежны и являются результатом дискретизации во время процесса построения сетки (рисунок 332).

Рисунок 332: Начальные проникновения из-за дискретизации

Inacti

Специальная обработка начальных проникновений может быть выполнена с помощью флага Inacti. Можно удалить проникшие узлы из интерфейса или удалить основные сегменты, относящиеся к проникшим узлам. Оба способа обработки позволяют очень легко избавиться от начальных проникновений, но они могут привести к плохим результатам, если количество проникших узлов велико.

Установка Inacti на 3 позволяет PRADIOS Starter автоматически изменять координаты проникших узлов, чтобы избежать начальных проникновений. При этом следует соблюдать особую осторожность, поскольку эта операция может привести к изначально ограниченным пружинам.

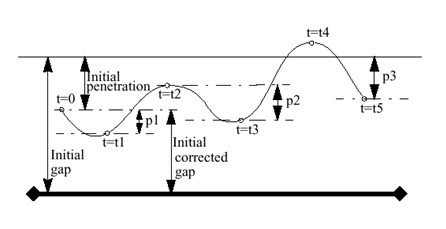

Также можно получить переменный зазор во времени, установив Inacti на 5. Иллюстрация на рисунке 333 объясняет, как эффективный зазор обновляется с учетом предыдущих проникновений.

Рисунок 333: Переменный зазор во времени

В момент t=0, если узел изначально проникает, его зазор автоматически исправляется. Затем этот «начальный исправленный зазор» будет увеличиваться каждый раз, когда узел удаляется от основного сегмента. Эта опция в основном используется для развертывания подушки безопасности, она обеспечивает приличный временной шаг в начале развертывания, тогда как все узлы сильно проникают.

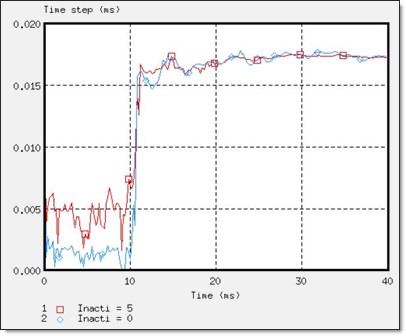

Рисунок 334: Временной шаг с использованием Inacti=5

Чтобы избежать высокочастотных эффектов, рекомендуется Inacti = 6 вместо Inacti =5.

Fpenmax

Fpenmax (максимальная доля начального проникновения) используется для работы с большим начальным проникновением. Жесткость узла будет отключена, если \(Penetration\geq F penmax\cdot Gap,\) , каким бы ни было значение Inacti.

Igap3 + %mesh_size

При \(I_{gap}\) = 3 и %mesh_size можно учесть размер сетки, чтобы избежать начальных проникновений. В этом случае переменная gap вычисляется как:

Где,

\(g_{m\_l}\) Длина меньшего края элемента

\(g_{s\_l}\) Длина меньшего края элементов, соединенных со вторичным узлом

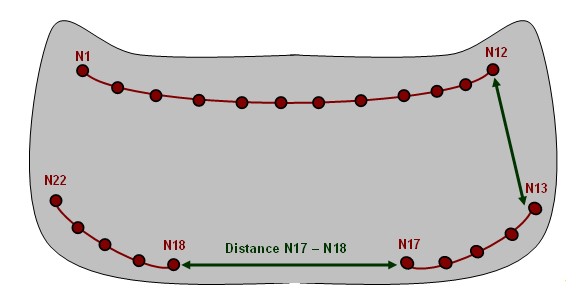

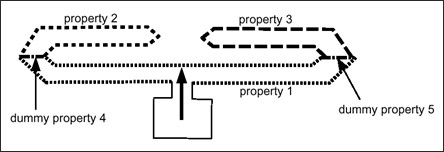

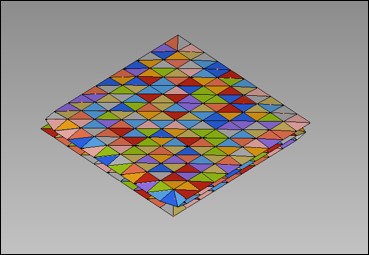

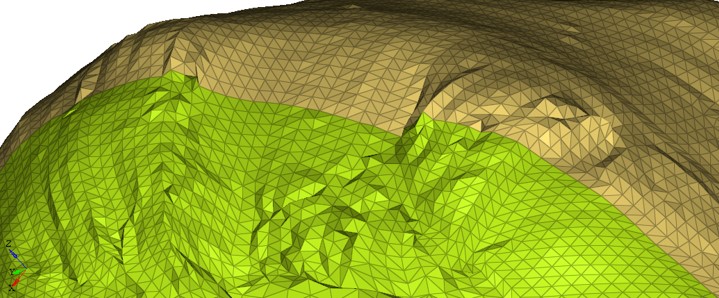

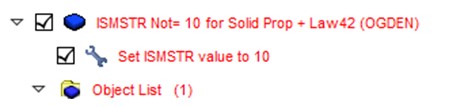

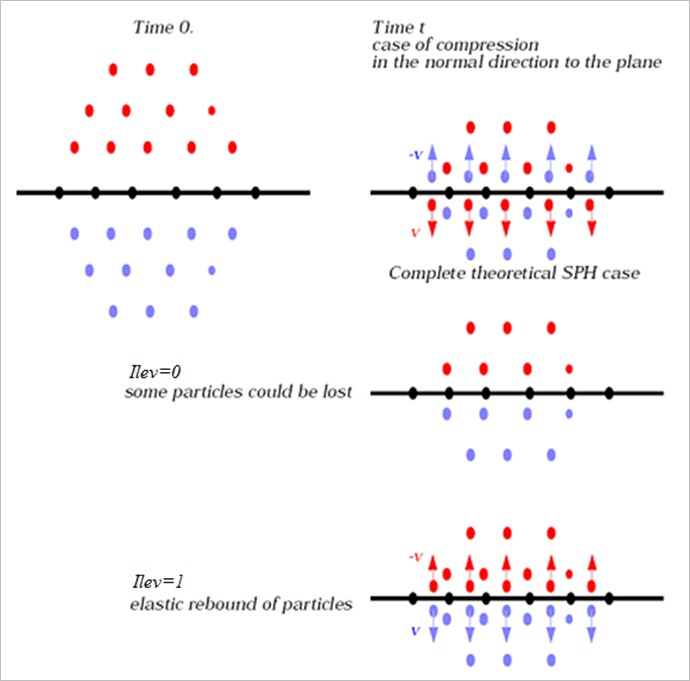

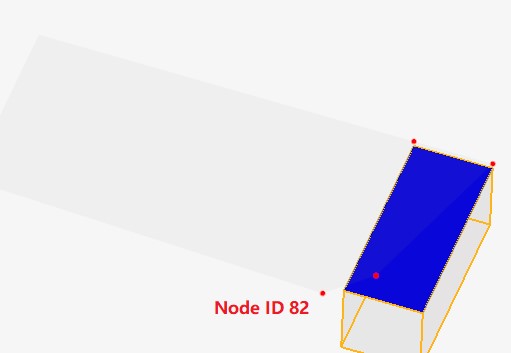

Irem_gap

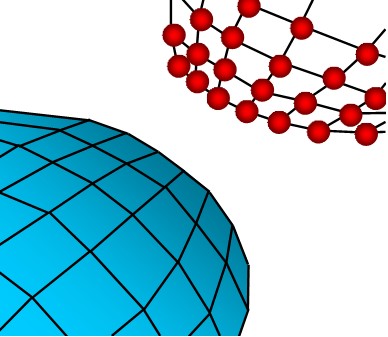

Опция Irem_gap используется для деактивации вторичных узлов, которые закрывают (Криволинейный \(Расстояние <\sqrt{2}\cdot Зазор\)) элементы. Эта опция полезна для самоударного контакта, когда размер сетки очень мал. .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image79.jpg

- width

3.28363in

- height

3.34196in

Рисунок 335: -1: Определение Irem_gap

настоятельно рекомендуется |

Жесткость интерфейса

Как и другие типы интерфейсов, при использовании метода штрафа интерфейс имеет пружинную жесткость, поскольку вторичный узел проникает в зазор; однако сила реакции вычисляется с гораздо лучшим приближением. Изменение силы в зависимости от проникновения узла нелинейно из-за возрастающей жесткости.

Рисунок 336: Изменение силы интерфейса в интерфейсе TYPE7

Жесткость интерфейса (K) не является постоянной, она увеличивается с проникновением. Более того, существует вязкое демпфирование, действующее на скорость проникновения. Контактная сила затем вычисляется как:

Мгновенная жесткость затем вычисляется как:

Узловой временной шаг может быть серьезно затронут, если проникновение велико. Жесткость, используемая для вычисления узлового временного шага, учитывает жесткость интерфейса.

Есть два способа уменьшить жесткость интерфейса:

Увеличение зазора

Увеличение начальной жесткости (с помощью флага Stfac)

Оба метода позволяют поглощать больше энергии при контакте и сглаживать удар. Увеличение зазора позволит узлам замедляться на большем расстоянии, поэтому проникновение уменьшается.

Комментарии

Даже если для моделирования выбран элементарный временной шаг, узловой временной шаг автоматически вычисляется, если есть интерфейс TYPE7. Для моделирования применяется наименьший временной шаг

2. В отличие от интерфейса TYPE5, Stfac меньше 1,0 создает большое проникновение при первом касании и приводит к высокой жесткости интерфейса и силе реакции. Чтобы избежать большого проникновения, рекомендуется Stfac больше или равно 1,0. .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image81.jpg

- width

3.57247in

- height

2.97879in

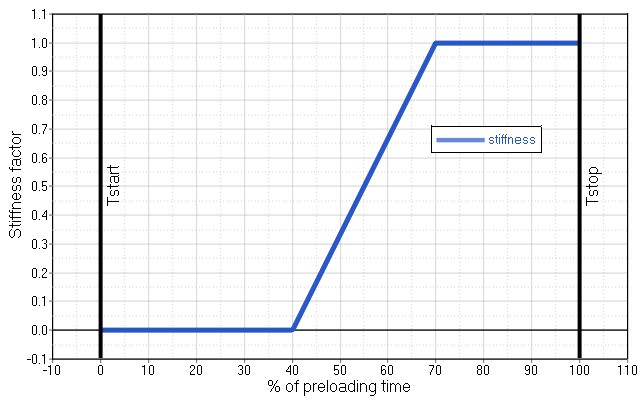

Рисунок 337: Кривые зависимости силы от проникновения

Хотя увеличение начальной жесткости приводит к меньшему временному шагу в начале проникновения, это увеличит временной шаг, если проникновение большое.

Трение

В PRADIOS доступно несколько формул трения. Самая простая, которая также является наиболее используемой, — это закон трения Кулона. Эта формулировка обеспечивает точные результаты при анализе столкновений и требует всего одного параметра (коэффициент трения Кулона, \(\mu\)).

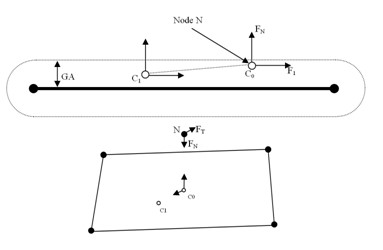

Рисунок 338: Нормальные и касательные силы, приложенные к узлу .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image84.jpg

- width

3.85368in

- height

2.1664in

Рисунок 339: Расчет силы адгезии

Значение по умолчанию для (:raw-latex:`\mu`) равно 0 (нет трения между поверхностями). Для расчета силы трения формула штрафа за трение по умолчанию является вязкой, основанной на тангенциальной скорости. Во время скользящего проникновения узел переходит из положения (C_{0}) (точка контакта в время (t)) в (C_{1}) (положение контакта в время (t+:raw-latex:`Delta `t)). Поскольку контакт вязкий, для расчета силы адгезии вводится коэффициент вязкости (C):

Где,

\(C=VIS_{F}\cdot\sqrt{2KM}\)

- K

Мгновенная жесткость интерфейса

- VIS

F Критический коэффициент демпфирования трения интерфейса

- M

Основная масса узла

После вычисления силы адгезии (Fh), если она меньше, чем \(mu F_{n,}\), сила трения не изменяется, равняясь Fh, и произойдет прилипание. Если сила адгезии больше, чем \(mu F_{n,}\), то сила трения уменьшается и равна \(mu F_{n.}\)

Рисунок 340: Расчет силы трения

Если скольжение происходит на очень низкой скорости (например: квазистатическое моделирование), вязкая формула не будет работать, поскольку сила трения вычисляется по тангенциальной скорости. Чтобы преодолеть это ограничение, доступна новая формула штрафа за трение, основанная на тангенциальном смещении (формула приращения жесткости). Этот метод вводит искусственную жесткость, K, для расчета изменения силы трения:

Где,

\(\delta_{t}\) Смещение по касательной

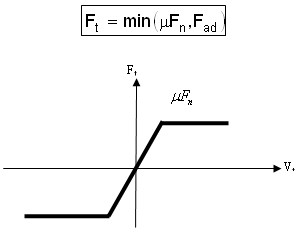

Поэтому, в отличие от предыдущей формулировки, формулировка жесткости способна вычислить правильную силу трения даже при низкой скорости. Рисунок 341 иллюстрирует этот момент. Если наложенное смещение применяется к детали (трехмерному кубу) при низкой скорости (0,01 м/с), вязкая формуляция не будет работать; тогда как формулировка жесткости, основанная на смещении по касательной, будет.

Рисунок 341: Формулировка вязкости против формулы жесткости

Доступны и другие формулы трения, их принцип похож на закон трения Кулона. PRADIOS сначала вычисляет силу адгезии, которая затем сравнивается с \(\mu F_{n}\). Их различия заключаются в коэффициенте трения (\(\mu\)), который больше не является постоянным, а зависит от давления нормальной силы на основной сегмент и от тангенциальной скорости вторичного узла. В зависимости от флага \(I_{\text{{{fric}}}}\) доступны три новые формулы трения:

Обобщенный закон вязкого трения

Модифицированный закон трения Дармстада

Закон трения Ренара

Если

Если

Если

|

Рисунок 342: Графическое представление модели трения Ренара

Теплообмен

В интерфейсе TYPE7 есть три теплообмена: теплопередача, излучение и тепловое трение разрешены \(I_{the}\) =1.

Для теплопередачи между вторичным и основным с Iform_the можно определить два различных теплообмена. Один из них задает постоянную температуру в интерфейсе, где теплообмен происходит только между этим интерфейсом и вторичной стороной оболочки. Другой — теплообмен между всеми частями в контакте.

Если Frad≠ 0, то излучение вычисляется внутри расстояния Drad (макс. расстояние для вычисления излучения). Рекомендуется не устанавливать слишком большое значение для Drad , иначе производительность PRADIOS Engine может снизиться.

Использование Fheats и Fheatm фрикционной энергии скольжения будет преобразовано в тепло. Поскольку тепло трения делится между вторичной и основной стороной, обычно Fheats + Fheatm < 1,0. Тепло трения QFric определяется:

Если IForm =2 (формуляция жесткости):

Вторичная сторона: .. math:: Q_{Fric}=Fheat_{s}cdotfrac{left(F_{textit{adh}}-F_{t}right)}{K}cdot F_{t} tag{234}

Основная сторона:

(Ithe_form=1)

Здесь K — это Жесткость контакта \(F_{adh}\)

Если IForm =1 (формуляция штрафа):

Вторичная сторона:

Основная сторона:

Управление шагом времени интерфейса

В предыдущем разделе объясняется, что шаг времени может быть серьезно уменьшен во время контакта, поскольку жесткость добавляется ко всем проникающим узлам. Более того, чтобы предотвратить прохождение любого узла через основной сегмент в течение одного цикла, также вычисляется кинематический шаг времени. Если скорость удара узла достаточно высока, чтобы пройти через сегмент за один цикл, PRADIOS уменьшает шаг времени, чтобы применить штрафную силу, когда узел находится на расстоянии зазора. Если p — это расстояние проникновения, то dp/dt — это скорость проникновения, а кинематический временной шаг — это необходимое время для того, чтобы узел прошел половину расстояния между узлом и сегментом. Узловой временной шаг также вычисляется для обеспечения численной стабильности. Наименьший временной шаг затем используется для моделирования.

Узловой шаг времени во время контакта:

Кинематический шаг времени: .. math:: dt_{kin}=frac{1}{2}biggl{[}frac{Gap-p}{dp/dt}biggr{]}tag{239}

Если по какой-то причине узел сильно проник, либо шаг по времени узла, либо шаг по времени кинематики может быть очень низким. Тогда можно

освободить этот узел от интерфейса, используя опцию /DT/ INTER/DEL в

файле Engine. Все узлы, достигающие dtmin, будут удалены из интерфейса.

Увеличение массы

Использование масштабирования массы (/DT/NODA/CST) может привести к нестабильности массы.

По мере проникновения узла его глобальная жесткость увеличивается (добавляется мгновенная

жесткость интерфейса, Kt); поэтому его узловой шаг по времени

уменьшается. Чтобы соответствовать минимальному шагу по времени, PRADIOS добавляет

необходимую массу к узлу. К сожалению, эта добавленная масса увеличивает

кинетическую энергию, и проникновение становится больше.

Рисунок 343: Влияние масштабирования массы на интерфейс TYPE7

Если интерфейс не способен остановить проникновение, добавленная масса (из-за масштабирования массы) будет продолжать становиться все больше и больше. Поэтому, вычисление, скорее всего, остановится, поскольку изменение массы может стать огромным очень быстро (несколько циклов). Если это так, интерфейс следует модифицировать:

Зазор следует увеличить

Начальную жесткость можно увеличить

Сетку следует модифицировать, чтобы она была более тонкой и однородной в зоне контакта

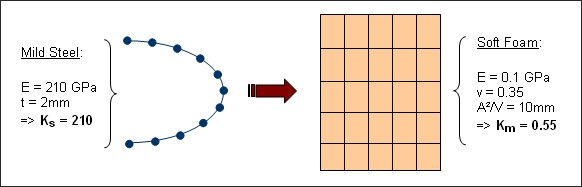

Мягкая часть против твердой части

Значение жесткости по умолчанию, вычисленное PRADIOS, часто подходит для избежания очень высокого проникновения, приводящего к падению шага по времени. Когда происходит контакт между похожими материалами, нет проблем с использованием жесткости по умолчанию; за исключением случаев, когда материалы различаются. Например, когда мягкая сталь сталкивается с мягкой пеной, жесткость по умолчанию может быть слишком низкой, чтобы избежать большого проникновения. Когда такие контакты желательны, рекомендуется сначала вычислить отношение жесткости вторичного материала к жесткости основного материала. Если это отношение больше 100, следует использовать масштабный коэффициент (Stfac), равный этому отношению, для увеличения жесткости интерфейса.

Рисунок 344: Удар между сталью и пеной

На рисунке 344 показан контакт между мягкой сталью и мягкой пеной. Коэффициент жесткости больше 380, в таком случае, когда основная сторона является мягкой стороной, флаг Stfac может быть установлен на 380, чтобы избежать очень высоких проникновений.

Блокировка удара кромка к кромке

Интерфейс TYPE7 не справляется с ударом кромка к кромке. Ограничение этого интерфейса во время контакта кромка к кромке показано на Рисунок 345.

Рисунок 345: Контакт края с краем

Когда сетка достаточно мелкая, за проникновением края с краем часто следует контакт узла с оболочкой. Основная проблема при ударе края с краем — это ситуации блокировки. Если после проникновения края происходит изменение нагрузки, блокировка неизбежна, поскольку обнаруживается контакт узла с поверхностью (Рисунок 346). Обычно это приводит к высокому проникновению; поэтому анализ останавливается по мере уменьшения временного шага. Если происходит блокировка, необходимо использовать интерфейс TYPE11 в этой области для решения проблемы.

Рисунок 346: Блокировка после проникновения через край

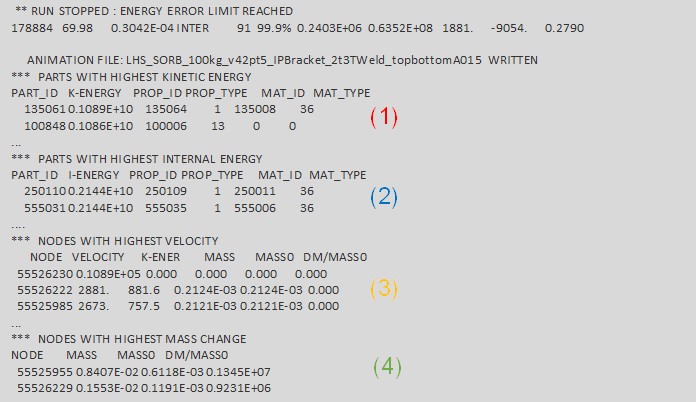

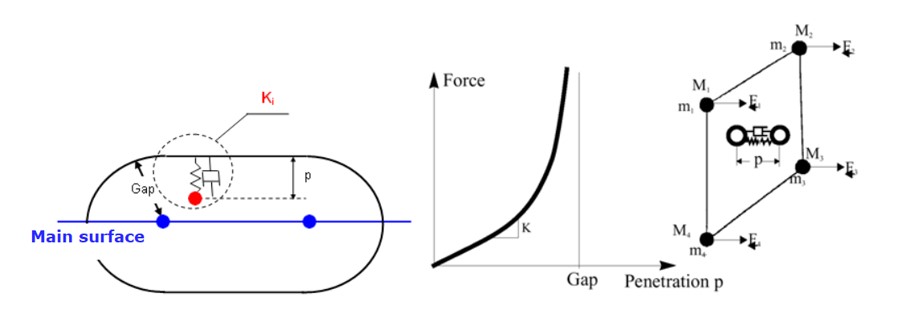

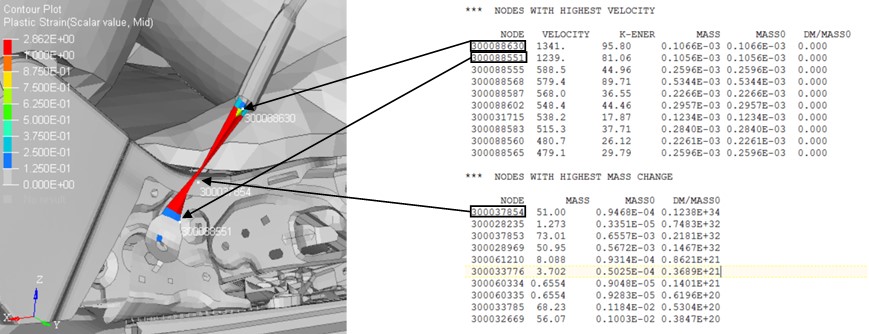

Создание тангенциальной силы

Тангенциальная сила может быть создана, когда проникший узел скользит без трения. Такое поведение обусловлено зазорами, перекрывающимися вокруг краев. Рисунок 347 иллюстрирует, что из-за цилиндрического зазора вокруг краев сила больше не является нормальной к средней поверхности оболочки. .. image:: vertopal_7197fe79ded4471fa6ba70c4c62a5530/media/image92.jpg

- width

5.68679in

- height

1.78103in

Рисунок 347: Генерация тангенциальной силы

Комментарии

Всегда рекомендуется выполнять постобработку контактных сил. Если они слишком велики, принимая во внимание физическое понимание, модель должна быть проверена.

Для постобработки сил для симметричного контакта интерфейс можно разделить на четыре интерфейса. Например, для двух частей A и B можно создать: - Интерфейс 1 с A вторичным и B основным

+Интерфейс 2 с A основным и B вторичным

+Интерфейс 3 с A основным и вторичным

+Интерфейс 4 с B основным и вторичным

Предупреждение о зазоре автоматического контакта

Это предупреждение следует принимать во внимание только для самоударного интерфейса.

При моделировании автоконтакта настоятельно рекомендуется использовать минимальный зазор не менее половины наименьшего края сегмента. Сообщение означает, что по крайней мере один элемент на основной стороне имеет длину стороны меньше, чем в два раза больше GAP, и существует риск чрезмерной жесткости.

ИДЕНТИФИКАТОР ПРЕДУПРЕЖДЕНИЯ: 94 ** ПРЕДУПРЕЖДЕНИЕ В ИНТЕРФЕЙСЕ GAP ВХОДНОЙ GAP 1.7 ОДНАКО РЕКОМЕНДУЕТСЯ, ЧТОБЫ GAP БЫЛ МЕНЬШЕ 1 |

Рисунок 348 иллюстрирует самоударное взаимодействие, для которого GAP

равняется половине длины стороны элемента. Если этот элемент сжат

более чем на 50%, красный узел входит в зазор соседнего

элемента; затем обнаруживается самоконтакт, которого быть не должно.

Это приводит к чрезмерной жесткости конструкции.

Рисунок 348: Рекомендуемый зазор при моделировании автоконтакта

Если длина стороны, L элемента меньше, чем GAP, самоконтакт будет даже вычислен с начала

вычисления.